Rotary machining bearing device

A technology of bearing device and rotary processing, which is applied in the direction of grinding workpiece support, etc., to achieve the effect of convenient operation, improved efficiency and precision, and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

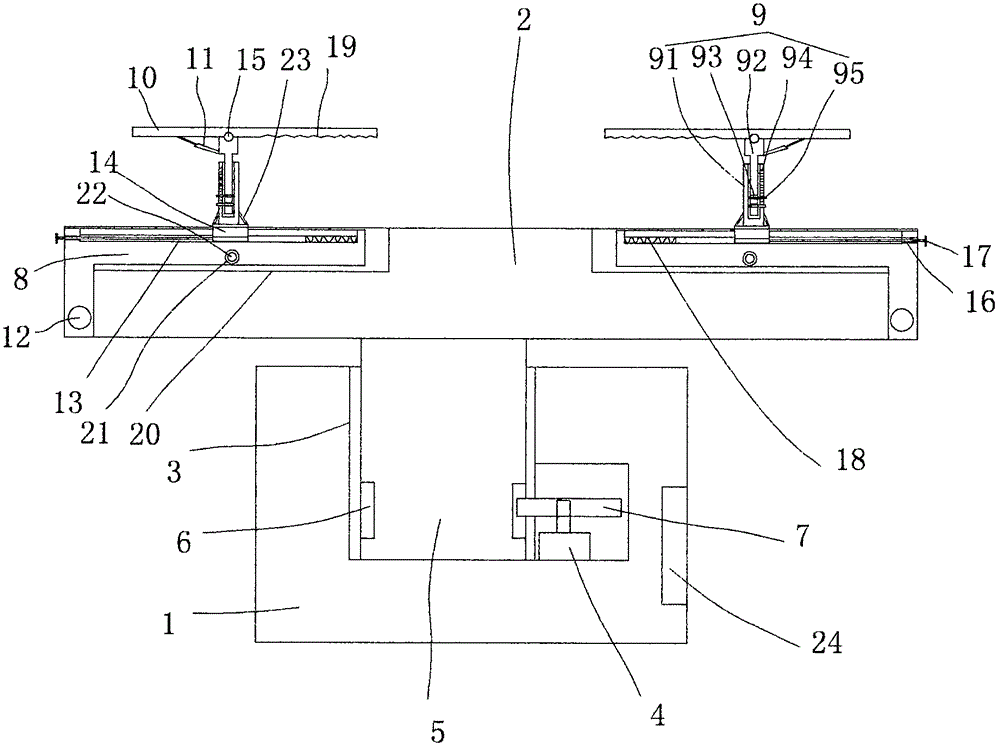

[0017] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0018] See figure 1 , a rotating processing bearing device, comprising a base 1, a bearing platform 2 arranged on the top surface of the base 1, at least two quick clamp positioning structures are uniformly arranged on the bearing platform, and a A cavity 3 with an opening on the top surface, a motor 4 is fixed in the cavity 3, a shaft 5 is fixed at the center of the bottom surface of the carrying platform 2, the shaft 5 is inserted into the cavity 3, and the shaft 5 is inserted into the cavity 3. There are tooth grooves 6 on the surface of the shaft 5, and a drive gear 7 is fixed on the main shaft of the motor 4. The drive gear 7 meshes with the tooth grooves 6 on the surface of the shaft. The quick clamp positioning structure It includes an L-shaped bottom bar 8, a telescopic pole 9, a transverse splint 10 and a clamping cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com