Molding technology for large hollow grinding ball

A molding process and hollow technology, applied in the field of metal wear-resistant materials, can solve problems such as cracks and slag holes on the surface, which are prone to cracks and slag holes on the surface, and achieve the effect of avoiding contact gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

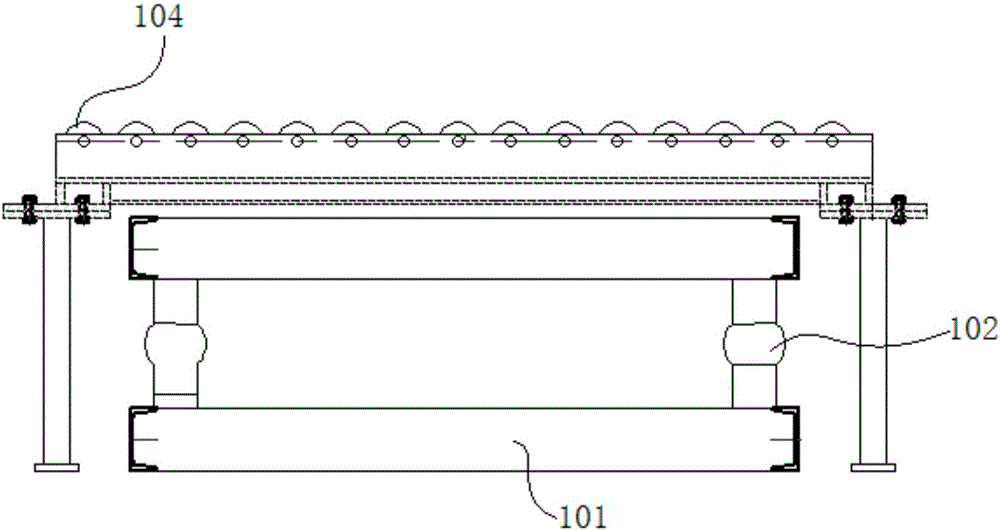

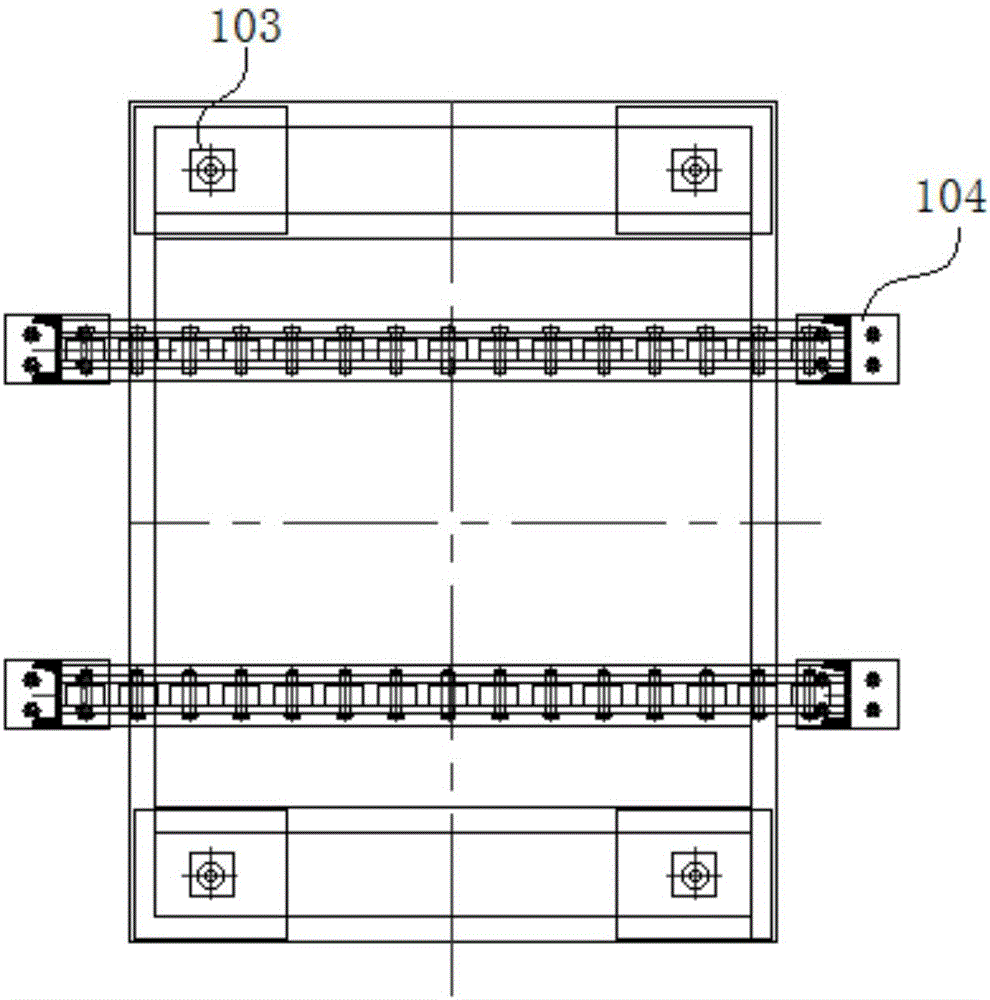

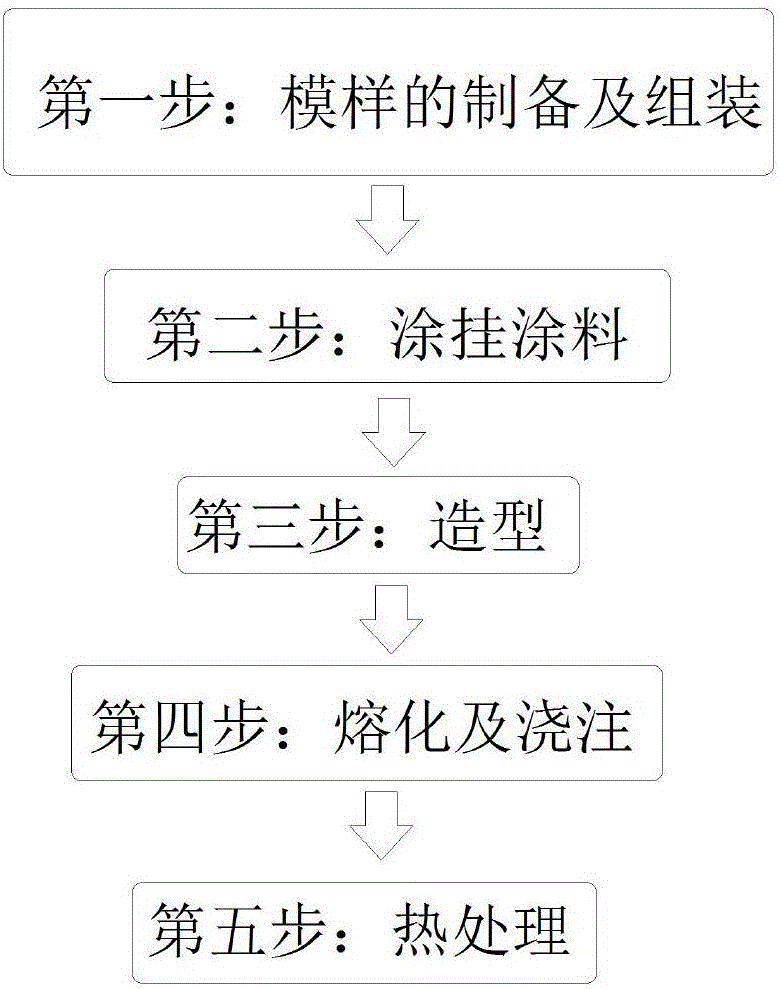

[0033] refer to Figures 1 to 3 , the manufacturing method of the large hollow grinding ball of the present embodiment includes the following steps: the first step: the preparation and assembly of the pattern; the second step: painting and hanging paint; the third step: modeling; the fourth step: melting and pouring; Five steps: heat treatment.

[0034] Among them, in the first step: use one-sixth of the hemisphere to make a foam-like foaming mold, then assemble the six-piece patterns into a hemisphere, and finally assemble the two hemispheres to form a hollow grinding ball.

[0035] In the second step: the assembled foam plastic pattern is coated with water-based zircon powder coating, and the coating thickness is 1mm;

[0036] In the third step: put the dried foam pattern into the sand box, and vibrate the sand on the vibrating unit;

[0037] The specific process of vibrating Gaza is as follows:

[0038] Stage 1: Adjust the vibration frequency, vibrate the sand box with l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com