Processing method of particle board

A processing method and particleboard technology, which are applied in the direction of wood processing appliances, manufacturing tools, pretreatment of molding materials, etc., can solve the problems of distortion, center deviation, slab damage, etc. of the upper and lower platens, and achieve the effect of easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

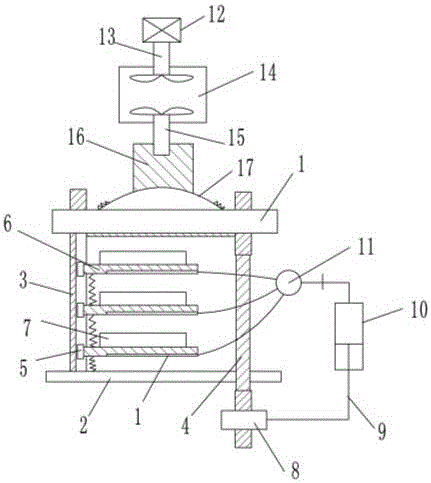

[0016] The reference signs in the drawings of the description include: upper platen 1, fixed plate 2, first support frame 3, second support frame 4, slider 5, heating plate 6, particle board 7, nut 8, push rod 9, air cylinder 10. Air pump 11, motor 12, first rotating shaft 13, water tank 14, second rotating shaft 15, lower pressing block 16, hydraulic block 17.

[0017] A kind of processing method of particle board in this scheme, comprises following process:

[0018] (1) Raw material preparation: remove some fresh corn stalks from leaves, slice the corn stalks obliquely through a chipper, and the thickness of the slices is 2mm.

[0019] (2) Sieving: Sieve the slices through a sieving machine to remove the epidermis, ridges and mud in the slices.

[0020] (3) Shavings: The sieved corn stalks are sliced by a roller flaker, and planed into flakes with an area of 5mm2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com