Lower swinging arm

A hem and body technology, applied to the cantilever mounted on the pivot, suspension, transportation and packaging, etc., can solve the problems of complex structure of the lower arm, low strength of the lower arm, poor stability and comfort of the bushing, etc., to achieve The effect of driving comfort and steering stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

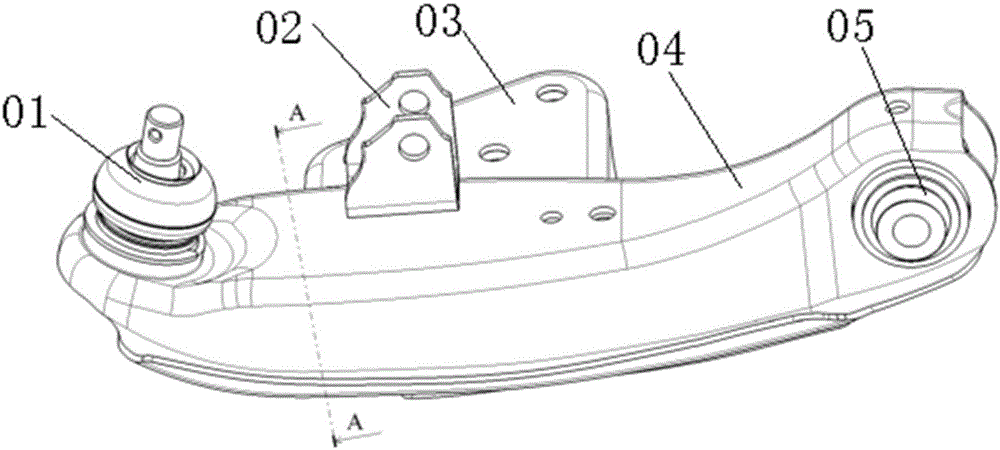

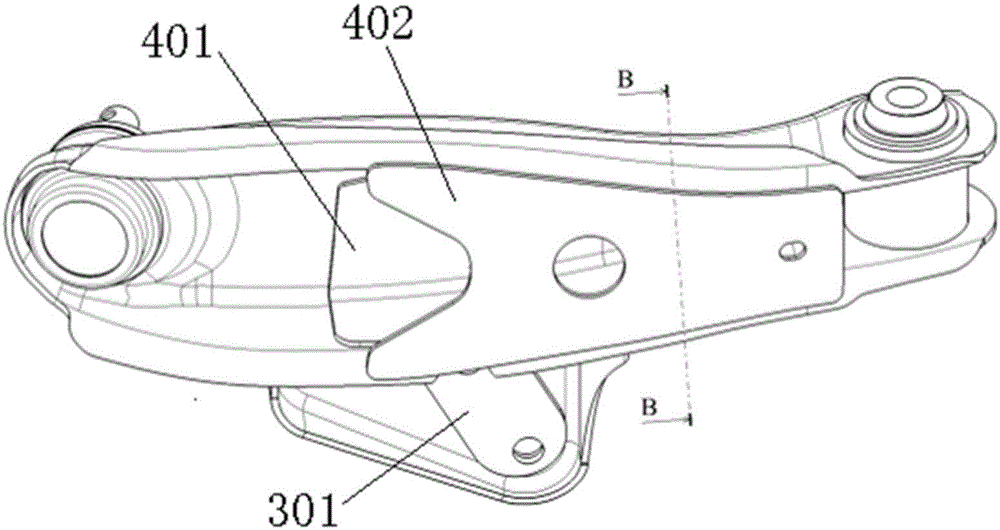

[0036] This application provides a lower swing arm, such as Figure 5 to Figure 13 As shown, it includes a yoke-type lower swing arm body 1, a ball pin 2 is arranged on one side of the lower swing arm body, a shock absorber mounting seat 3 is arranged on the lower swing arm body, and a front end of the other side of the lower swing arm body is arranged. There is a first bush 4, and a second bush 5 is provided at the rear end.

[0037] The main body of the lower swing arm in this application is formed by welding two pieces of sheet metal after stamping. In this embodiment, the sections of the lower swing arm body are all approximately h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com