Low-speed jitter control method and device for blade electric vehicle, and blade electric vehicle

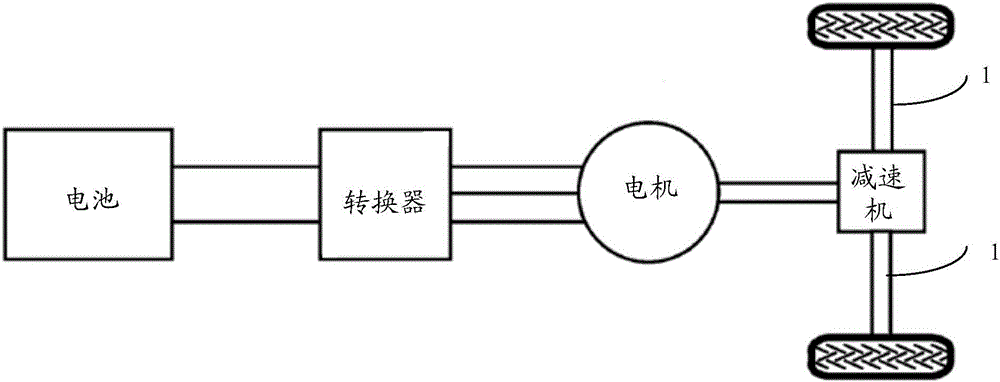

A pure electric vehicle, low-speed technology, applied in the field of low-speed jitter control, pure electric vehicles, to reduce negative effects, improve riding experience, and solve low-frequency jitter problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

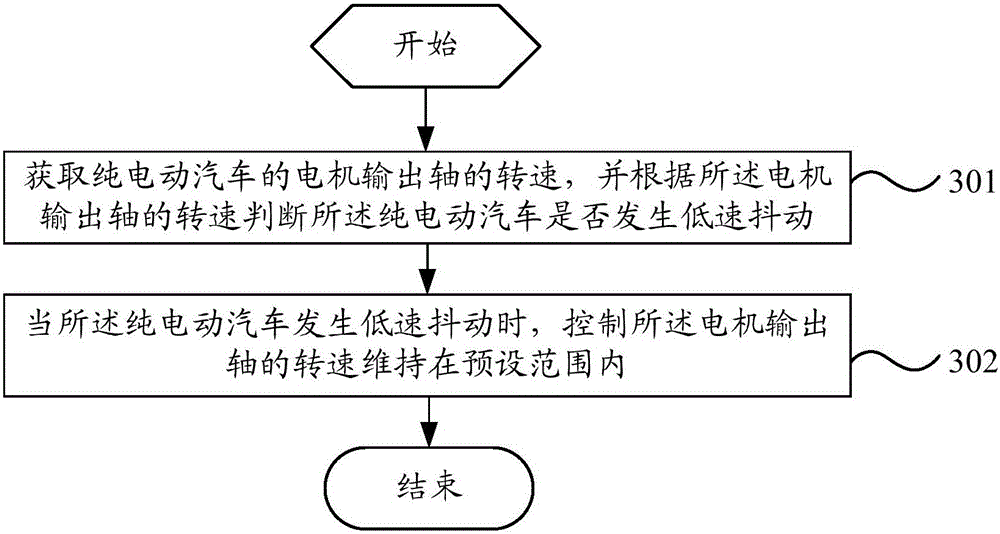

[0050] Embodiments of the present invention provide a low-speed vibration control method for pure electric vehicles, such as image 3 As shown, the method includes:

[0051] Step 301: Obtain the rotation speed of the motor output shaft of the pure electric vehicle, and judge whether the pure electric vehicle has low-speed vibration according to the rotation speed of the motor output shaft.

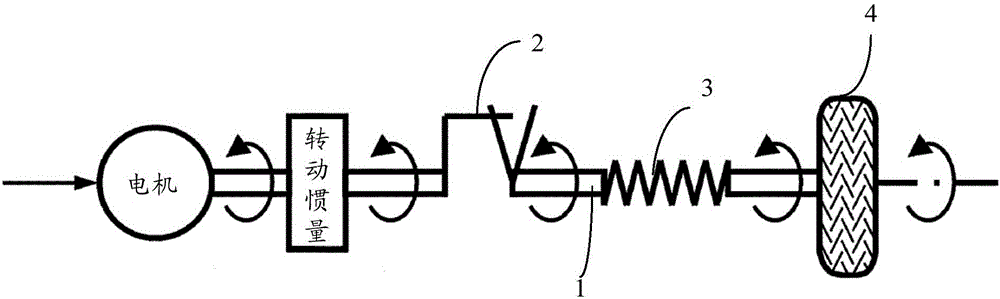

[0052] Among them, the lower the frequency of the motor of the pure electric vehicle, the lower the speed of the output shaft of the motor. Therefore, the low-speed dithering can also be called low-frequency dithering.

[0053] In addition, when the pure electric vehicle shakes at low speed, the speed of the output shaft of the motor jumps. Therefore, in the embodiment of the present invention, it is judged whether low-speed vibration occurs in the pure electric vehicle by monitoring the rotation speed of the output shaft of the motor in real time.

[0054] Further, step 301 includes: ...

no. 2 example

[0074] An embodiment of the present invention provides a low-speed jitter control device for a pure electric vehicle. Preferably, the low-speed jitter control device for a pure electric vehicle may specifically be a motor controller.

[0075] Such as Figure 4 As shown, the low-speed vibration control device 400 of the pure electric vehicle includes:

[0076] The shake judging module 401 is used to obtain the speed of the motor output shaft of the pure electric vehicle, and judge whether the pure electric car has low-speed shake according to the speed of the motor output shaft;

[0077] The vibration control module 402 is configured to control the rotation speed of the output shaft of the motor to maintain within a preset range when the pure electric vehicle vibrates at a low speed.

[0078] Preferably, as Figure 5 As shown, the shake judgment module 401 includes:

[0079] The rotation speed acquisition unit 4011 is used to acquire the rotation speed of the motor output sh...

no. 3 example

[0094] An embodiment of the present invention provides a pure electric vehicle, including the above-mentioned low-speed jitter control device for a pure electric vehicle.

[0095] Therefore, in the pure electric vehicle of the embodiment of the present invention, by monitoring the speed of the motor output shaft in real time to determine whether the pure electric vehicle has low-speed jitter, and then control the speed of the motor output shaft to remain within the preset range when low-speed jitter occurs, that is, to adjust The speed of the output shaft of the motor eliminates its jumps, thereby solving the low-frequency vibration problem of pure electric vehicles, reducing the negative impact of low-speed vibration of the whole vehicle, and improving the riding experience of drivers and passengers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com