Reversible thermochromatic film based on graphene electrothermal driving, preparation and application of reversible thermochromatic film

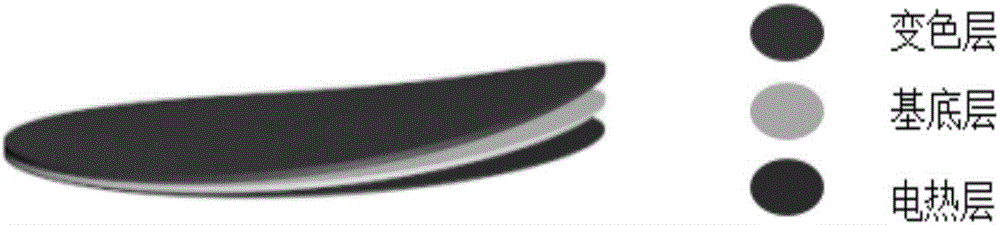

A thermochromic, electrothermally driven technology, applied in the direction of layered products, etc., to achieve the effects of fast discoloration time, mild reaction conditions, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of graphene oxide: Take 500 meshes and 3g flake graphite powder into a three-necked flask, add 69mL (95%-98%) concentrated sulfuric acid pre-frozen to 0°C. Slowly add 9 g of potassium permanganate in an ice-water bath, and then transfer to a 35° C. oil bath and keep stirring for 2 hours (the three-necked flask does not need to be stoppered, just leave it open). Set the heating temperature gradient to 35°C-50°C-65°C-80°C-98°C, and slowly add 138mL of ultrapure water dropwise during the heating process, and keep it at 98°C for 30min after the dropwise addition. During the addition of water, the color of the dispersion changed from black to dark green to reddish brown to golden yellow. Pour the solution in the flask into a preheated (about 30°C) solution (140mL ultrapure water + 2.5mL hydrogen peroxide) and cool naturally to room temperature. Use 250mL (1:10HCl, hydrochloric acid is 36-38%) to prepare a solution, and add it to the above-mentioned gr...

Embodiment 2

[0037] Reduced graphene oxide was prepared by the method reported in the literature (Advanced Materials, 2016, DOI: 10.1002 / adma.201603395.). Disperse 100 mg of graphene oxide powder into 100 mL of deionized water and sonicate with a cell disruptor for 0.5 h. Add 4 mL of ammonia water to the graphene oxide dispersion at one time, measure the pH of the mixture with a pH meter, and control it at 9-12. Weigh 0.1 mg of hydrazine hydrate solution and add it dropwise to the stirring graphite oxide solution, then heat the mixed liquid to 90° C. with a heating platform. Stir and seal the heat for 2 hours, that is, the solution turns from brown to black to complete the graphite oxide reduction process.

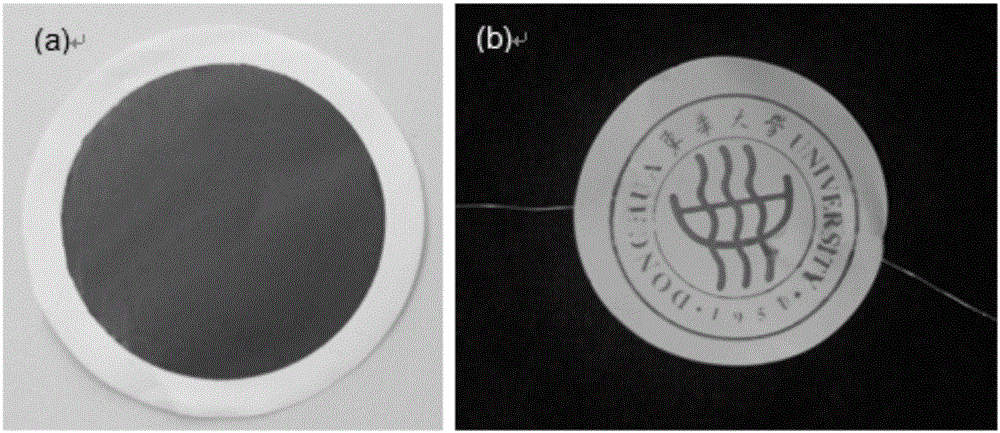

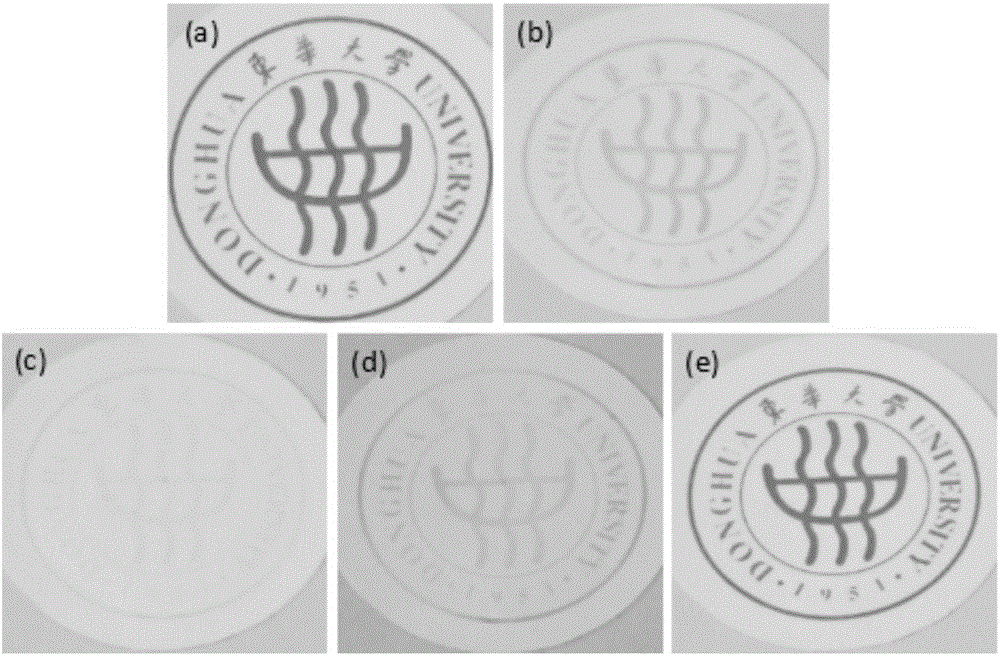

[0038] Take 10 mL of the reduced graphene oxide stock solution in a 150 mL beaker, and add 90 mL of ultrapure water to dilute to 100 mL to obtain a 0.01 mg / mL black translucent and uniformly dispersed reduced graphene oxide dispersion. Weigh 30 mL of the diluted reduced graphene oxid...

Embodiment 3

[0042] Reduced graphene oxide was prepared by the method reported in the literature (Advanced Materials, 2016, DOI: 10.1002 / adma.201603395.). Disperse 100 mg of graphene oxide powder into 100 mL of deionized water and sonicate with a cell disruptor for 0.5 h. Add 4 mL of ammonia water to the graphene oxide dispersion at one time, measure the pH of the mixture with a pH meter, and control it at 9-12. Weigh 0.1 mg of hydrazine hydrate solution and add it dropwise to the stirring graphite oxide solution, then heat the mixed liquid to 90° C. with a heating platform. Stir and seal the heat for 2 hours, that is, the solution turns from brown to black to complete the graphite oxide reduction process.

[0043] Take 10 mL of the reduced graphene oxide stock solution in a 150 mL beaker, and add 90 mL of ultrapure water to dilute to 100 mL to obtain a 0.01 mg / mL black translucent and uniformly dispersed reduced graphene oxide dispersion. Weigh 10 mL of the diluted reduced graphene oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com