Method for producing soda ash and co-producing gypsum and basic magnesium carbonate by using mirabilite and dolomite

A technology of dolomite and magnesium carbonate, applied in the direction of magnesium carbonate, alkali metal carbonate, chemical instruments and methods, etc., can solve the problems of low raw material utilization rate, high production cost, and waste discharge, and achieve high cost performance and production The effect of short cycle time and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

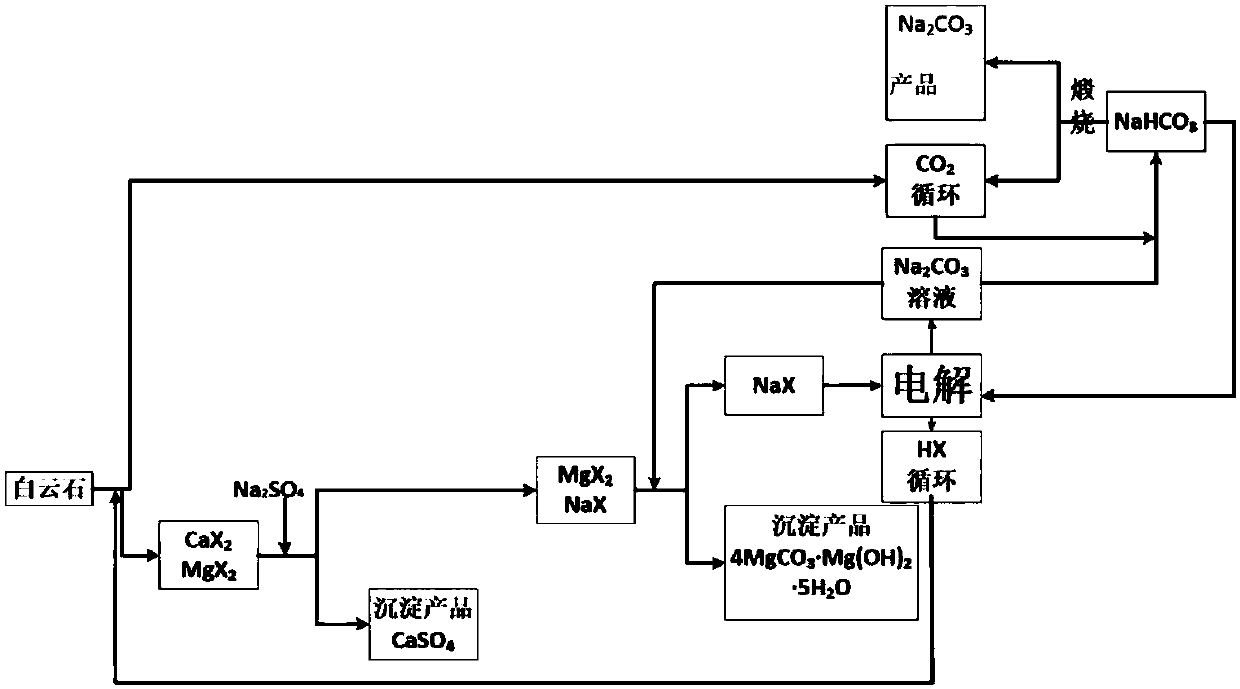

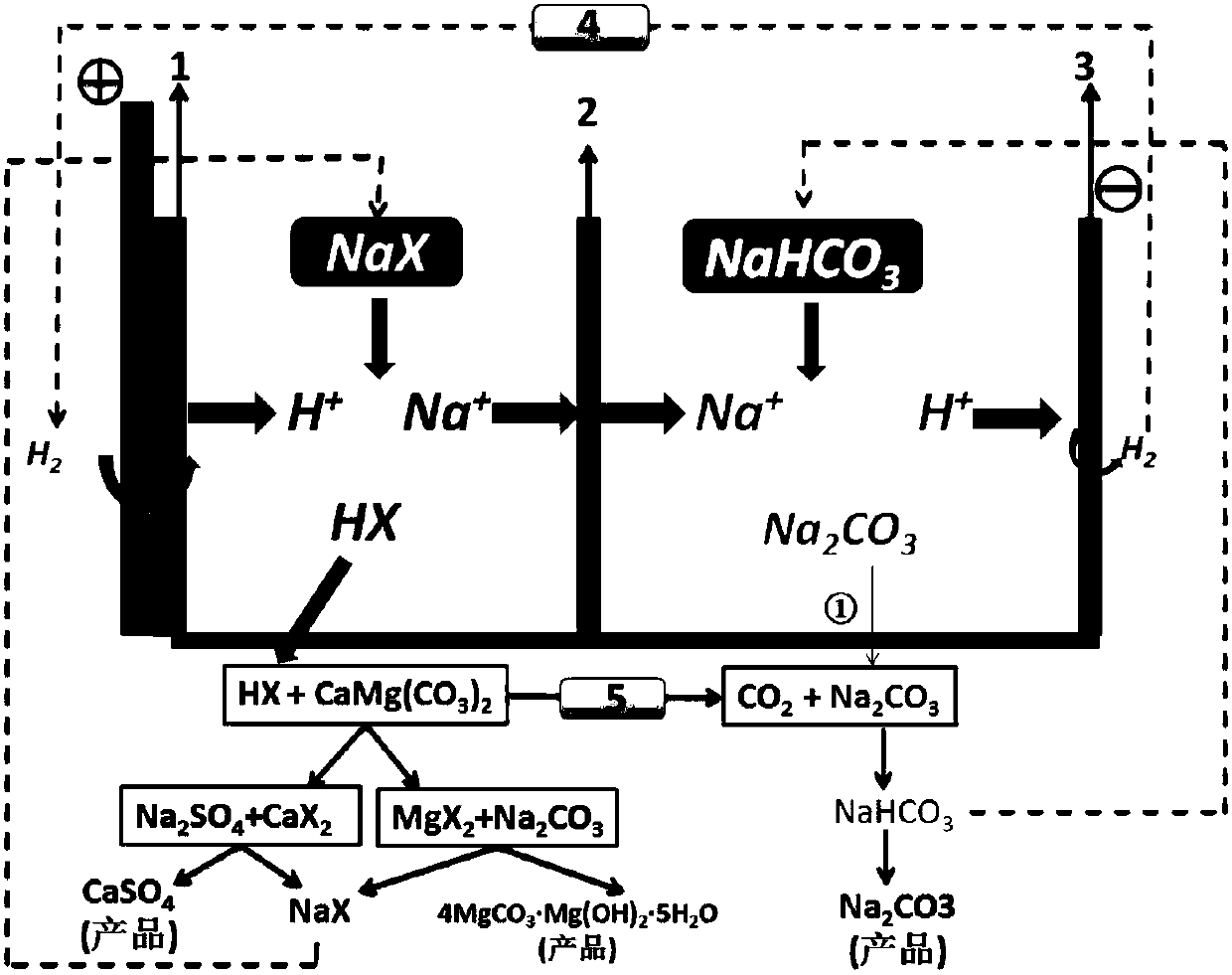

[0047] The process and principle of this embodiment are as attached figure 1 with 2 Shown. The electrolytic cell is divided into two areas, an anode area and a cathode area, by a cation exchange membrane 2 that only allows cations to pass through but can prevent anions from passing through. Add 40ml of NaAc solution with a concentration of 3.2mol / L in the anode zone as the anolyte, and add 120ml of saturated NaHCO with a concentration of 1.14mol / L in the cathode zone 3 The solution is used as the electrolyte and at the same time as the reaction material, and 400mA direct current is applied. A gas diffusion electrode is used as the anode electrode 1, and a metal nickel electrode is used as the cathode electrode 3. Use a syringe syringe to draw 0.5ml of anolyte every 10-20min to determine the hydrogen ion concentration. When the hydrogen ion concentration in the solution is higher than 3.168mol / L, take out the catholyte and anolyte separately. At this time, the anolyte is HAc so...

Embodiment 2

[0052] The process of this embodiment is as attached figure 1 with 2 Shown. The electrolytic cell is divided into two areas, an anode area and a cathode area, by a cation exchange membrane 2 that only allows cations to pass through but can prevent anions from passing through. Add 40ml of NaAc solution with a concentration of 1.6mol / L in the anode zone as the anolyte, and add 60ml of saturated NaHCO with a concentration of 1.14mol / L in the cathode zone 3 The solution is used as the electrolyte and at the same time as the reaction material, and 400mA direct current is applied. A gas diffusion electrode is used as the anode electrode 1, and a metal nickel electrode is used as the cathode electrode 3. Use a syringe syringe to draw 0.5ml of anolyte every 10 to 20 minutes to determine the hydrogen ion concentration. When the hydrogen ion concentration in the solution is higher than 1.52mol / L, take out the cathode and anolyte respectively. At this time, the anolyte has a concentration...

Embodiment 3

[0057] The process of this embodiment is as attached figure 1 with 2 Shown. The electrolytic cell is divided into two areas, an anode area and a cathode area, by a cation exchange membrane 2 that only allows cations to pass through but can prevent anions from passing through. Add 40ml of NaCl solution with a concentration of 3.2mol / L in the anode zone as the anolyte, and add 120ml of saturated NaHCO with a concentration of 1.14mol / L in the cathode zone 3 The solution is used as the electrolyte at the same time as the reaction raw material, after loading 400mA direct current. A gas diffusion electrode is used as the anode electrode 1, and a metal nickel electrode is used as the cathode electrode 3. Use a needle syringe to draw 0.5ml of anolyte every 10-20 minutes to determine the hydrogen ion concentration. When the hydrogen ion concentration in the solution is higher than 3.168mol / L, take out the cathode and anolyte respectively, and the anolyte is at a concentration of 3.168 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com