Automobile tailboard

A technology for tailgates and substrates, which is applied in the direction of motor vehicles, loading and unloading vehicles, and vehicles used for freight transportation. It can solve problems such as the inability to achieve lightweight tailgates, insufficient strength of tailgates, and limited load-carrying quality. To achieve the effect of lightweight design, enhanced strength and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

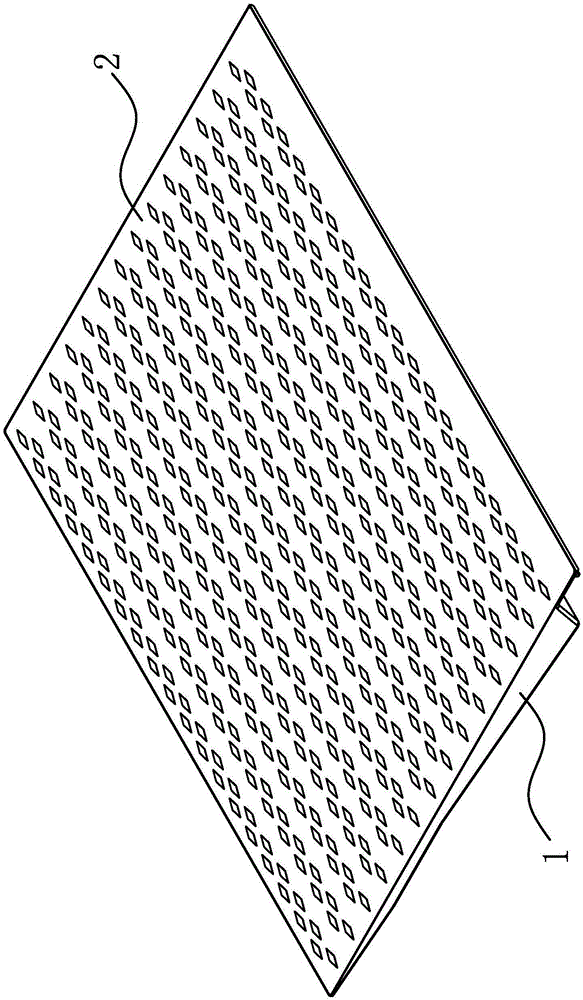

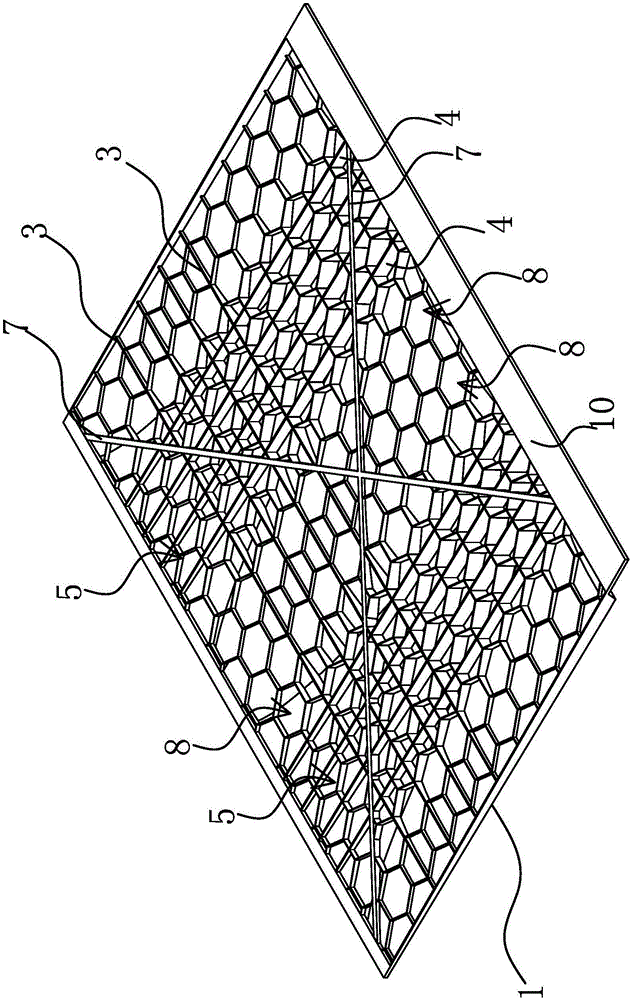

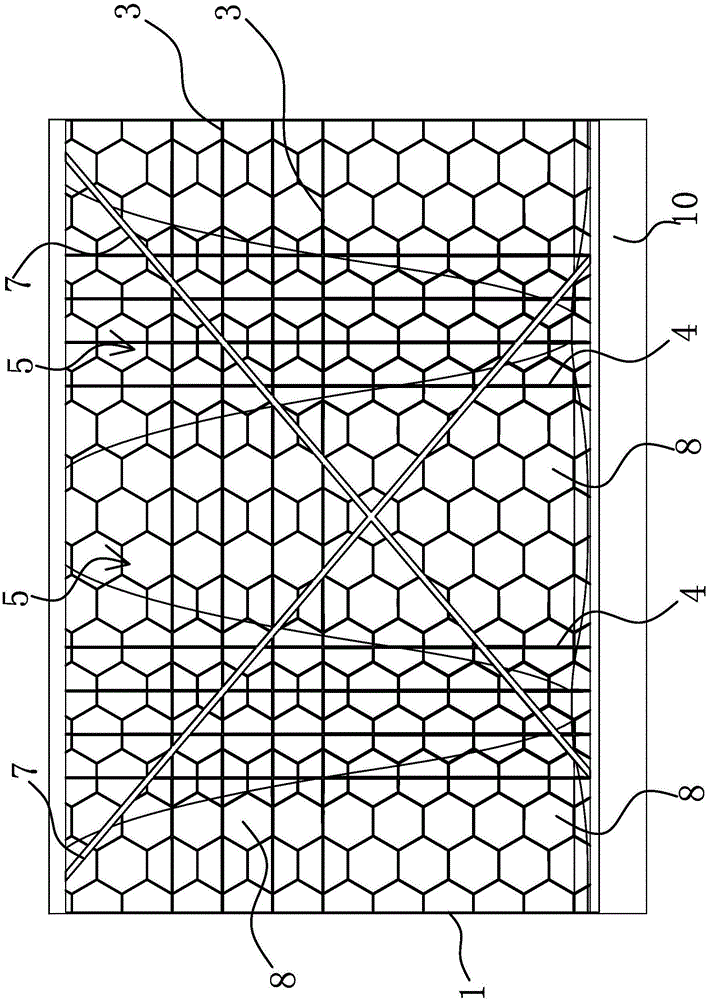

[0035] Such as Figure 1 to Figure 5 As shown, an automobile tailgate includes a substrate 1 and a panel 2. The panel 2 covers the substrate 1 and is fixedly connected to the substrate 1. The upper surface of the panel 2 has more textured protrusions or is hollowed out to increase the surface area. Friction prevents slipping. The upper surface of the base plate 1 is integrally formed with a number of reinforced horizontal plates 3 and a number of reinforced vertical plates 4, the reinforced horizontal plates 3 and the reinforced vertical plates 4 can respectively ensure the compression and bending resistance of the base plate 1 in the longitudinal and transverse directions, and the present invention The reinforced horizontal plate 3 and the reinforced vertical plate 4 are integrally formed with the base plate 1, and both the reinforced horizontal plate 3 and the reinforced vertical plate 4 are vertically arranged with the panel 2. By setting perpendicular to the panel 2, it c...

Embodiment 2

[0042] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 6 As shown, the upper surface of the tailgate of this automobile is not provided with a honeycomb structure, but each reinforced horizontal plate 3 and reinforced longitudinal plate 4 are pierced with a number of reinforcing ribs 9 and the reinforcing ribs 9 are connected with the reinforced horizontal plate 3 and the reinforced longitudinal plate 4 Formed in one piece, the reinforcing ribs 9 are evenly arranged along the length direction of the reinforcing horizontal plate 3 or the reinforcing longitudinal plate 4 . Specifically, before the substrate 1 is casted, the reinforcing ribs 9 are pulled at both ends of the mold by a tool, and then the reinforcing ribs 9 are fixed together in the reinforcing horizontal plate 3 and the reinforcing vertical plate 4 after the substrate 1 is cast. , when the molding is completed, the upper and lower molds ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com