Batch packaging release device for box-packed cosmetics

A technology of batch packaging and cosmetics, applied in the field of boxed cosmetics batch packaging equipment, can solve the problems of wasting human resources, increasing the company's production costs, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

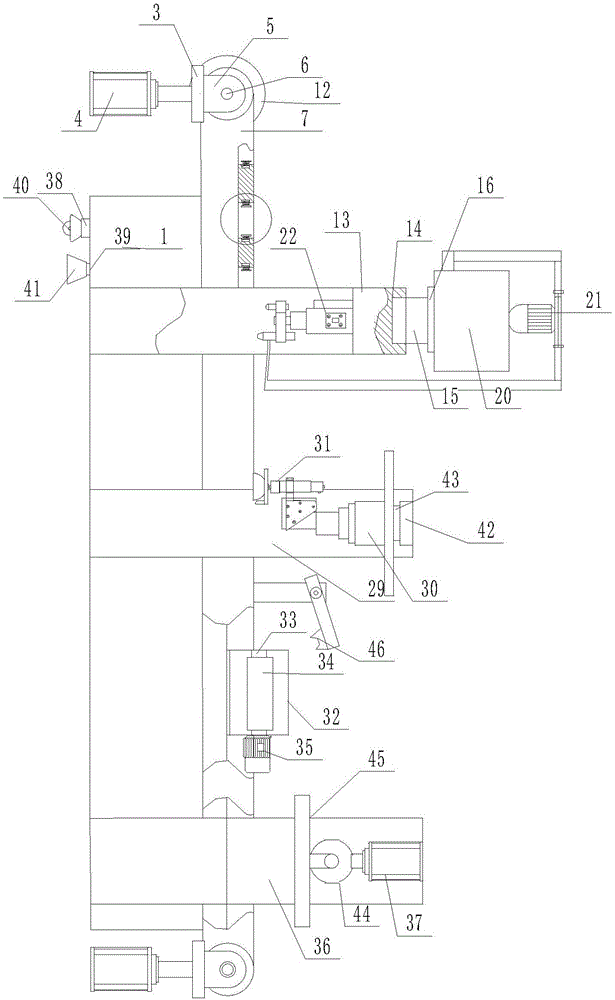

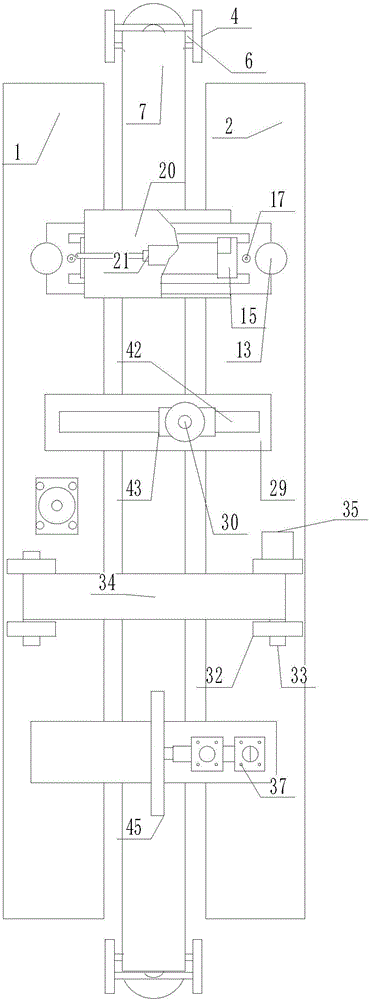

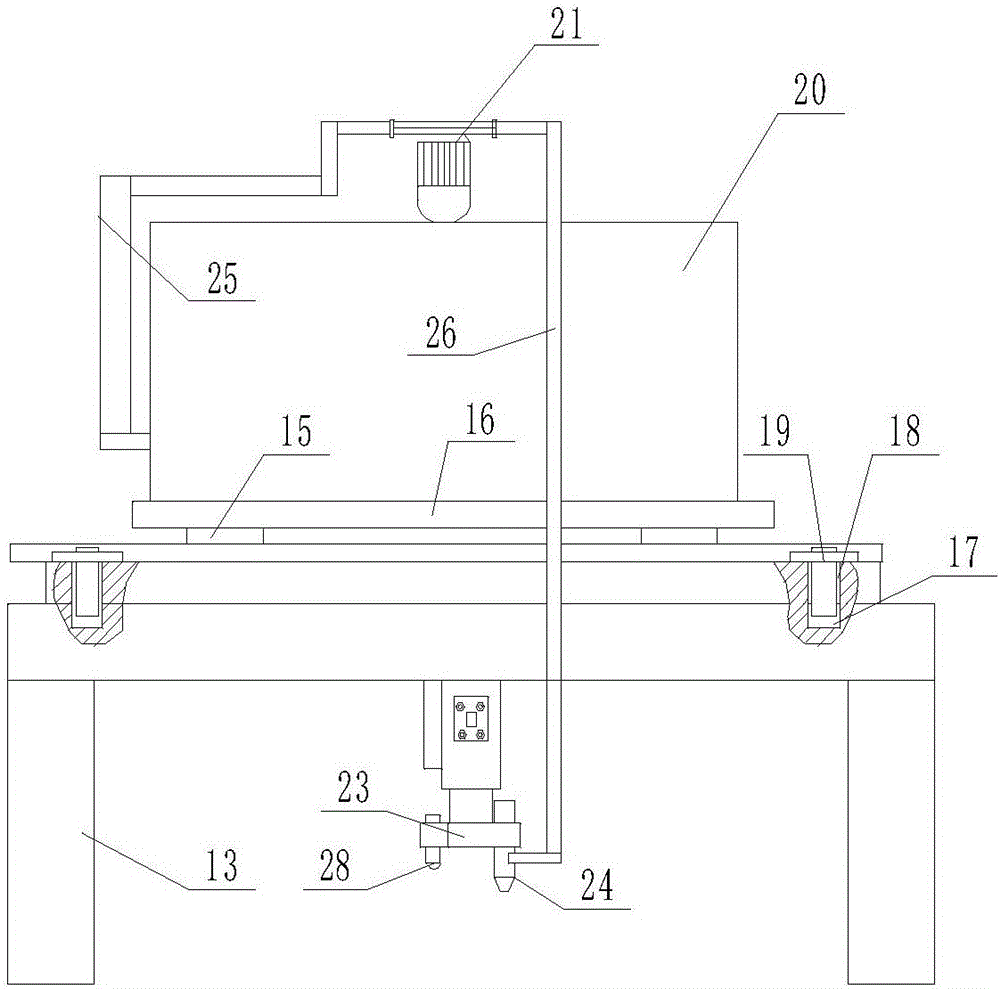

[0025] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-7As shown, a box-packed cosmetics batch packaging and exit equipment includes No. 1 body (1) and No. 2 body (2), and the lower surfaces of the No. 1 body (1) and No. 2 body (2) are fixed with moving mechanisms , the No. 1 body (1) and the No. 2 body (2) are both hollow structures inside; and the outside is a rectangular structure, and a conveying mechanism is set between the No. 1 body (1) and No. 2 body (2), so The No. 1 body (1) and the No. 2 body (2); and the raw material pouring mechanism, sealing mechanism and box cover conveying mechanism are arranged directly above the conveying mechanism, and the label printing mechanism is fixed on the No. 1 body (1) , the conveying mechanism is composed of a pair of conveying seats (3) installed on the ground between the No. The shaft frame (5) installed on the lifting cylinder (4), the conveying shaft (6) inserted on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com