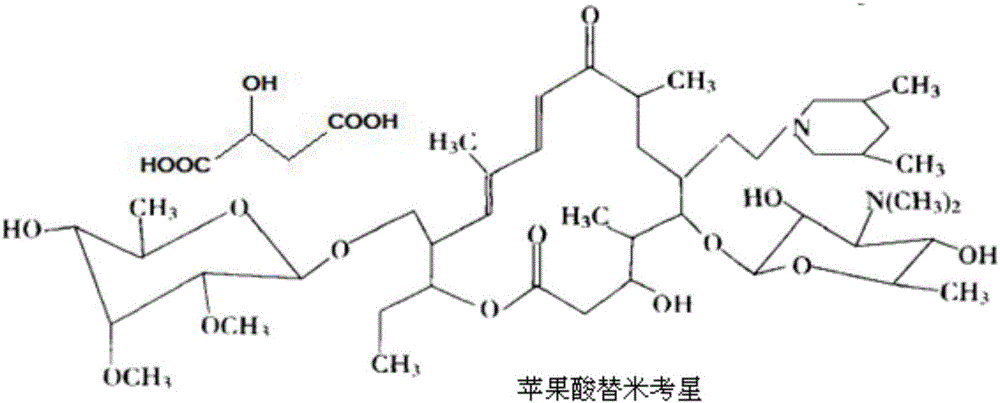

Preparation method of malic acid and tilmicosin compound salt

A technology of tilmicosin and malic acid, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of increasing the use cost, reducing the curative effect of diseases, complex preparation process, etc., and achieves easy operation, The effect of good water solubility and simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Put 0.67g of malic acid and 50ml of acetone in a 250ml three-neck flask, and under anhydrous conditions, stir and heat in an oil bath at 56°C for 10min to dissolve malic acid in acetone;

[0027] (2) equimolar tilmicosin crude drug 4.35g is dissolved in 30ml acetone, dissolves under anhydrous condition, makes the acetone solution of tilmicosin;

[0028] (3) The acetone solution of tilmicosin is transferred to the Soxhlet extractor, and the beaker is cleaned in stages with 10ml of acetone, and the washing solution is incorporated into the Soxhlet extractor; the Soxhlet extractor is connected to the side port of the three-necked flask, The middle port of the three-necked flask is connected to a condenser (to ensure no water), and the end of the condenser is connected to a drier (to prevent water in the air from entering). After the oil bath is heated to 56 ° C, under anhydrous conditions, the acetone of tilmicosin The solution was slowly dripped into the acetone solut...

Embodiment 2

[0032] (1) Put 0.67g of malic acid and 50ml of dichloromethane in a 250ml three-neck flask, and under anhydrous conditions, stir and heat in an oil bath at 50°C for 10 minutes to dissolve malic acid in dichloromethane;

[0033] (2) Equimolar tilmicosin crude drug 4.35g is dissolved in 30ml dichloromethane, dissolves under anhydrous condition, makes the dichloromethane solution of tilmicosin;

[0034] (3) Transfer the dichloromethane solution of tilmicosin to the Soxhlet extractor, wash the beaker with 10ml of dichloromethane in stages, and incorporate the washing solution into the Soxhlet extractor; connect the Soxhlet extractor to the three-necked flask On the side port of the three-neck flask, the middle port of the three-neck flask is connected to the condenser (to ensure that there is no water), and the end of the condenser is connected to the dryer (to prevent the water in the air from entering). The dichloromethane solution of Coxin is slowly dropped into the dichloromet...

Embodiment 3

[0037] (1) Dissolve 0.67g of malic acid in 50ml of ethyl acetate, stir and heat to dissolve in an oil bath at 60°C for 10min under anhydrous conditions, to obtain an ethyl acetate solution of malic acid;

[0038] (2) Equimolar tilmicosin crude drug 4.35g is dissolved in 50ml ethyl acetate, dissolves under anhydrous condition, makes the ethyl acetate solution of tilmicosin;

[0039] (3) Place the ethyl acetate solution of tilmicosin in a 250ml three-necked flask, add a stirrer, fix it in a constant temperature magnetic stirrer, connect the three-necked flask to the condensing device, and fill it with the tail gas of anhydrous calcium chloride Processing device, a dropping funnel filled with ethyl acetate solution of malic acid; after the oil bath is heated to 70°C, under anhydrous conditions, adjust the dropping speed of the dropping funnel, and add the ethyl acetate solution of malic acid to Slowly drop 0.5ml / min into the ethyl acetate solution of tilmicosin for reaction; afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com