Method for making wrong cigarette packet return to warehouse automatically

A cigarette pack and error technology, applied in the field of automatic return of wrong cigarette packs, can solve problems such as time constraints, increased difficulty of cigarette packs, and increased manual operation, so as to ensure uninterrupted production, reduce manual intervention, and speed up timely replenishment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

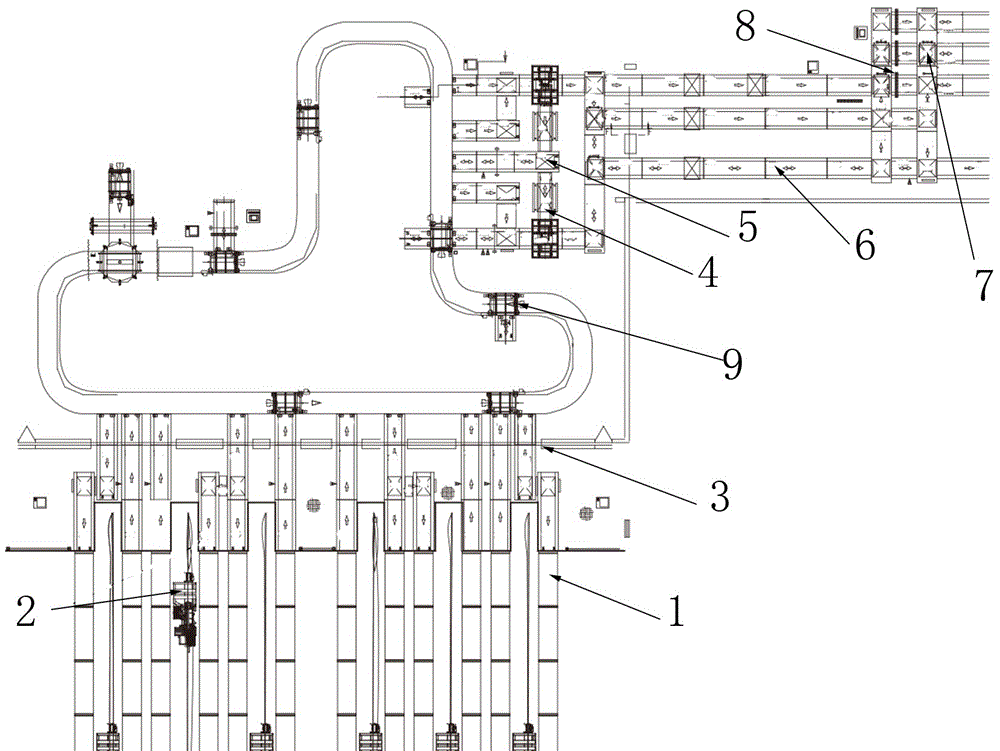

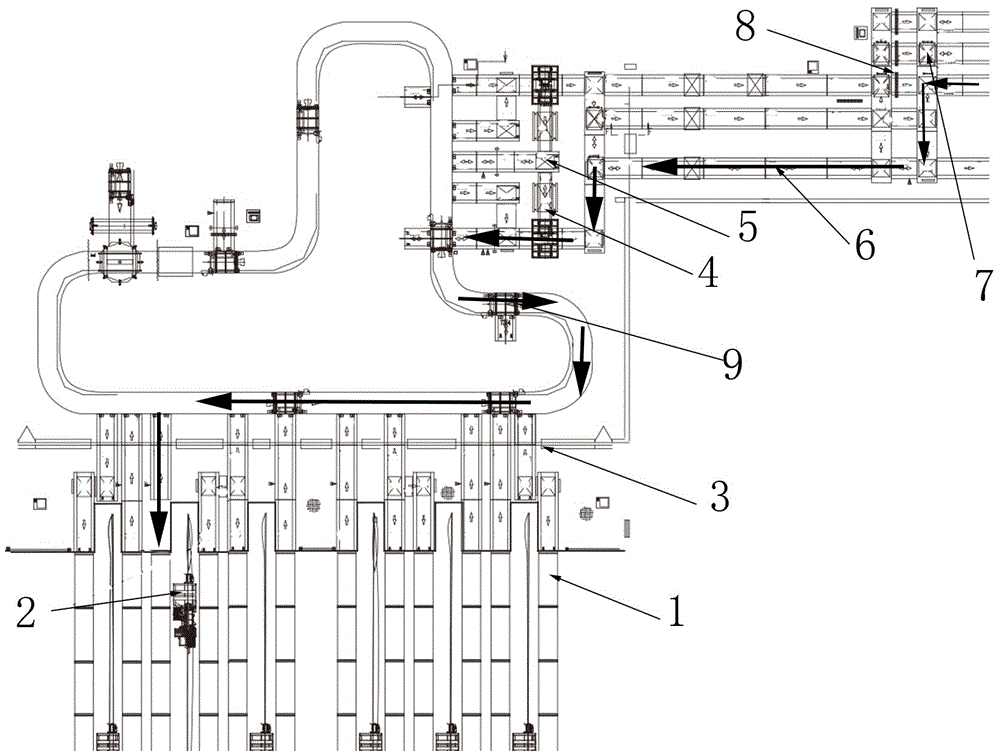

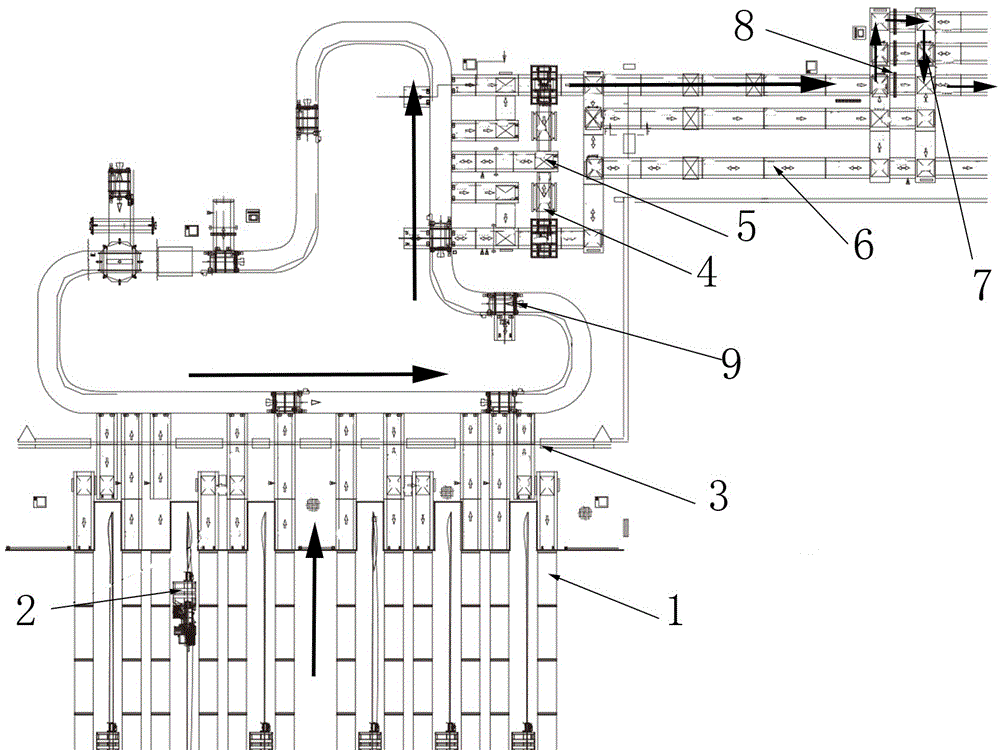

[0019] See attached picture. The elevated warehouse system involved in the method for automatically returning wrong cigarette packs to the warehouse described in this embodiment includes an elevated warehouse 1, a stacker 2, an inbound and outbound conveyance system 3, a clamping machine 4, a yarding machine 5, and a cigarette pack return conveying line 6 , Cigarette package barcode scanner 7, LED display 8, EMS trolley system 9, electronic control system, warehouse management system WMS and enterprise production information management system MES;

[0020] Elevated warehouse 1 is used to store cigarette packs and tray groups with trays; stacker 2 is used to pick and place cigarette packs and tray groups; inbound and outbound conveying system 3 is used to transfer inbound and outbound cigarette packs and tray sets; clamping machine 4 It is used for separating and stacking cigarette packs and trays; the code sorting machine 5 is used for pallet separation and stacking; the cigar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com