T-shaped manipulator

A technology of manipulators and fuselages, applied in the direction of manipulators, program-controlled manipulators, claw arms, etc., can solve the problems of limiting the working range of manipulators, low production efficiency, and high manufacturing costs, so as to save working time, improve work efficiency, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

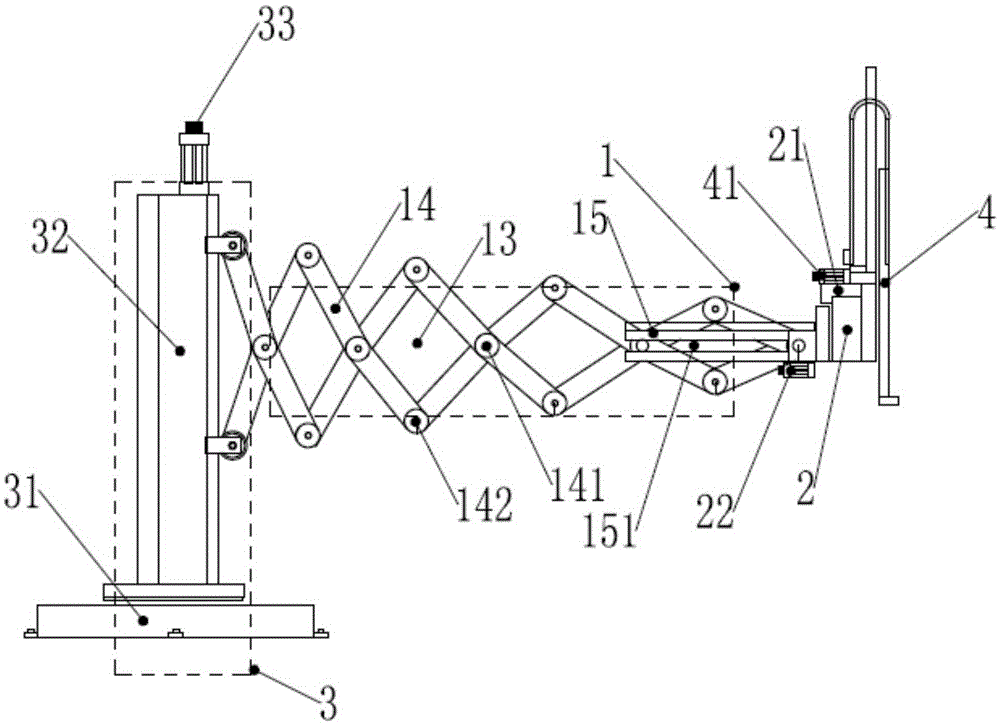

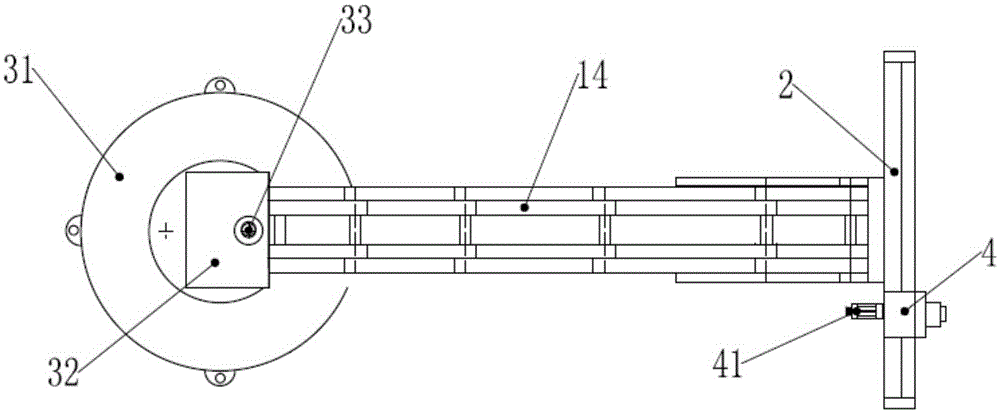

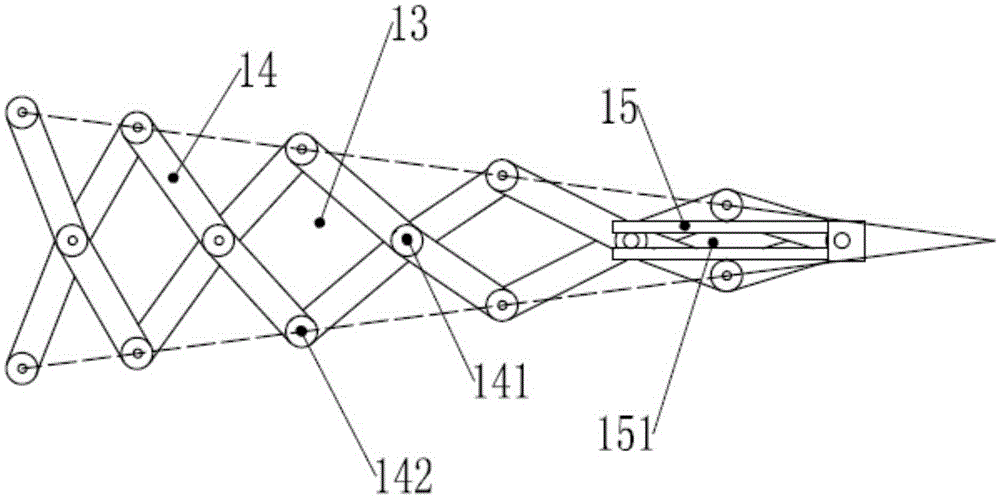

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0021] A T-shaped manipulator, comprising a tapered telescopic arm 1, a transverse guide rail assembly 2, and a fuselage 3; one end of the tapered telescopic arm 1 is mounted on the fuselage 3, and the other end is mounted with the transverse guide rail assembly 2, and the transverse guide rail assembly 2 is symmetrical about the installation end.

[0022] The T-shaped manipulator is provided with a tapered telescopic arm 1 to replace the longest guide rail in the original Cartesian coordinate system manipulator, which overcomes the problem of the non-stretchability of the existing longest guide rail, and realizes the totality of the transverse guide rail. 2 moves back and forth along the telescopic direction of the tapered telescopic arm 1 in the working space, which expands the working range of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com