Layered cocoon cooking method

A cocoon boiling and silkworm cocoon technology, applied in silk reeling, etc., can solve the problems of uneven unraveling of silkworm cocoons, and achieve the effects of avoiding excessive degumming, uniform loosening, and preventing overcooking of cocoons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

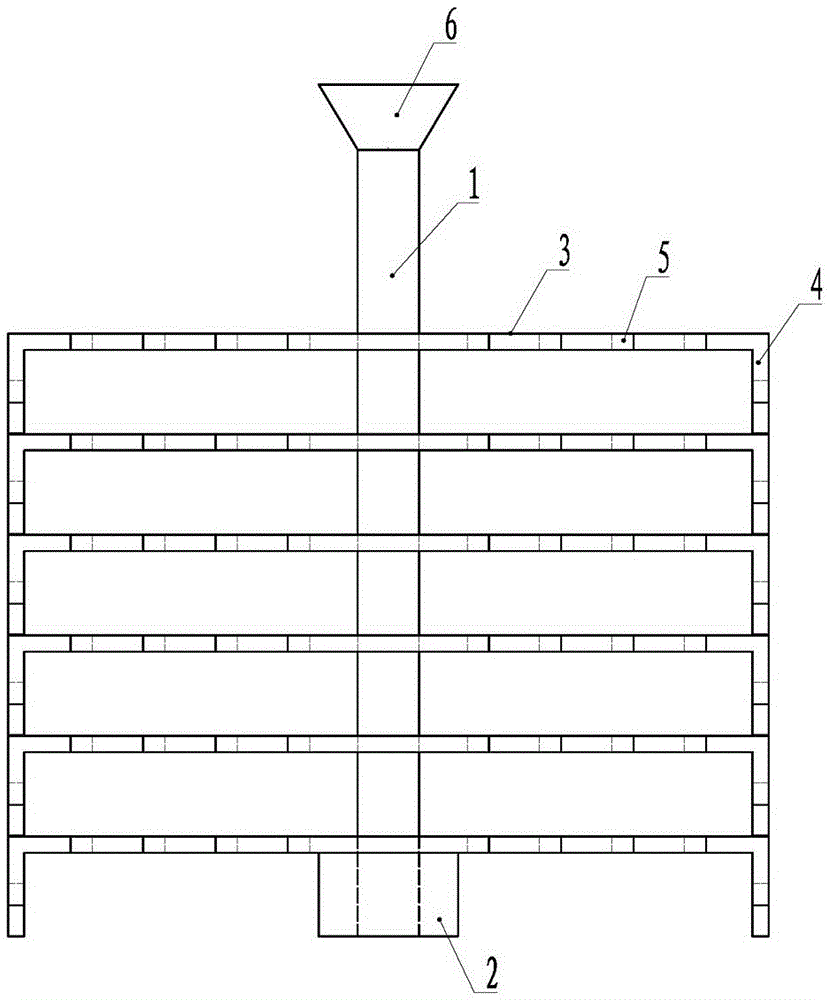

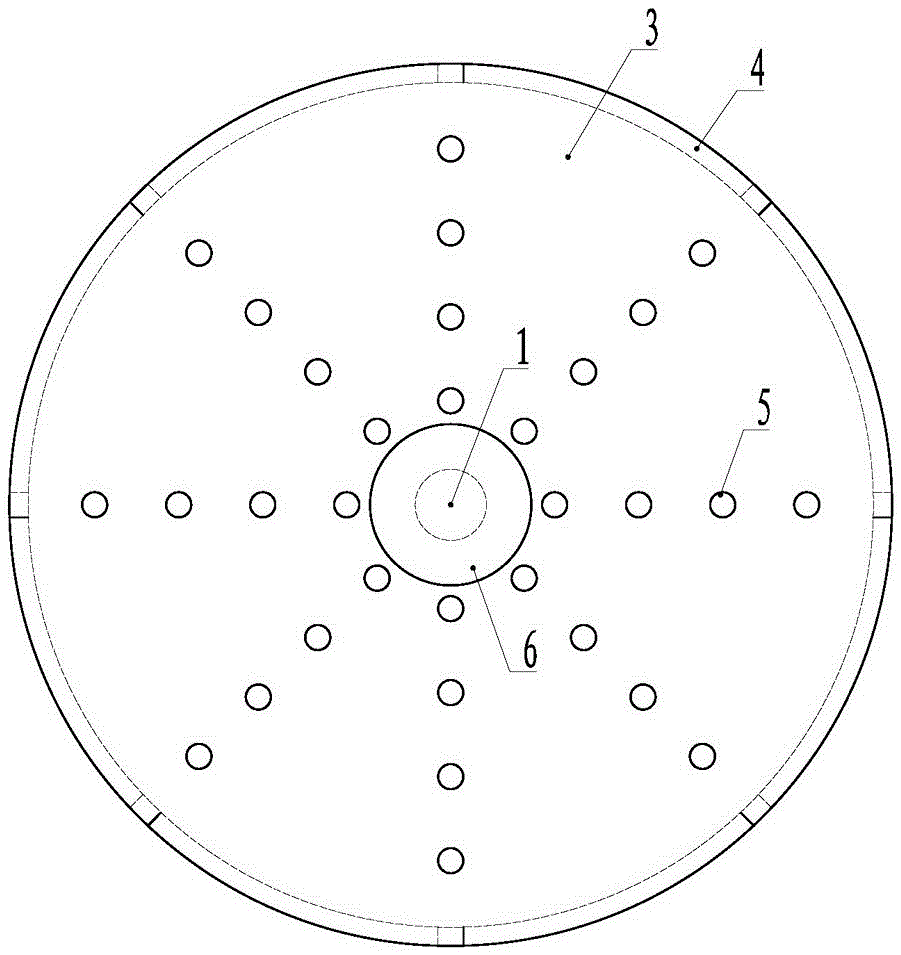

[0016] A layered cocoon cooking method using a method such as figure 1 and figure 2 The layered cocoon cooking device shown includes a support column 1 with a limit block 2 at the bottom. The support column 1 is sequentially set with a plurality of cocoon trays above the limit block 2. The cocoon tray is provided with The disk surface 3, and the surrounding edge 4 vertically extending downwards from the edge of the disk surface 3, the disk surface 3 and the surrounding edge 4 are all provided with a plurality of through holes 5; the height of the surrounding edge 4 is greater than or equal to the height of the limit block 2, and the supporting column 1 is fitted with a handle 6 at the top;

[0017] This layered cooking cocoon method comprises the following steps:

[0018] A. Soaking: Soak the cocoons in pure water at 40°C for 3 minutes to fully moisten the cocoons;

[0019] B. Cooking: place the silkworm cocoons on the layered cocoon cooking device, and place the silkworm ...

Embodiment 2

[0022] A layered cocoon cooking method, using the same layered cocoon cooking device as in Example 1;

[0023] This layered cooking cocoon method comprises the following steps:

[0024] A. Soaking: Soak the cocoons in pure water at 50°C for 5 minutes to fully moisten the cocoons;

[0025] B. Cooking: place the silkworm cocoons on the layered cocoon cooking device, and place the silkworm cocoons on the disk surface 3 of the cocoon tray at different positions according to the thickness and size of the silkworm cocoons, and place the thicker and larger ones At the bottom layer, the thinner and smaller cocoons are placed on the top layer, and the number of cocoons placed on each layer is evenly spaced, and then the layered cocoon cooking device with silk cocoons is placed in a cocoon cooking pot filled with pure water for cooking. After the pure water in the pot reaches boiling state, continue to cook for 8 minutes to fully dissolve the cocoons;

[0026] C. Cooling down: take ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com