An automatic loading and unloading processing equipment with grinding function

A technology for automatic loading and unloading and processing equipment, which is applied in the direction of metal processing equipment, grinding/polishing equipment, grinding feed movement, etc., and can solve problems such as untreated workpiece burrs, inability to achieve workpiece clamping, and complicated equipment , to achieve the effects of high work efficiency, manpower saving and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

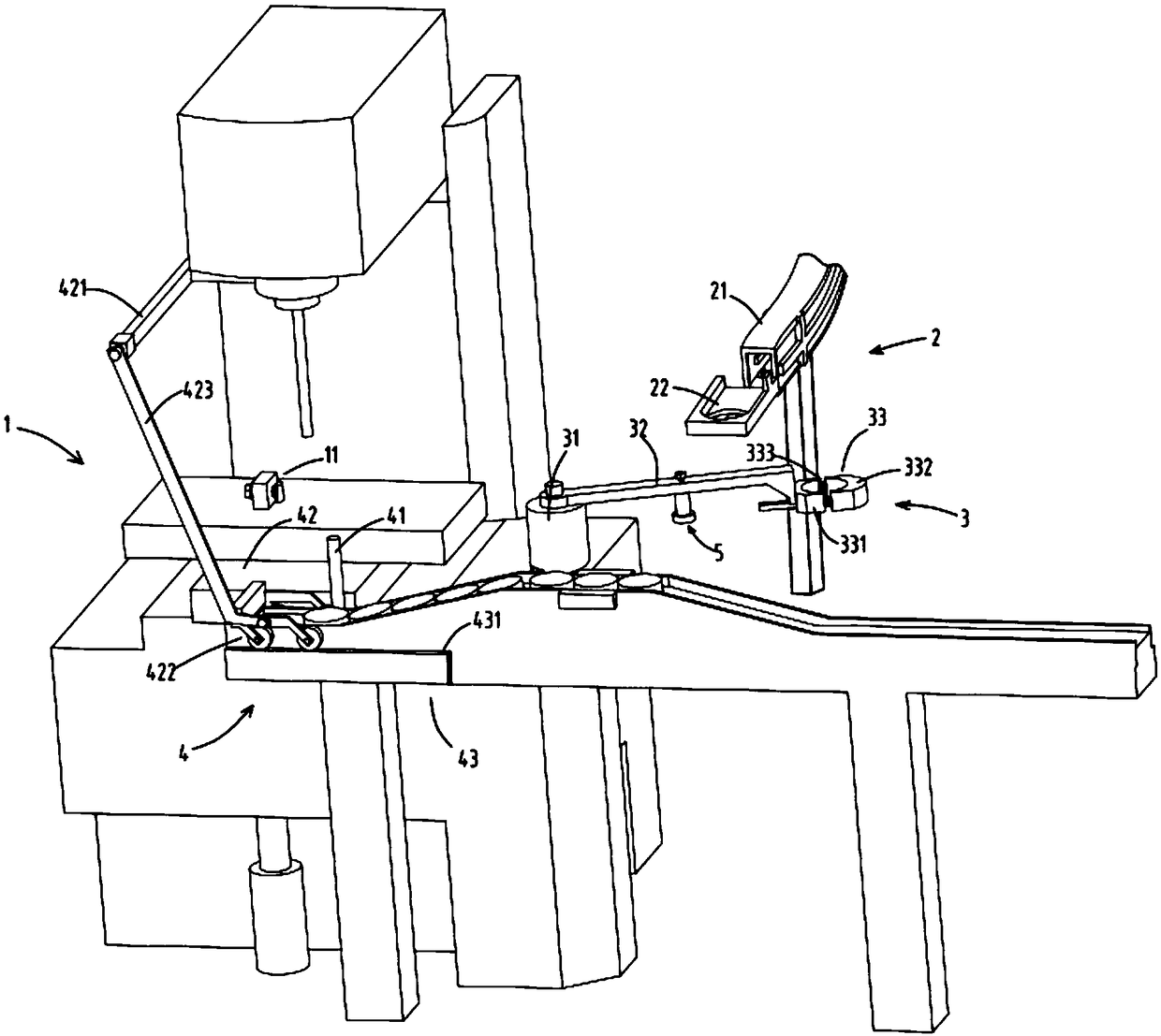

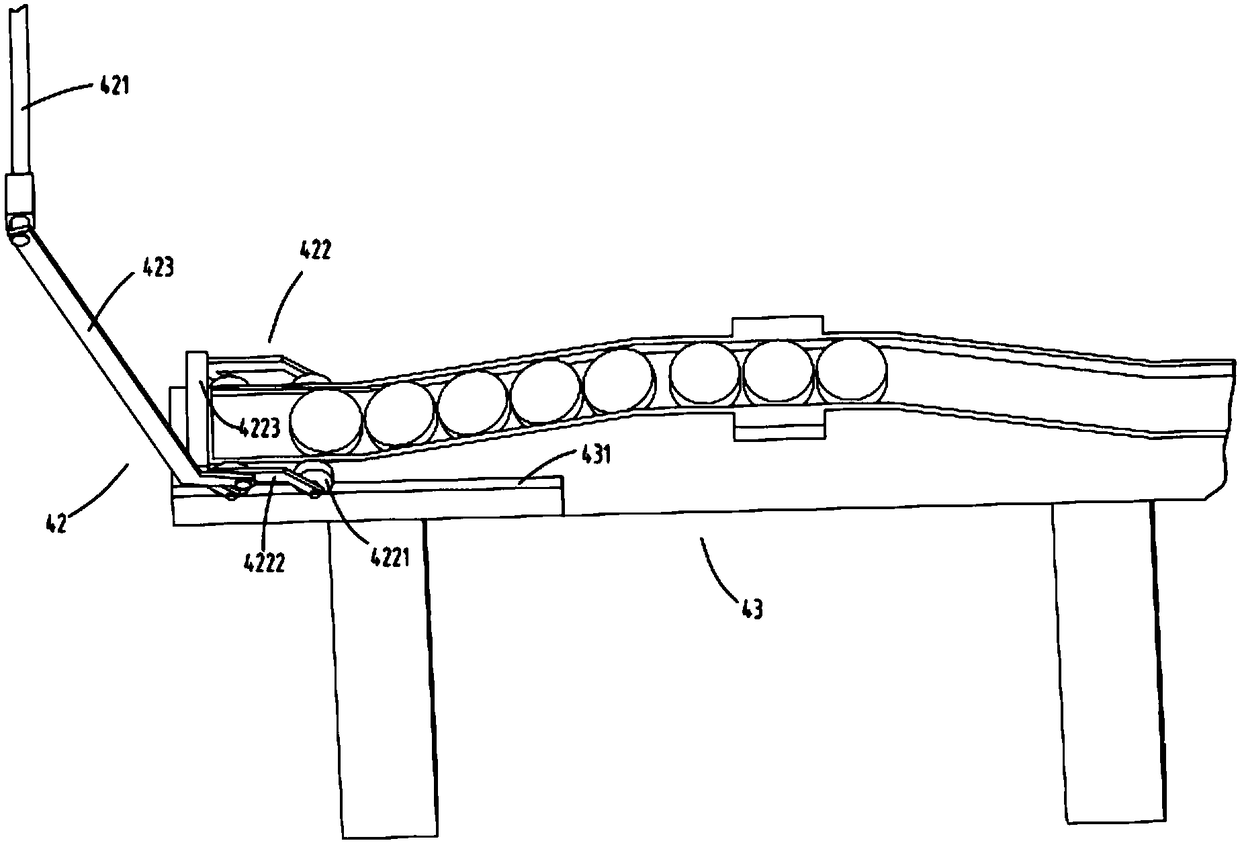

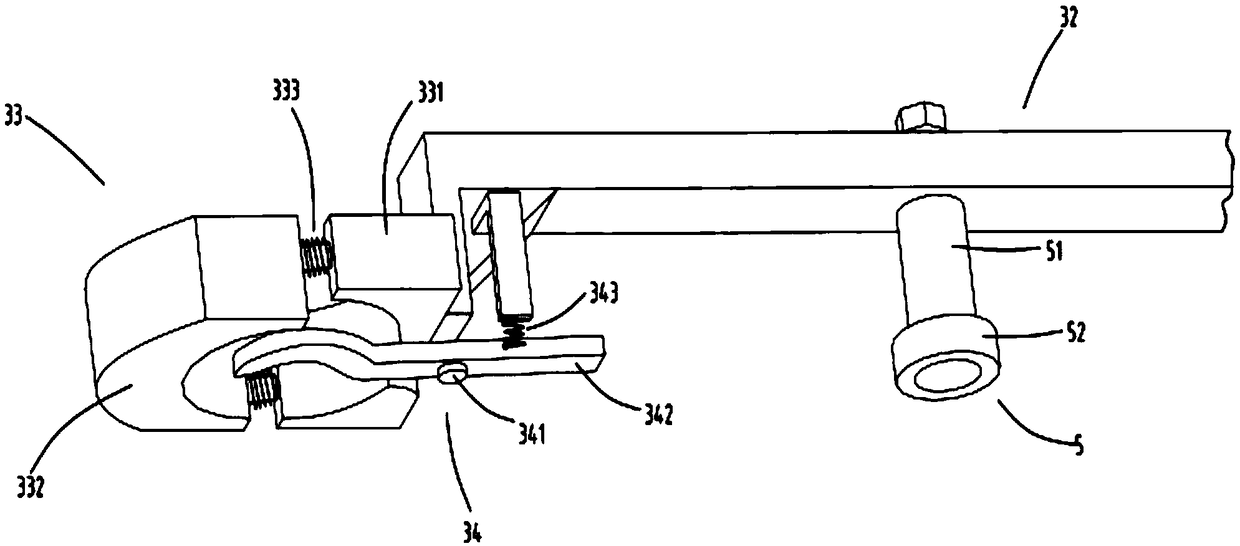

[0043] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that the pressing device 11 includes a fixed block 111, a screw 112 rotatably arranged on the fixed block 111, and a pressing block 113 fixed at the end of the screw 112; This arrangement of the device 11 makes the position of the pressing block 113 of the pressing device 11 adjustable, and the position of the pressing block 113 can be adjusted by turning the screw 112 according to the actual situation, so as to adjust the degree of tightness of the pressing block 113 against the moving clamp block 332 , can meet the clamping requirements of workpieces of different specificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com