A kind of manufacturing process of anti-seepage and pollution tile

A production process and ceramic tile technology, which is applied in the field of tile processing, can solve the problems of troublesome maintenance and low processing efficiency of tiles, and achieve the effects of reducing the scraping process, improving processing efficiency, and speeding up the drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below by means of specific embodiments:

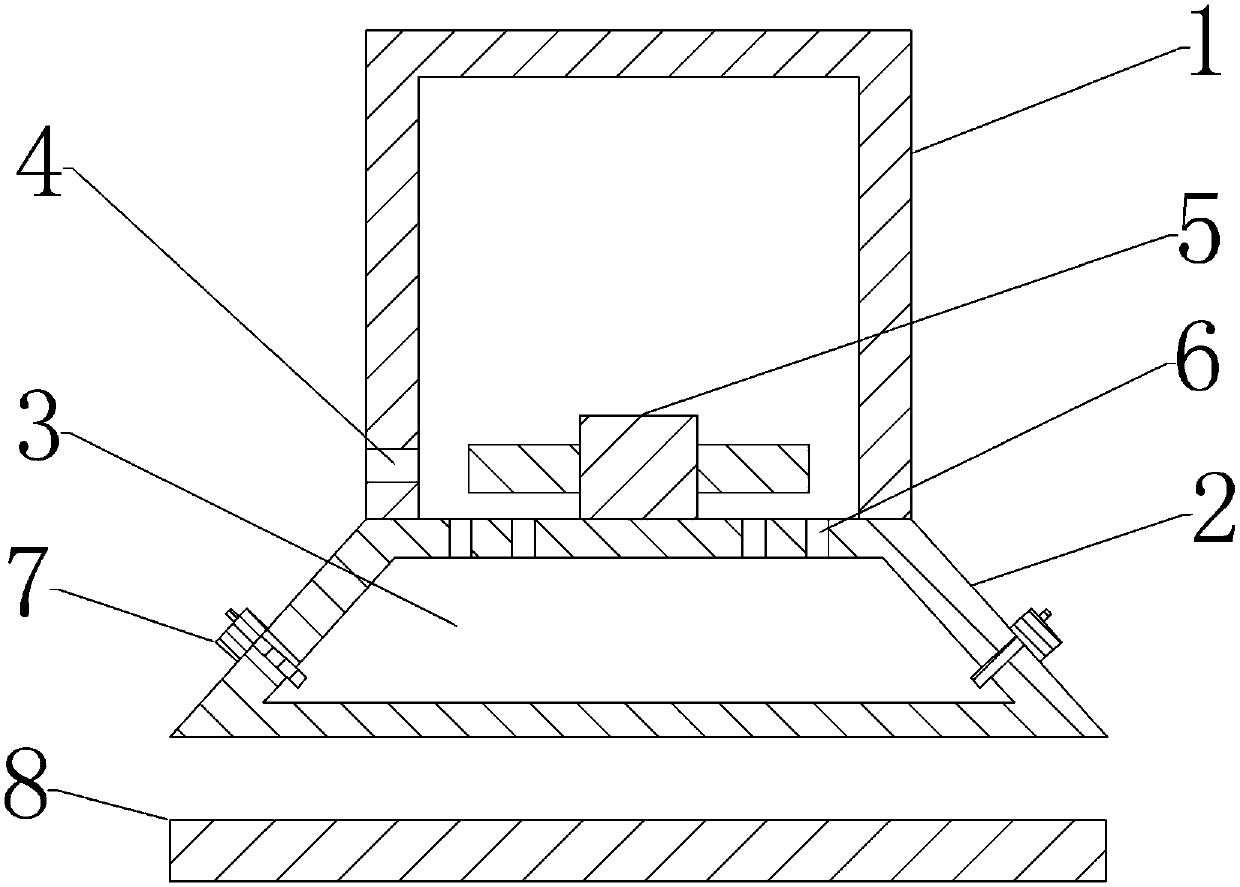

[0025] The reference signs in the drawings of the specification include: fixed shaft 1, working disc 2, cavity 3, feed inlet 4, impeller 5, through hole 6, material spraying device 7, ceramic tile 8.

[0026] This embodiment is a manufacturing process of the anti-seepage and pollution ceramic tile 8. After the ceramic tile 8 is fired, the following processing steps are required:

[0027] (1) Pre-cut the edge, cut the tile 8 into a square with a length of 100cm and a width of 100cm.

[0028] (2) Anti-seepage treatment, using potassium methyl silicate solution as a waterproofing agent, and applying it on the surface of the ceramic tile 8 to prevent calcium carbonate and other high-calcium-alkaline substances on the surface of the ceramic tile 8 from interfering with the hydration of nano-silica.

[0029] (3) Antifouling treatment, using an antifouling treatment device to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com