Multidirectional double-drive rail guide vehicle

A dual-drive shuttle and wheel technology, which is applied in the field of shuttles, can solve the problems of unable to drive the shuttle to run normally, unable to adapt to complex working environments, and not having steering functions, so as to increase the utilization rate of warehouse space and improve the warehouse space. Utilization, the effect of increasing the diversity of layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

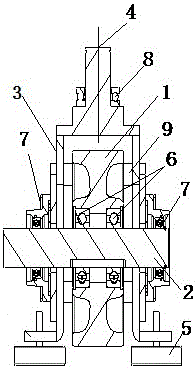

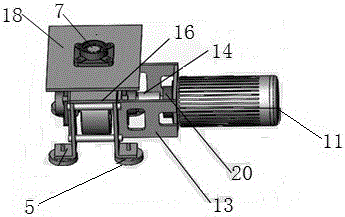

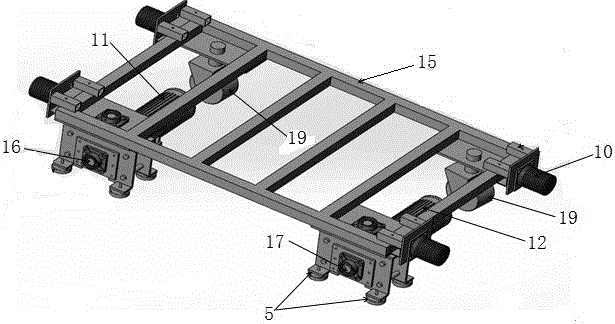

[0013] The main drive system comprises a main motor 11, a support 13, an electromagnetic brake 20, a shaft coupling 14, a front driving wheel 16, a mounting plate 18 and a bearing with seat 7; The main motor 11 housing is fixed, and the other end of the bracket 13 is fastened on the front driving wheel 16; the main motor 11 is fixed by the bracket 13, and the output shaft of the main motor 11 is connected with the shaft of the front driving wheel 16 through a coupling 14; the electromagnetic brake 20 is installed on the output shaft of the main motor 11; the mounting plate 18 is a flat plate with a mounting hole in the center, and the mounting plate 18 is horizontally installed on the top of the front driving wheel 16, and the mounting plate 18 and the car body 15 are welded and fixed; the front driving wheel 16 Including wheel 1 and wheel axle 2, wheel side plate 3 and top plate, guide rail stop wheel 5 and stop bar 9; wheel side plate 3 is two flat plates located on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com