Automatic irrational number speed ratio grinding and polishing machine

An irrational number and speed ratio technology, applied in the direction of grinding frame, grinding machine tool, grinding/polishing equipment, etc., can solve the problems of surface roughness decrease of workpiece, ripples on polished surface, repeated abrasive particle trajectory, etc., to improve the surface Effects of quality, improved stability, and low-damage machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

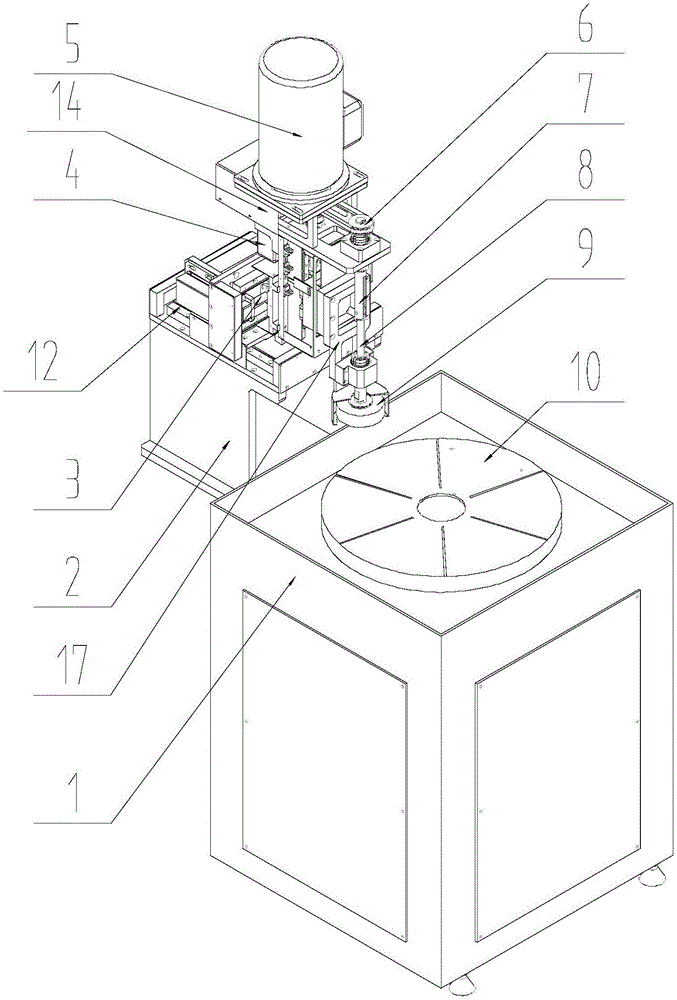

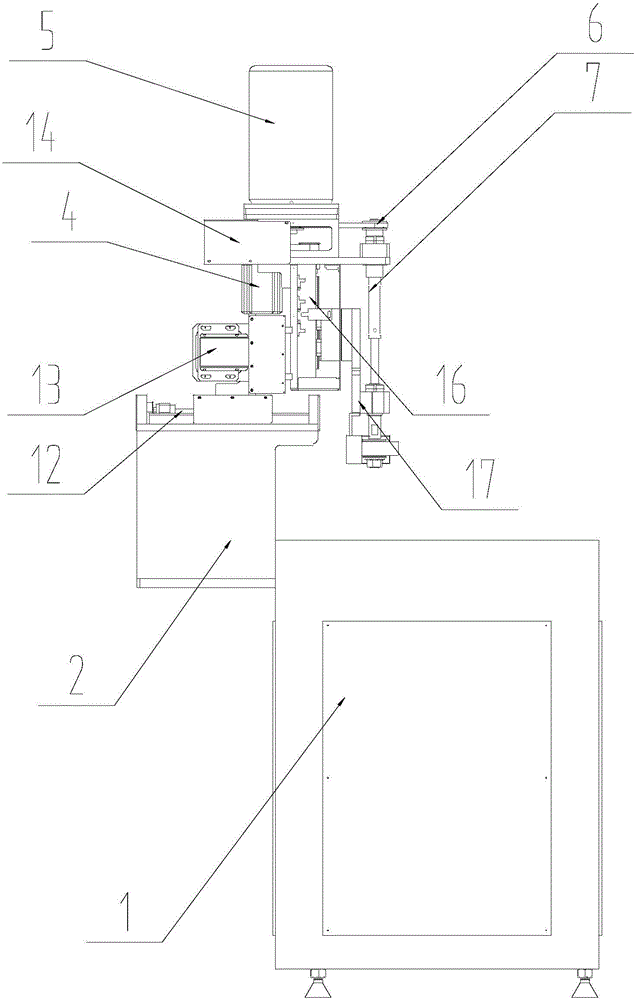

[0018] Such as Figure 1~5 As shown, an automatic irrational number speed ratio grinding and polishing machine includes a traditional grinding machine 1, a connecting seat 2, an X-axis moving slide 3, a Y-axis moving slide 12, a Z-axis moving slide 16, and an active rotating motor 5 , active synchronous pulley 6, passive synchronous pulley, motor drive shaft 7, driving shaft 8, upper grinding and polishing disc 9, lower grinding and polishing disc 10 and movable plate 17, and the connecting seat 2 is fixed on the traditional grinding and polishing disc by means of screw connection On the side wall of the machine 1, the Y-axis moving slide 12 is installed on the connecting base 2, the X-axis moving slide 3 is installed on the slider of the Y-axis moving slide 12, and the connecting base 2 is fixed on the X-axis moving slide 3 On the slider, the Z-axis moving slide 16 is ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com