Laser cutting device for small-aperture pipelines

A laser cutting and small-diameter technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that small-caliber pipe products cannot be processed, and achieve the effect of simple structure, smooth section and original shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

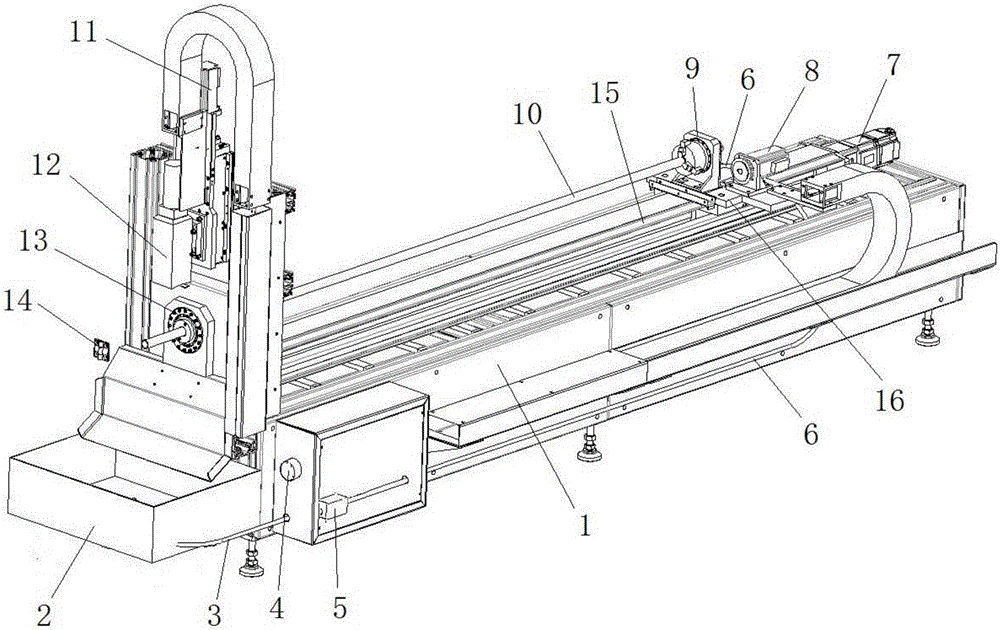

[0017] Such as figure 1 As shown, this embodiment provides a laser cutting device for small-diameter pipes, which includes a machine table; a pipe conveying mechanism is arranged above the machine for controlling the translation and rotation of the pipe; the pipe conveying mechanism A laser cutting mechanism is arranged above the left side; a receiving water tank 2 is arranged on the left side of the machine platform below the laser cutting mechanism; a water inlet pipe 3 is also arranged at the bottom of the material receiving water groove 2; the water inlet pipe 3 The other end of the water outlet is connected to the water inlet of the vacuum water pump 5 arranged on the front of the machine; the water outlet of the vacuum water pump 5 is connected to the water outlet pipe 6; the other end of the water outlet pipe 6 is connected to the right end of the pipe conveying mechanism for connecting The inner core of the right end of the pipe material 10; the position corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com