A full-automatic handbag punching and threading machine

A handbag, fully automatic technology, applied in container manufacturing machinery, paper/cardboard containers, packaging, etc., can solve the problems of poor product quality stability, bag deformation and damage, waste of manpower and material resources, etc. The effect of increasing the processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

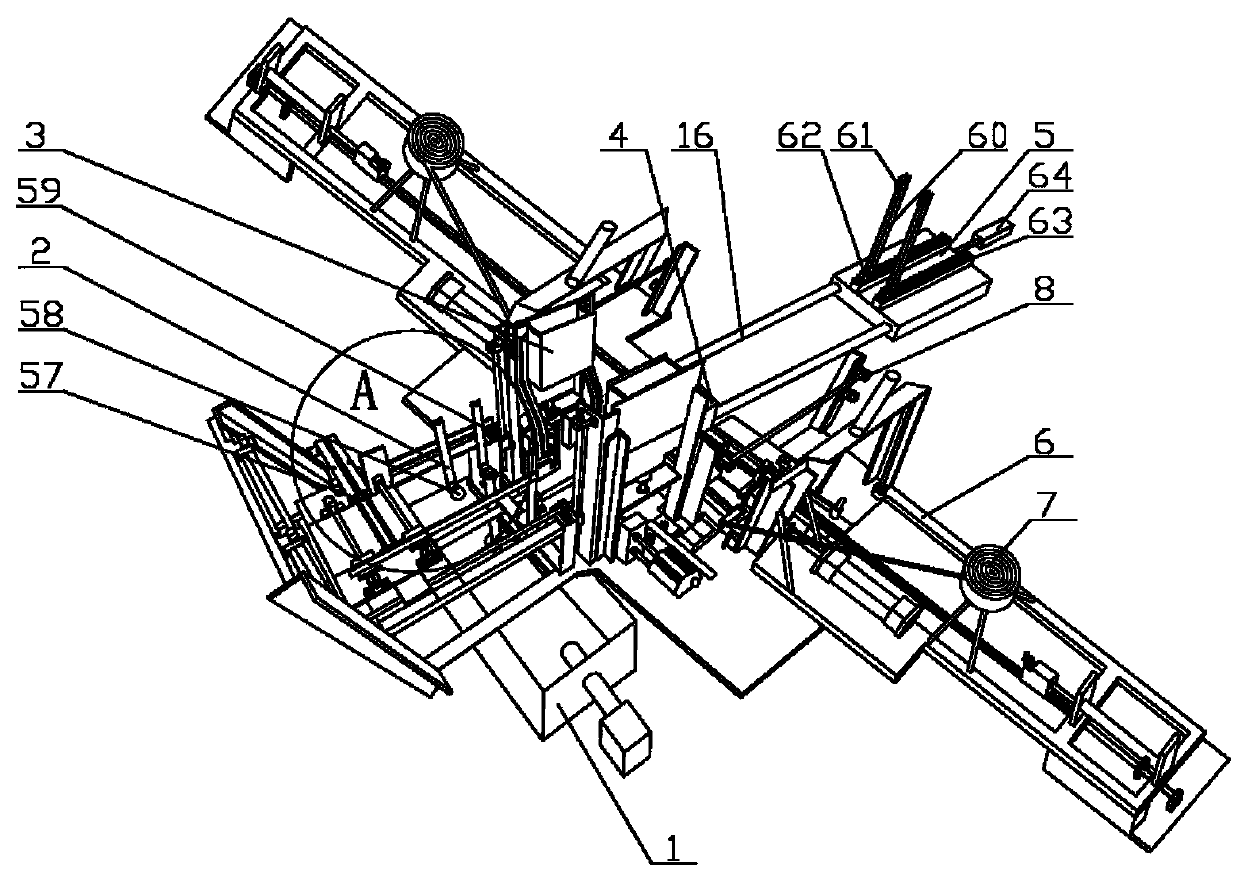

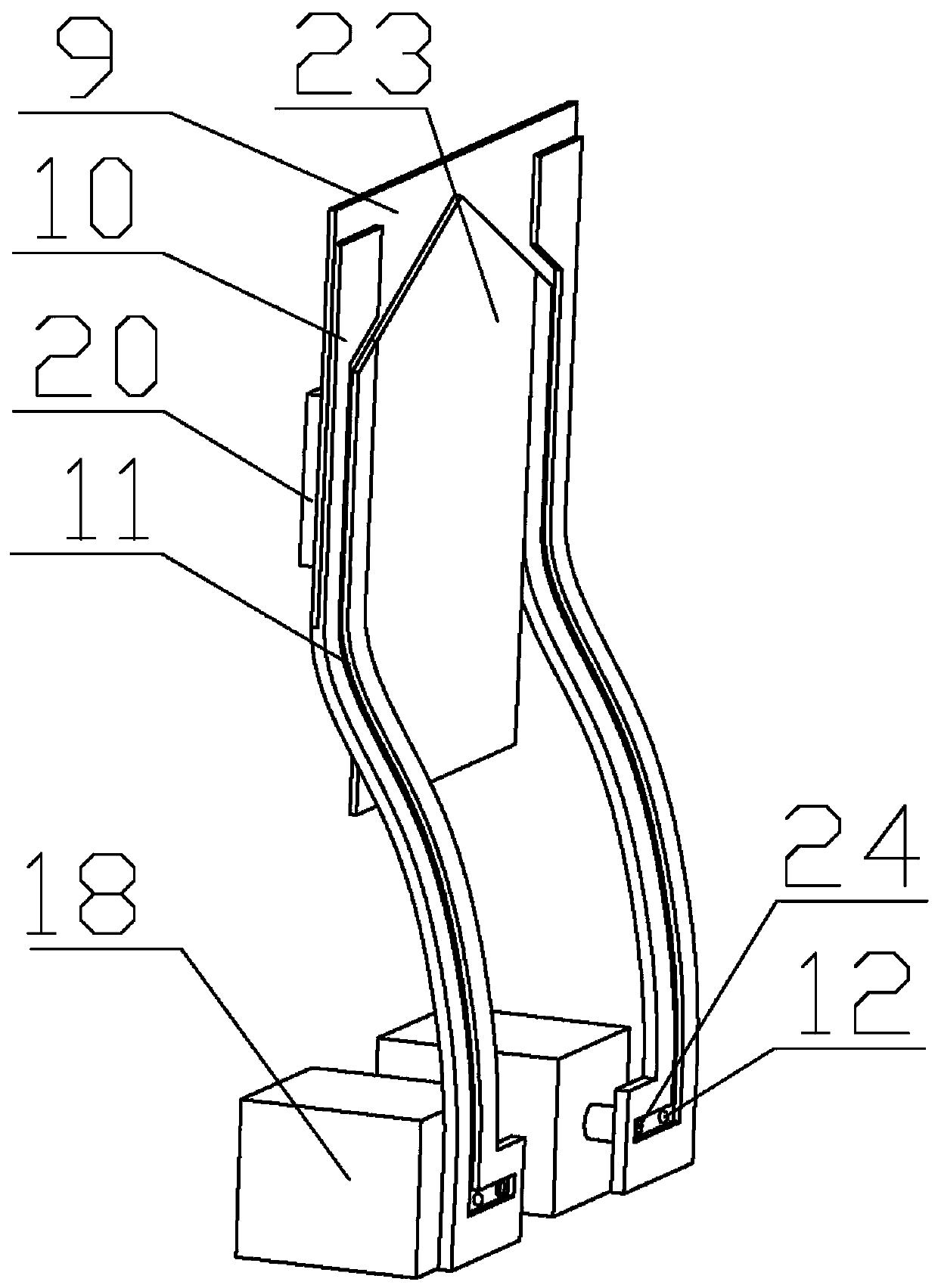

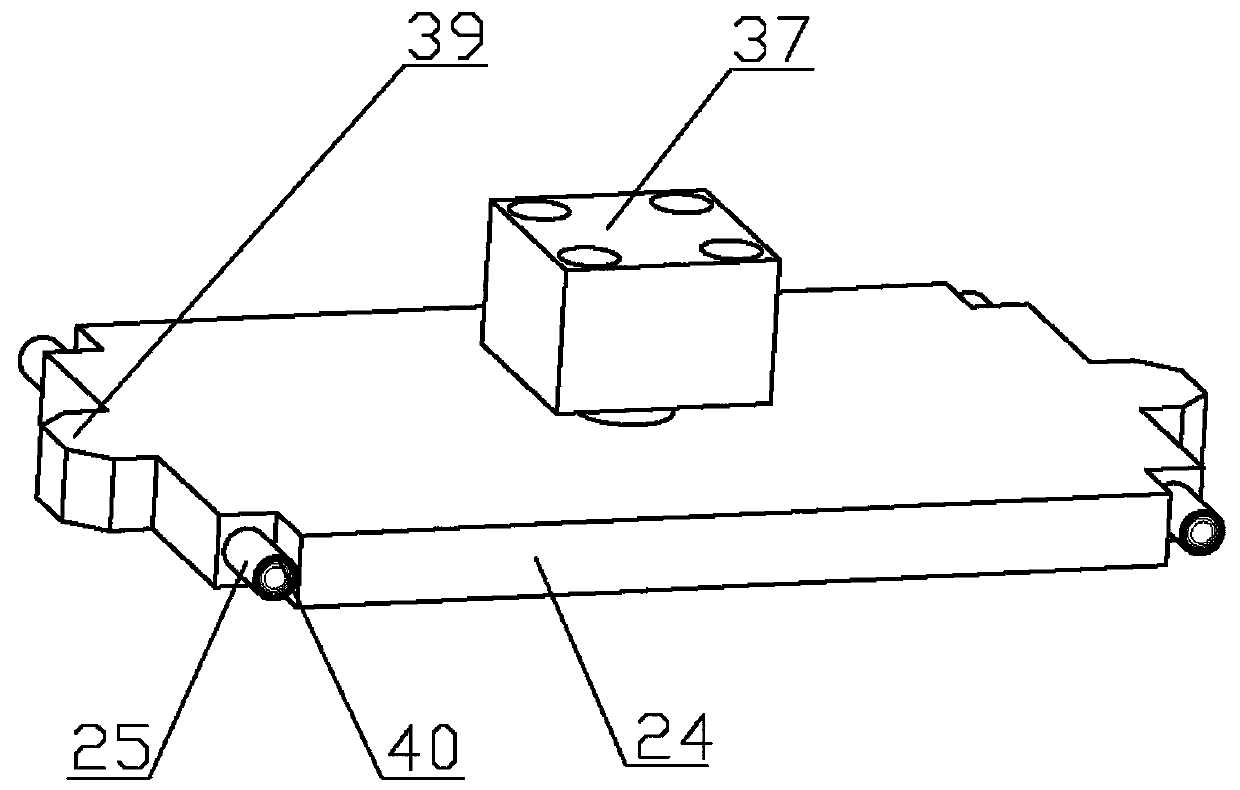

[0032] Such as Figure 1-14 As shown, the present invention includes a bag-up mechanism 1, two groups of bag-picking frames 2 arranged on both sides above the bag-loading mechanism 1, a bag-supporting mechanism 4 arranged in the middle of the two groups of bag-picking frames 2, symmetrically arranged on the bag-supporting mechanism Two groups of rope-threading mechanisms 6 on both sides of 4, the rope coiling frame 7 arranged above the two groups of rope-threading mechanisms 6, and the bag-removing mechanism 5 arranged on the side of the bag-supporting mechanism 4 away from the bag-loading mechanism 1; the rope-threading mechanism 6. There is a PLC control assembly on one side, and a packaging shell is also provided on the outside of the present invention, which is suitable for the processing of paper string handbags. The PLC control assembly is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com