Method for strengthening anaerobic digestion treatment of molasses alcohol wastewater

A technology for molasses alcohol wastewater and anaerobic digestion, which is applied in anaerobic digestion treatment, food industry wastewater treatment, natural water treatment and other directions, to achieve good research and application prospects, improve efficiency, and be easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

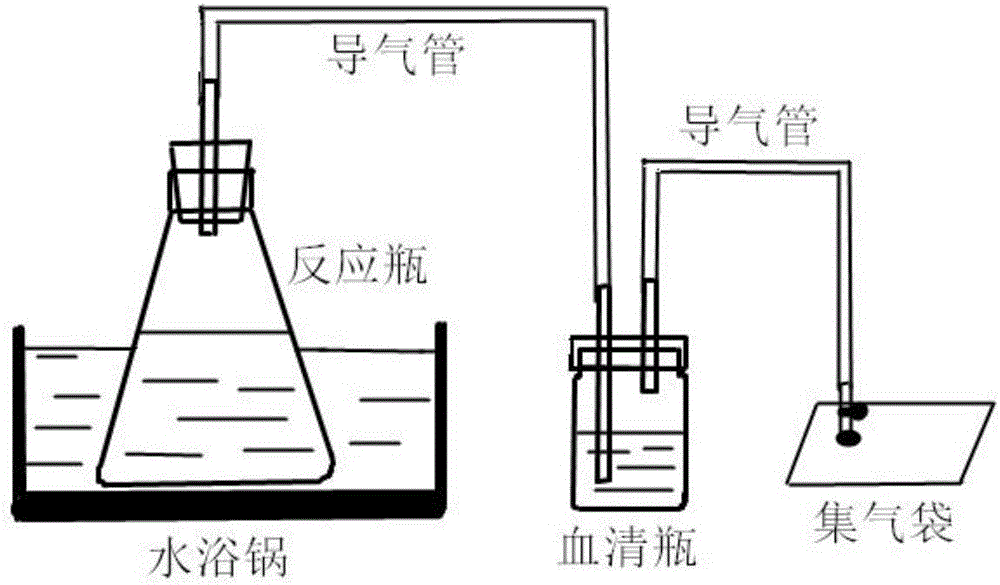

Method used

Image

Examples

Embodiment 1

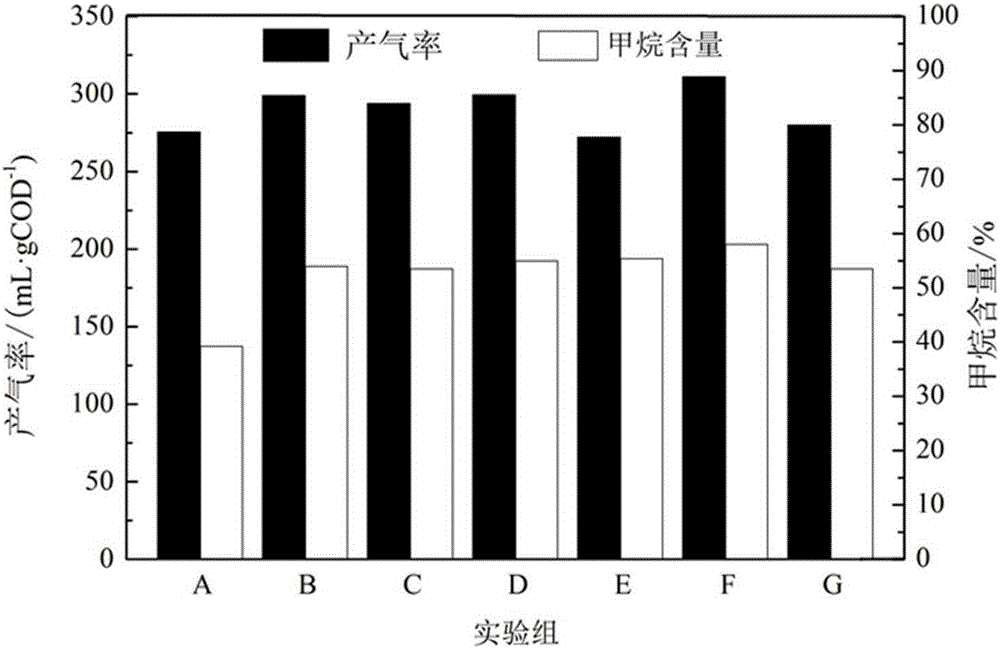

[0037] After the anaerobic digestion reaction experiment of embodiment 1 finishes, calculate gas production rate according to the degradation amount of COD, every group produces biogas rate and methane content in gas as image 3 . Depend on image 3It can be seen that at the end of the reaction, the gas production rate of the blank group was 275.3mL / g COD, and the methane content in the gas was 39.2%. , 299.3mL / gCOD, 272.0mL / gCOD, 310.9mL / gCOD, 279.8mL / gCOD and 54.0%, 53.5%, 55%, 55.4%, 58%, 53.5%. It shows that adding NZVI to anaerobic digestion system can reduce the inhibitory effect of hydrogen sulfide on MPB. Group F had the highest gas production rate, 35.6mL / g COD higher than the blank group, and the highest methane content in the gas, 58%, 18.8% higher than the blank group. It shows that when the addition amount of NZVI is 0.50g, the anaerobic digestion treatment effect of molasses alcohol wastewater is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com