Rotary activating furnace

An activation furnace and rotary technology, applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems of low production efficiency of activated carbon, insufficient contact between steam and air distribution and raw materials, and insufficient combustion of raw materials, etc., to achieve The structure is simple, the production efficiency is improved, and the effect of ensuring uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

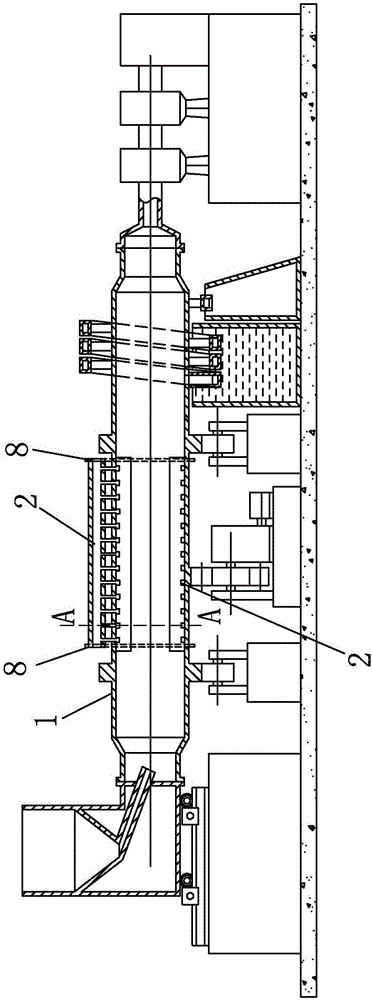

[0026] Such as figure 1 As shown, the rotary activation furnace includes a furnace body 1, a furnace head arranged on the left side of the furnace body and connected with the furnace body. 1 connected storage hopper, the furnace body 1 is inclined downward from left to right, the right side of the furnace body 1 is connected with the waste heat boiler through the first pipe, an operating platform is provided under the furnace head, and the outer wall of the furnace body 1 is connected with the furnace body 1 An integrated rotating ring gear, and a power operating platform is arranged under the rotating ring gear. The gears on the power operating table mesh with the rotating ring gear. There is a left supporting wheel belt integrated with the furnace body 1 above, two sets of rollers are arranged on the left supporting seat, the left supporting wheel belt is in contact with the two sets of rollers, and a through hole is provided on the right bottom wall of the furnace body 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com