Butt joint structure and fan with butt joint structure

A technology of docking direction and connecting parts, which is applied in the direction of connecting components, rods, mechanical equipment, etc., can solve the problems of complicated disassembly and assembly, loose threads of two pipe fittings, etc., and achieve simple and fast installation, good sliding joint guiding effect, and guarantee The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

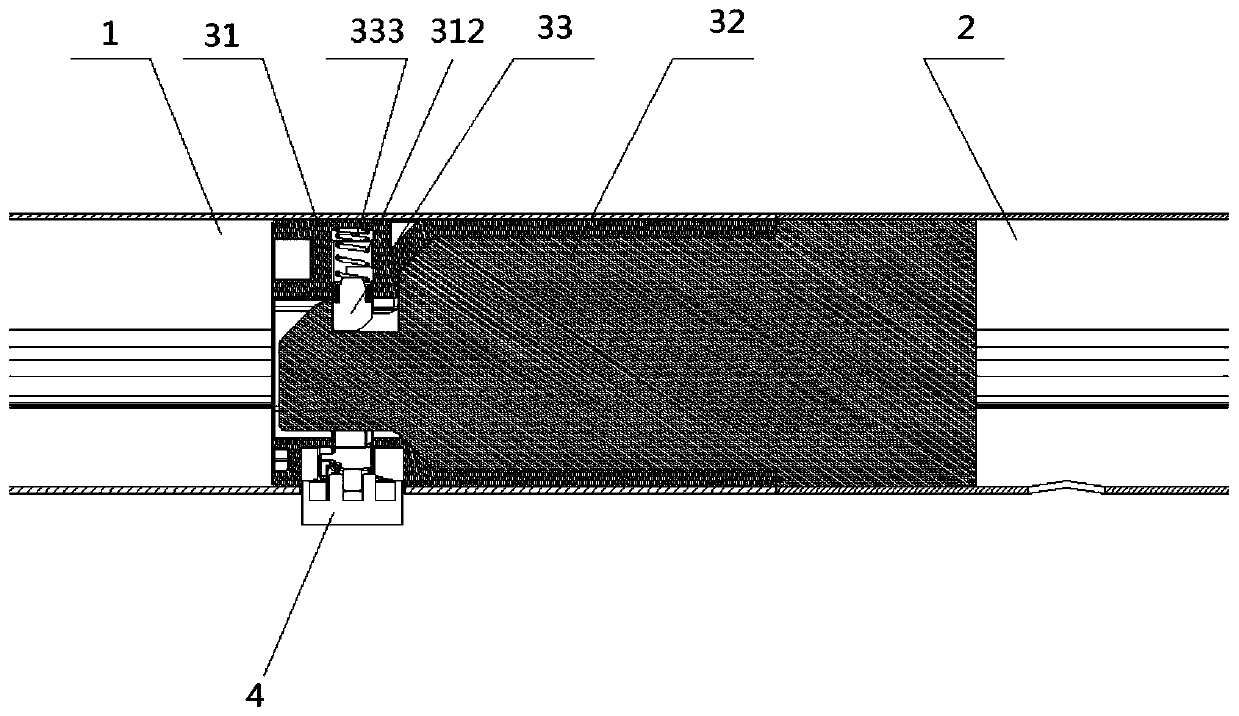

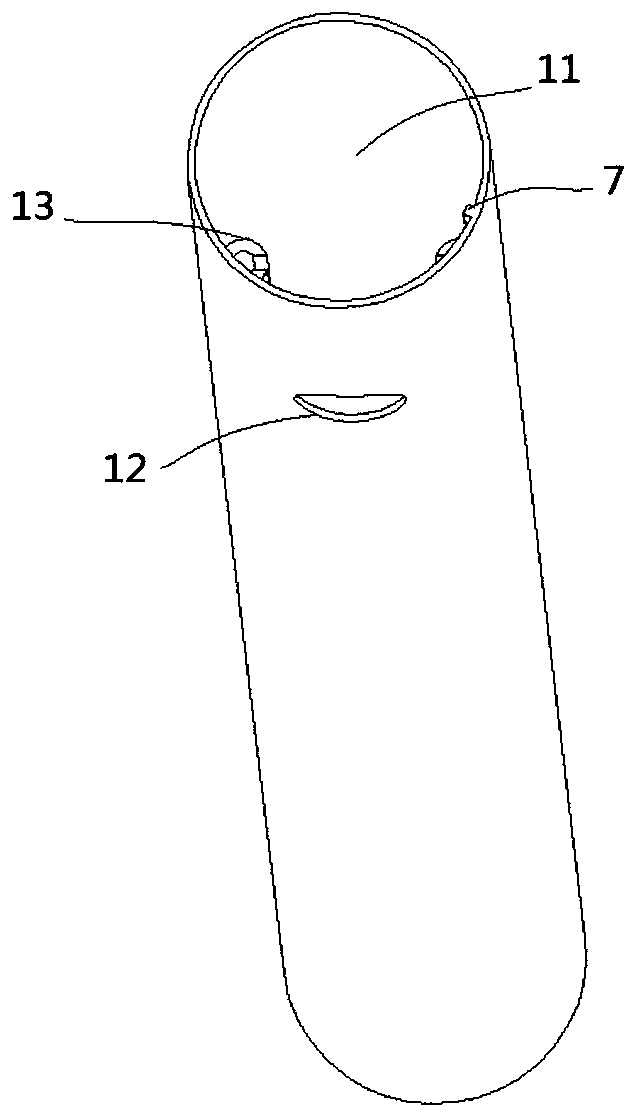

[0056] Figure 1 to Figure 10 As shown, it is a docking structure provided by this embodiment, including a first connecting piece 1 and a second connecting piece 2, and first grooves 11 are respectively arranged on the butting surfaces of the first connecting piece 1 and the second connecting piece 2 and the second groove 21; and the docking assembly 3 arranged on the first groove 11 and the second groove 21, the docking assembly 3 includes: a female joint 31, which is arranged in the first groove 11; a male joint 32, which is set On the second groove 21, it has a chuck 321, which protrudes from the second groove 21; a locking assembly 33, a via hole 311 is provided on the peripheral surface of the female joint 31, and is locked along a direction perpendicular to the docking direction. The buckle component 33 is movably arranged in the female joint 31 at the through hole 311. After being docked in place, the chuck head 321 is clamped on the lock component 33; the button 4 is s...

Embodiment 2

[0079] This embodiment provides a fan, specifically a floor fan, which includes the docking structure described in Embodiment 1 above, and has all its technical advantages, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com