Undrawn polyethylene film and preparation method thereof

A polyethylene film, high pressure polyethylene technology, applied in chemical instruments and methods, flexible coverings, types of packaging items, etc., can solve the problems of unfavorable food safety, fragile heat sealing ports, insufficient strength, etc., to avoid puncture Wear or scratches, reduced air permeability, good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

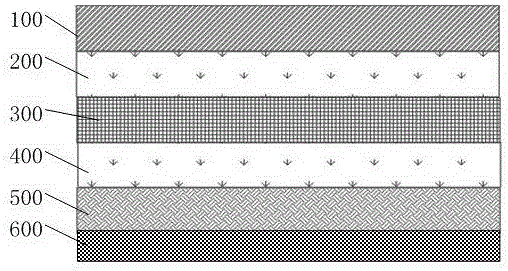

[0031]In the unstretched polyethylene film, the thickness percentages of the heat-sealing layer 100, the first intermediate layer 200, the auxiliary layer 300, the second intermediate layer 400, and the corona layer 500 are respectively: 20%, 17.5% , 20%, 17.5%, 25%. Specifically, the heat-sealing layer 100 includes components by mass percentage: 20% high-pressure polyethylene, 30% linear polyethylene, 48% metallocene polyethylene, and 2% opening agent; the first intermediate layer 200 and the second The mass percentages of the components included in the second middle layer 400 are: 20% high pressure polyethylene, 30% low pressure polyethylene, 50% metallocene polyethylene; the mass percentages of the components included in the auxiliary layer 300 are: 40% high pressure polyethylene, 40% linear polyethylene 50% ethylene, 10% low-pressure polyethylene; the corona layer 500 includes components by mass percentage: 24% high-pressure polyethylene, 50% linear polyethylene, 25.8% met...

Embodiment 2

[0033] In the unstretched polyethylene film, the thickness percentages of each layer among the heat-sealing layer 100, the first intermediate layer 200, the auxiliary layer 300, the second intermediate layer 400, and the corona layer 500 are respectively: 20%, 20%, 20%, 15%, 25%. Specifically, the heat-sealing layer 100 includes the following mass percentages: 33% high-pressure polyethylene, 33% linear polyethylene, 33% metallocene polyethylene, and 1% anti-blocking agent; the first intermediate layer 200 and the second The mass percentages of the components included in the second middle layer 400 are: high pressure polyethylene 33%, low pressure polyethylene 33%, metallocene polyethylene 33%; the components mass percentages of the auxiliary layer 300 are: high pressure polyethylene 45%, linear polyethylene 50% ethylene, 5% low-pressure polyethylene; the corona layer 500 includes 25.9% high-pressure polyethylene, 50% linear polyethylene, 24% metallocene polyethylene and 0.1% t...

Embodiment 3

[0035] In the unstretched polyethylene film, the thickness percentages of each layer among the heat-sealing layer 100, the first intermediate layer 200, the auxiliary layer 300, the second intermediate layer 400, and the corona layer 500 are respectively: 25%, 15%, 20%, 15%, 25%. Specifically, the heat-sealing layer 100 includes the following mass percentages: 20% high-pressure polyethylene, 50% linear polyethylene, 25% metallocene polyethylene, and 5% anti-blocking agent; the first intermediate layer 200 and the second The mass percentage of components included in the second middle layer 400 is: 20% high pressure polyethylene, 50% low pressure polyethylene, 30% metallocene polyethylene; the mass percentage of components included in the auxiliary layer 300 is: 40% high pressure polyethylene, 40% linear polyethylene 50% ethylene, 10% low-pressure polyethylene; the corona layer 500 includes 30% high-pressure polyethylene, 39.82% linear polyethylene, 30% metallocene polyethylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com