Adjusting device for powder transportation

A technology of adjusting device and material conveying, which is applied in the directions of transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problem of inability to adjust the material speed, and achieve the effect of improving efficiency, simple device structure, and automatically adjusting the cutting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

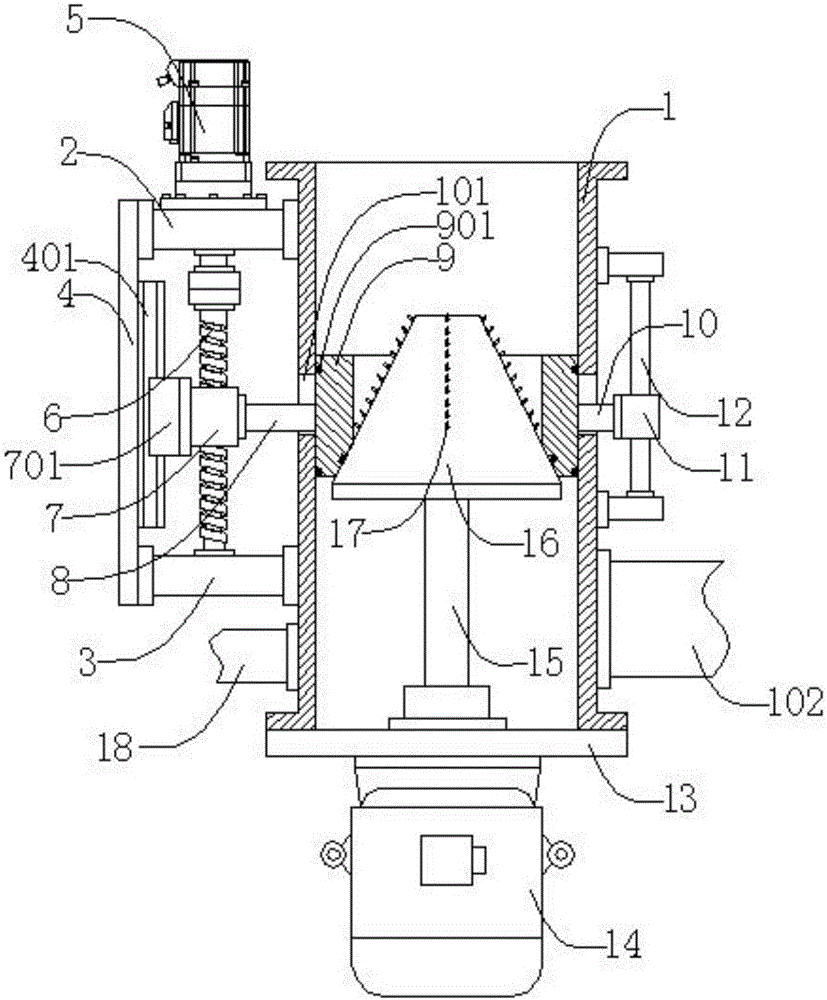

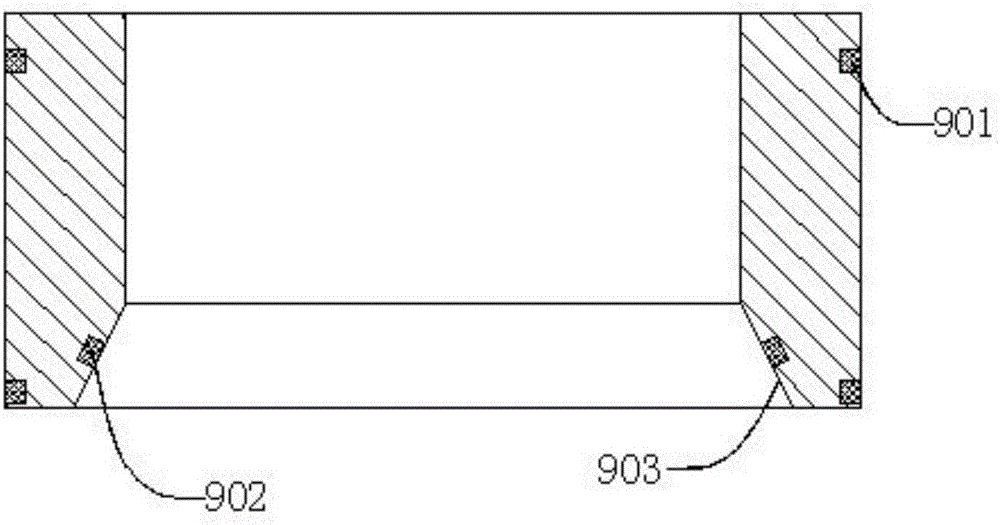

[0030] Such as figure 1 , figure 2As shown, a powder feeding adjustment device includes a pipe body 1, an upper support seat 2, a lower support seat 3, a support plate 4, a servo motor 5, a lead screw 6, a feed nut 7, a left connecting rod 8, a slide Cover 9, right connecting rod 10, guide block 11, guide rod 12, blocking plate 13, motor 14, rotating shaft 15, conical blanking head 16, several rake nails 17, air duct 18, the upper support seat 2 Located at the upper left side of the pipe body 1, the upper support seat 2 is threadedly connected with the pipe body 1, and the lower support seat 3 is located at the left lower end of the pipe body 1, and the lower support seat 3 is threadedly connected with the pipe body 1 , the support plate 4 is located on the left side of the upper support base 2 and on the left side of the lower support base 3, the support plate 4 is threaded with the upper support base 2 and connected with the lower support base 3, and the servo motor 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com