Novel no-screw seam-rolling roof panel forming equipment

A technology for forming equipment and roof panels, which is applied in the field of new-type screwless seam roof panel forming equipment, and can solve problems such as structural restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

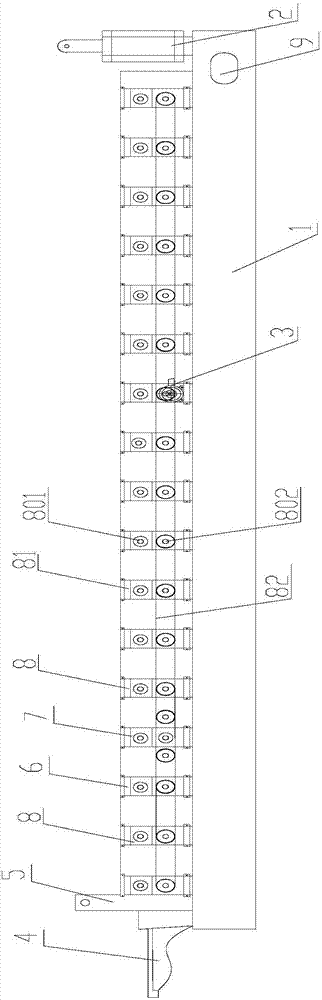

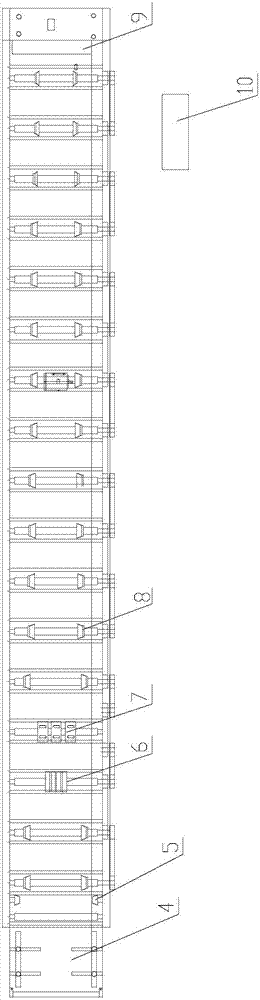

[0016] combine Figure 1-Figure 2 As shown, a new type of screwless seam roof panel forming equipment has a frame 1. It is characterized in that the forming production line arranged on the frame follows the production process: the roll forming production line includes a feeding device 4, Laminating device 5, vertical rib forming wheel 6, transverse rib forming wheel 7, forming roller group 8 and hydraulic forming shear 2, the feeding device is located at the forefront of the entire production line,

[0017] The film coating device 5 is located between the feeding device 4 and the forming roller group 8, and the forming roller group 8 is composed of 15 forming rollers 81, and each forming forming roller includes an upper roller that cooperates with each other The wheel 801 and the lower roller 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com