Piercing die for simultaneously punching five direction holes by using two different cam mechanisms, and operating method thereof

A cam mechanism, five-direction technology, applied in the direction of piercing tools, manufacturing tools, metal processing equipment, etc., can solve the problems of time-consuming and laborious, the accuracy cannot meet the requirements, and the accuracy requirements of the processed holes cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

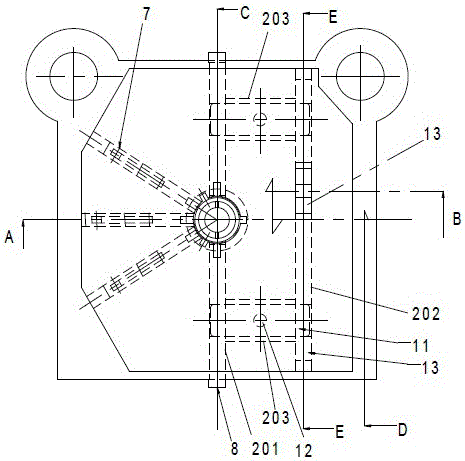

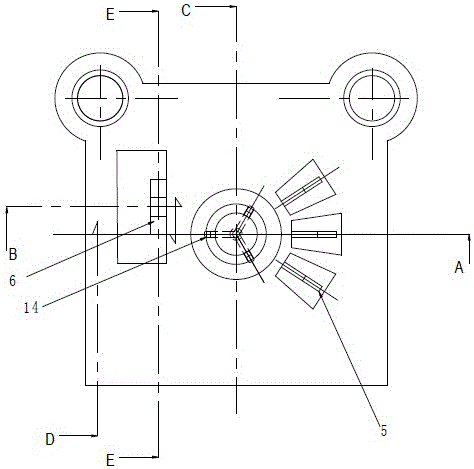

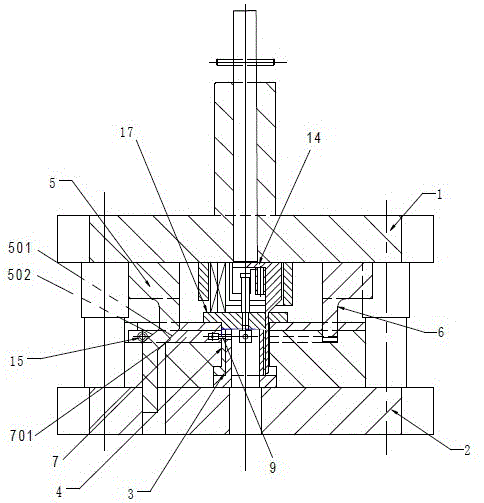

[0025] In order to make the advantages, objectives, and technical solutions of the present invention more clear, the present invention will be further explained below in conjunction with the accompanying drawings.

[0026] The punching die of the present invention uses two different cam mechanisms to simultaneously punch five-direction holes, including upper and lower dies 1, 2 and a punching lower die sleeve 3 arranged above the middle part of the lower die, and the cover-shaped thin shell to be punched The workpiece 4 is covered on the upper part of the punching lower die sleeve 3. The lower part of the upper die 1 is provided with a moving cam punch 5 and a single-action double-sided cam punch 6. The lower die is provided with three groups of moving cams. Three radial punch slides 7 driven by the punch rod 5 and a pair of opposing punch slides 8 driven by the single-action double-sided cam punch 6, the inside of each radial punch slide 7 A radial hole punch 9 is provided at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com