Double eccentric wheel type steel seal dialing device

An eccentric wheel type, dial device technology, applied in printing, stamping and other directions, can solve the problems of unsatisfactory effect, affecting the production and operation efficiency of equipment, narrow adjustment range, etc., to achieve the accuracy of printing positioning, clear handwriting, and large range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

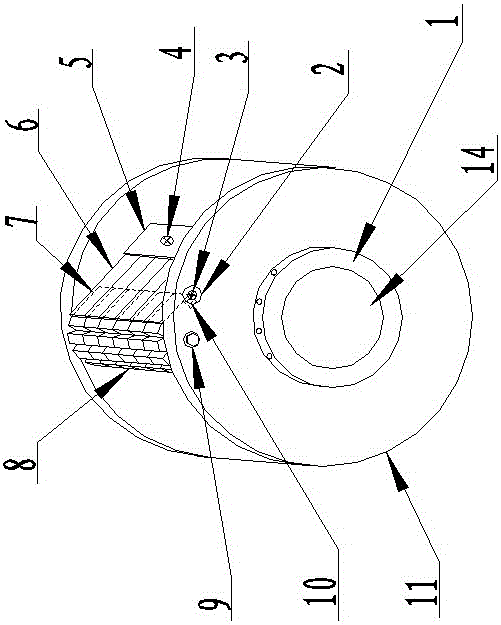

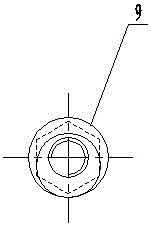

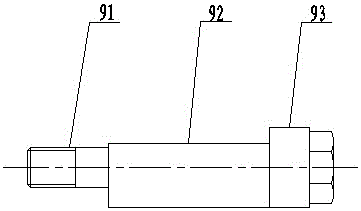

[0021] Such as Figure 1 to Figure 7 As shown, a double eccentric wheel type stamped dialing device of the present invention includes a stamped seat 11 and a steel number wheel 8, a steel number wheel installation cavity is reserved in the stamped seat 11, and the steel number wheel 8 is installed in the steel number wheel installation cavity Inside, it also includes an eccentric shaft 9 arranged axially along the stamp seat 8, the eccentric shaft is composed of a front mounting shaft section 91, a middle eccentric shaft section 92 and a rear mounting shaft section 93, and the front mounting shaft section 91 and the rear mounting shaft section 93 It is set coaxially, and the front mounting shaft section 91 and the rear mounting shaft section 93 are detachably and fixedly connected with the stamp seat 11 respectively, and the steel number wheel 8 is sleeved on the middle eccentric shaft section 92 and rotatably matched with it.

[0022] The steel number wheel 8 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com