An automobile air outlet blade transmission mechanism

A transmission mechanism and air outlet technology, which is applied in the field of auto parts, can solve the problems of complex structure of the transmission mechanism and inconvenient maintenance, and achieve the effect of good transmission effect, prevention of changing direction, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

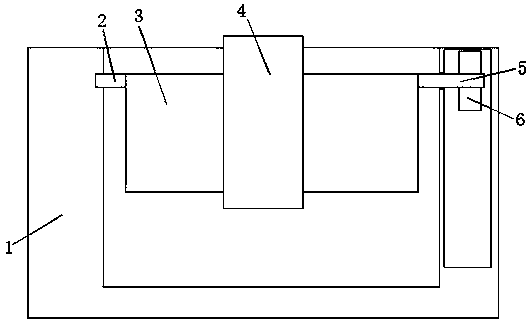

[0020] Embodiment: the first blade 3 on the device is movably installed in the automobile air outlet assembly housing 1 through the first rotating shaft 2 and the second rotating shaft 5, and the first rotating shaft 2 and the second rotating shaft 5 are connected with the automobile air outlet assembly respectively. The casing 1 is movably connected with the partition plate, the gear 6, the fixed column 11 and the elastic piece 12 are all located on the side of the partition plate away from the first blade 3, the adjacent first blades 3 are in line with each other, and the adjacent gears 6 Mesh with each other, the second blade 9 is movably installed in the automobile air outlet assembly housing 1 through the third rotating shaft 10, and the guide block 4 is held to swing and rotate up and down, and the guide block 4 drives one of the first blades 3 to swing and rotate up and down. The blade 3 drives a gear 6 to rotate through the second rotating shaft 5, and the gear 6 drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com