Single-steel multi-level hot-rolled complex-phase high-strength steel plate and production method thereof

A technology of high-strength steel plate and production method, which is applied in the field of hot-rolled high-strength high-strength steel plate and its production, can solve the problems of high capacity requirements for coiling equipment, poor production conditions, and complicated procedures, and achieve good bake hardening performance, The production control is less difficult and the effect of uniform mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

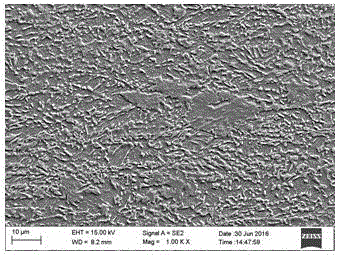

[0043] Example 1: The specific production process of the multi-stage hot-rolled multi-phase high-strength steel plate of Benyi Steel is as follows.

[0044] (1) Steelmaking and casting: The weight percentage of the chemical composition of the molten steel is: C 0.10%, Mn 2.5%, S0.012%, P 0.025%, Si 0.8%, Als 0.04%, Cr 0.60%, Ti 0.015% , Mo 0.10%, N 0.005%, and the rest are iron and unavoidable impurities. In the casting step, the superheat of molten steel is 30°C; under dynamic light pressure, the crystallizer liquid level fluctuation is stably controlled within ± 2mm.

[0045] (2) Heating process: the slab is heated to 1270-1300°C, held for 3.0 hours, the descaling temperature after the furnace is 1130°C, and the temperature difference between the head and tail of the slab is ≤20°C.

[0046] (3) Hot rolling process: the starting temperature of finish rolling is 1040±10°C, the temperature of finishing rolling is 890±10°C, and the thickness of the rolled steel plate is 8.0mm. ...

Embodiment 2

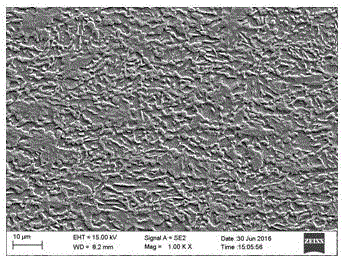

[0052] Example 2: The specific production process of the multi-stage hot-rolled multi-phase high-strength steel plate of Benyi Steel is as follows.

[0053] (1) Steelmaking and casting: The weight percentage of the chemical composition of the molten steel is: C 0.08%, Mn 1.80%, S0.006%, P 0.012%, Si 1.0%, Als 0.045%, Cr 0.80%, Ti 0.035% , Mo 0.3%, N 0.006%, and the rest are iron and unavoidable impurities. In the casting step, the superheat of molten steel is 25°C; under dynamic light pressure, the crystallizer liquid level fluctuation is stably controlled within ± 2mm.

[0054] (2) Heating process: The slab is heated to 1250-1270°C, held for 2.5 hours, the descaling temperature after the furnace is 1135°C, and the temperature difference between the head and tail of the slab is ≤20°C.

[0055] (3) Hot rolling process: the starting temperature of finish rolling is 1090±10°C, the temperature of finishing rolling is 870±10°C, and the thickness of the rolled steel plate is 1.8mm. ...

Embodiment 3-7

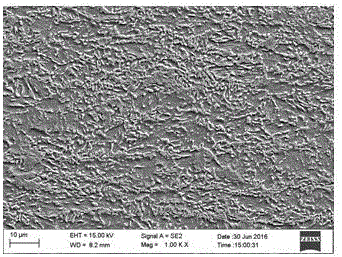

[0061] Embodiment 3-7: The specific production process of the multi-stage hot-rolled multi-phase high-strength steel plate of Benyi Steel is as follows.

[0062] Except for the step (6) annealing process, the others are the same as in Example 1; the specific process of the step (6) annealing process is shown in Table 1.

[0063] Table 1: Annealing process of embodiment 3-7

[0064] Example 3 Example 4 Example 5 Example 6 Example 7 Annealing temperature / ℃ 1000 900 900 950 1000 Holding time / h 3 5 3 2 2.5 cooling method baked air-cooled baked air-cooled Cooling with the furnace Cooling with the furnace Cooling with the furnace

[0065] The metallographic structure obtained in Examples 3-7 is ferrite-martensite-a small amount of retained austenite, and the performance indexes of the multiphase high-strength steel plate are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com