Ceramic production spray cleaning device

A technology for cleaning devices and ceramics, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems that do not meet the actual needs of ceramic production, cannot guarantee the surface wetness of objects, and high cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

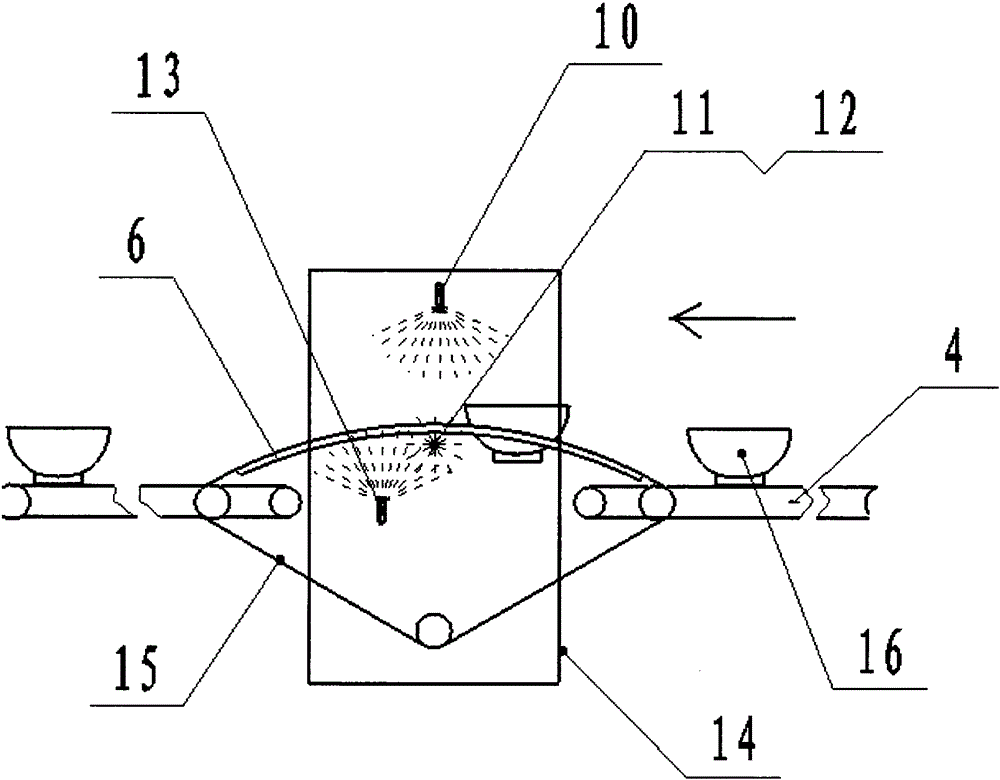

[0019] Such as figure 1 As shown, the automatic water mist wetting machine is installed on the production line according to the sequence of the production process and the blank conveyor belt is used as the reference. The automatic water mist wetting machine is equipped with a transmission belt transition bridge that lifts the blank body overhead, and the two ends of the transmission belt transition bridge are connected. Blank conveyer belt 4, the bracket 6 of drive belt transition bridge supports transition bridge conveyer belt 15, and transition bridge conveyer belt is driven by roller and the uniform speed of blank conveyer belt.

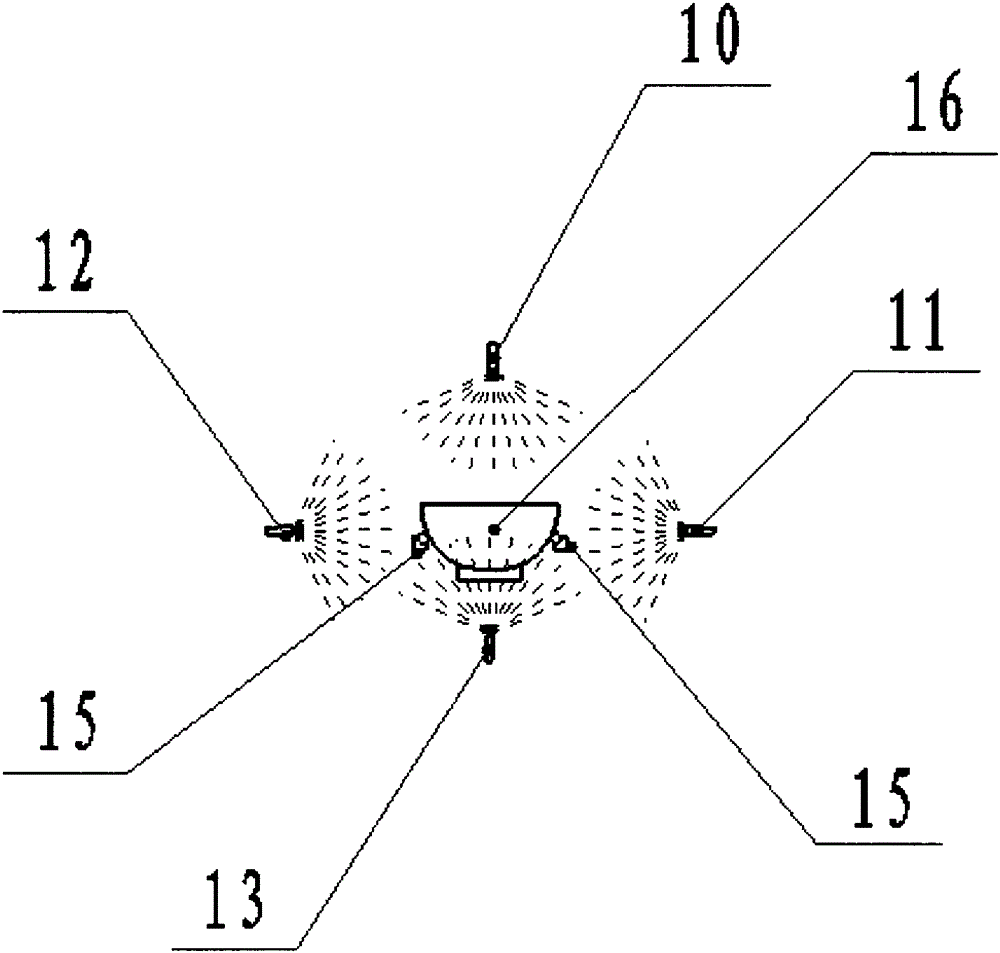

[0020] The automatic water mist wetting machine includes an upper atomization nozzle 10, a middle atomization nozzle and a lower atomization nozzle 13, and an atomization chamber 14. The blank conveyor belt 4 passes through the atomization chamber laterally through the opening of the atomization chamber, and the upper atomization nozzle , the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com