Novel full-automatic roll forming equipment

A roll forming, fully automatic technology, applied in the field of new automatic roll forming equipment, can solve problems such as pauses, frequent braking, structural limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with embodiments, but the protection scope of the present invention is not limited to the embodiments.

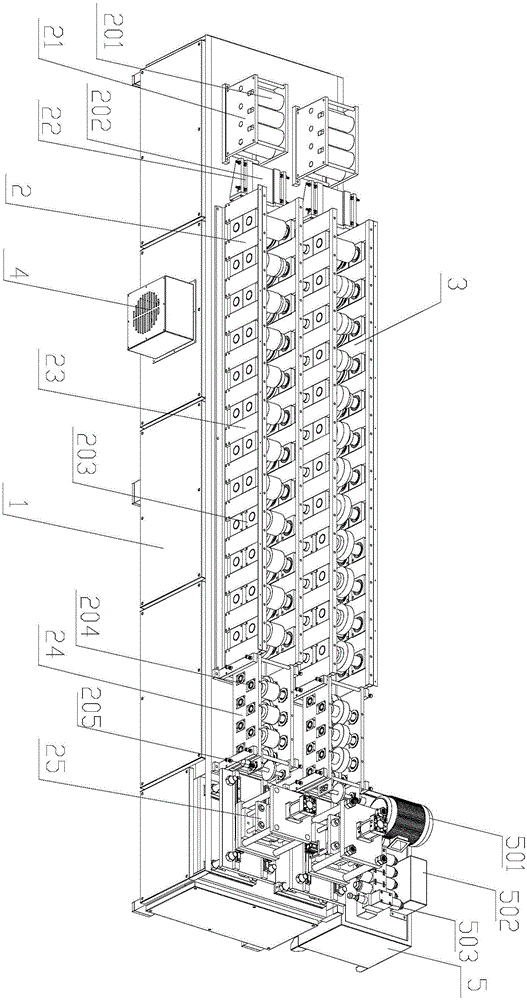

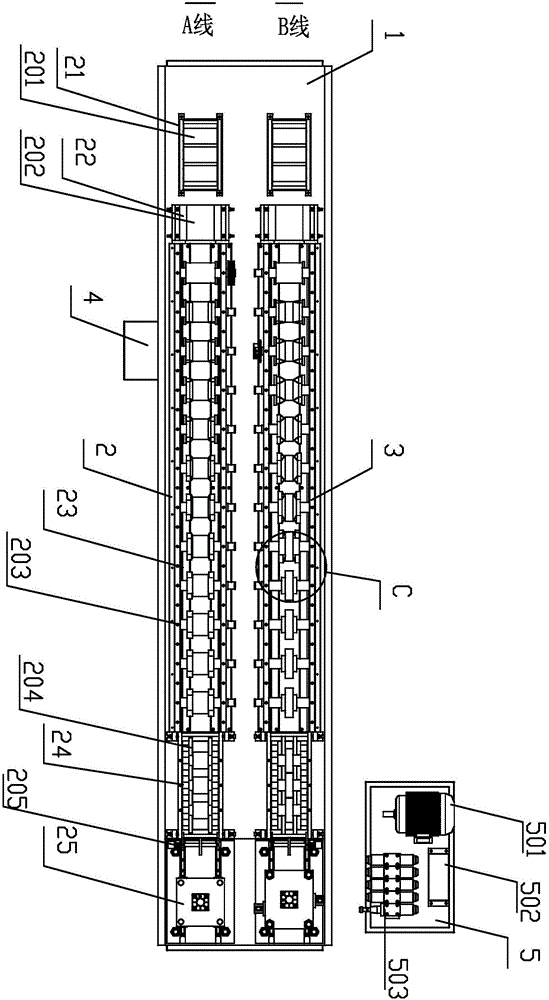

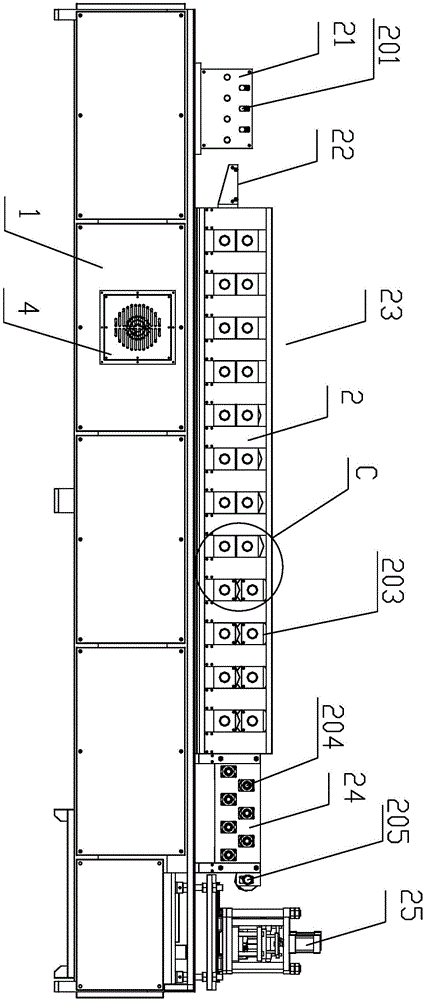

[0033] Combine Figure 1-Figure 4 As shown, a new type of fully automatic roll forming equipment has a frame 1, on which multiple roll forming production lines are arranged in parallel. In this embodiment, there are two, namely A production line 2 and B production line 3 . The structures of A production line 2 and B production line 3 can be the same or different. When the two production lines have different structures, profiles with different structures can be produced.

[0034] According to the production process, each roll forming production line includes a leveling roller set 21, a left and right correction mechanism 22, a forming roller set 23, a correction roller set 24, an encoder 205 and a cutting mechanism 25 in sequence. The leveling roller 21 is located at the foremost end of the entire produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com