Intelligent sewing machine with independent motor feeding

A technology for independent motors and sewing machines, which is applied to program-controlled sewing machines, sewing machine components, and mechanisms for cutting threads in sewing machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

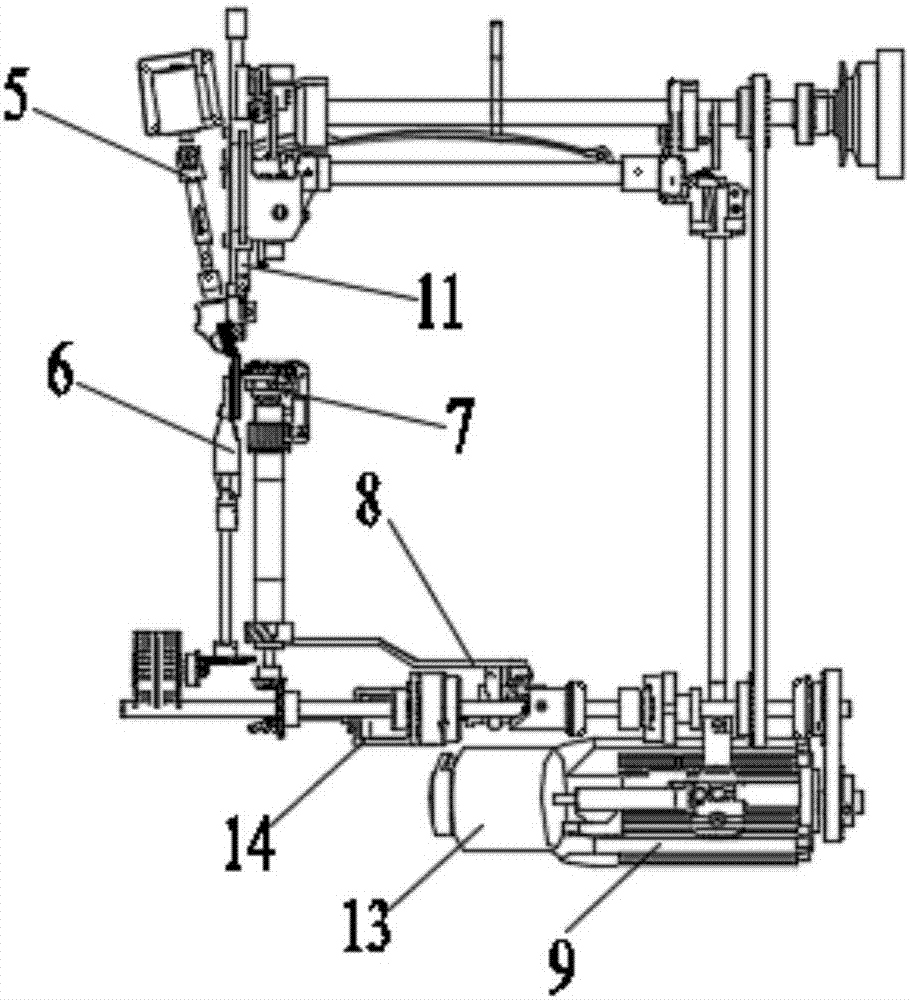

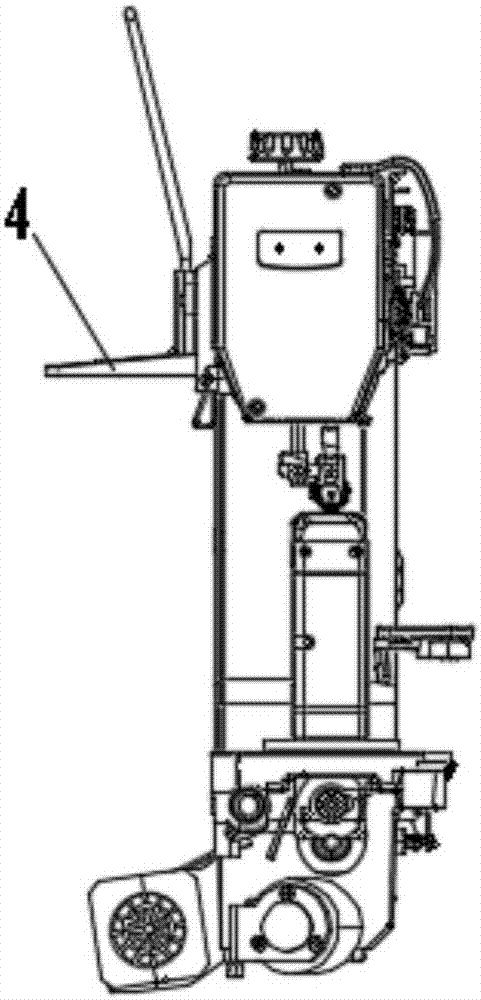

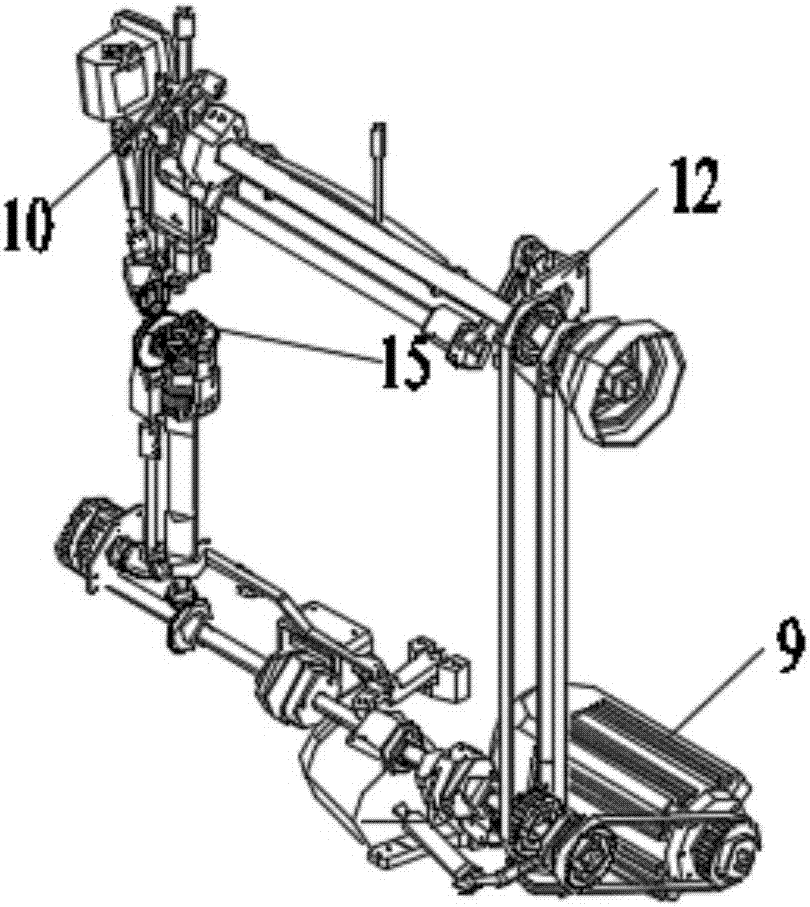

[0018] An intelligent sewing machine fed by an independent motor, comprising a thread clamping salad group 1, a casing group 2, a thread passing rod 3, a thread reel 4, an upper feeding mechanism 5, a lower feeding mechanism 6, a hook mechanism 7, a thread trimming mechanism 8, Main drive motor 9, thread take-up lever mechanism 10, needle bar mechanism 11, needle swing feeding mechanism 12, automatic presser foot lifting electromagnet 13, thread trimming electromagnet 14, thread trimming moving knife 15, thread clamping salad group 1 is set on the machine On the left side of the front side of the casing group 2, the wire reel 4 is arranged on the right side of the rear side of the casing group 2, and a wire passing rod 3 is arranged above it, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com