Multi-print head printing and integrated manufacturing method of LTCC (low temperature co-fired ceramic) filter

A manufacturing method and filter technology, which can be applied to waveguide-type devices, electrical components, circuits, etc., can solve the problems of inflexible manufacturing, complicated processes, and many processes, and achieve the effect of less equipment, simple process, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

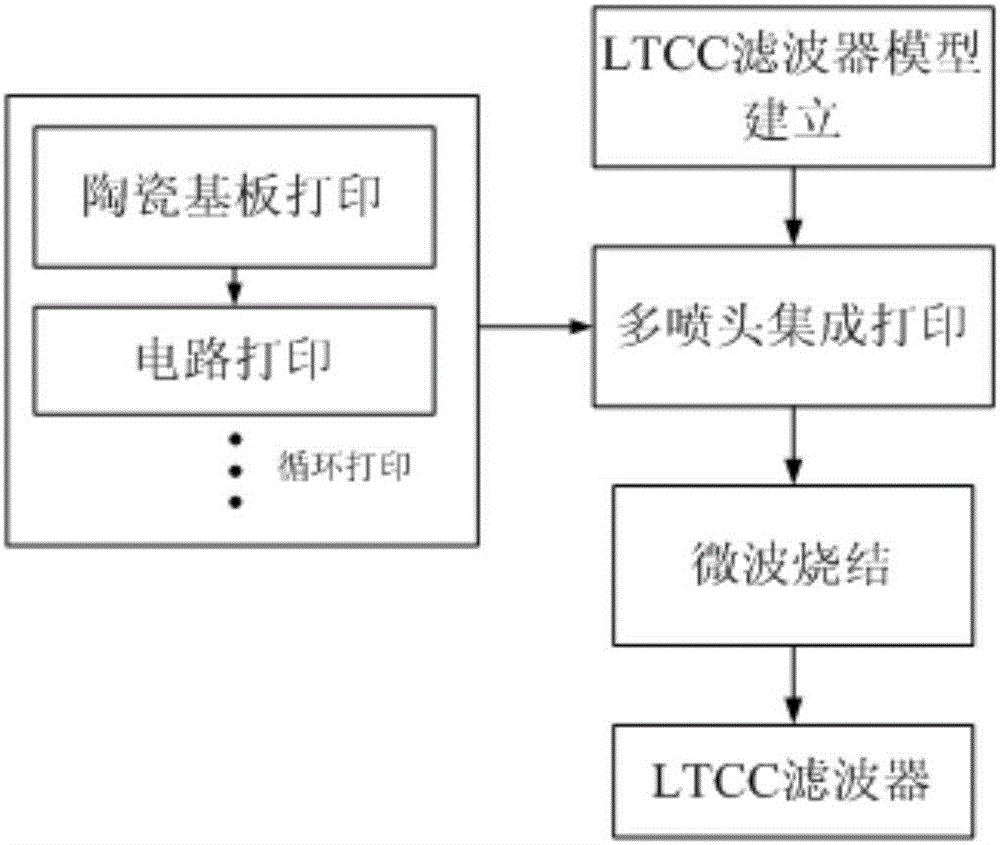

[0021] Implementation: 1: A kind of LTCC filter multi-jet printing integrated manufacturing method, comprising the following steps:

[0022] Step 1, establish the LTCC filter CAD model in the 3D printer;

[0023] Step 2. Prepare ceramic substrate materials and circuit printing materials and put them into the corresponding barrel of the 3D printer;

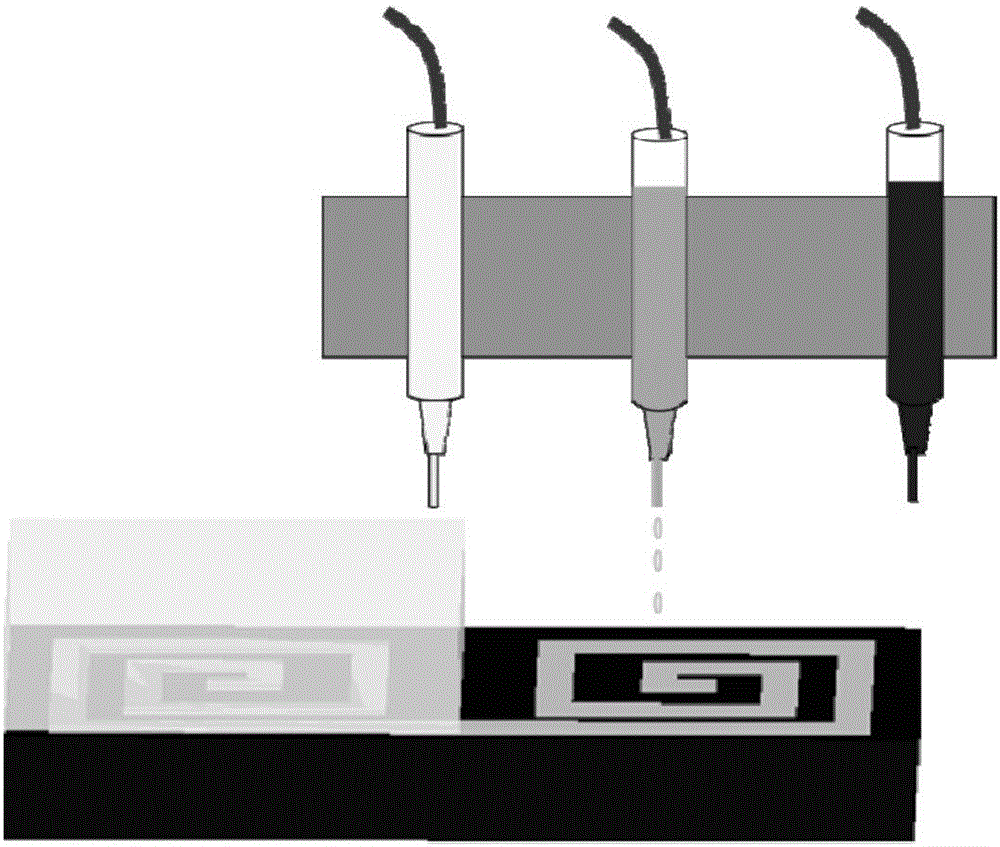

[0024] Step 3, multi-layer LTCC filter printing, first print a substrate with a required thickness on the receiving platform with a nozzle equipped with ceramic materials, and then print the required circuit on the previously printed substrate with a nozzle equipped with circuit printing materials The internet;

[0025] In the above step 3, the ceramic substrate material is printed by extrusion molding process, the material is extruded through the tiny needle by air pressure, the printing height ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com