Bubble charging electrode electrostatic spraying nozzle

A charging electrode and nozzle technology, which is applied to electrostatic spray devices, spray devices, spray discharge devices, etc., can solve the problems of low utilization rate of pesticides and environmental pollution, and achieve the effects of increasing adhesion, improving utilization rate, and increasing charging time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and example the present invention will be further described

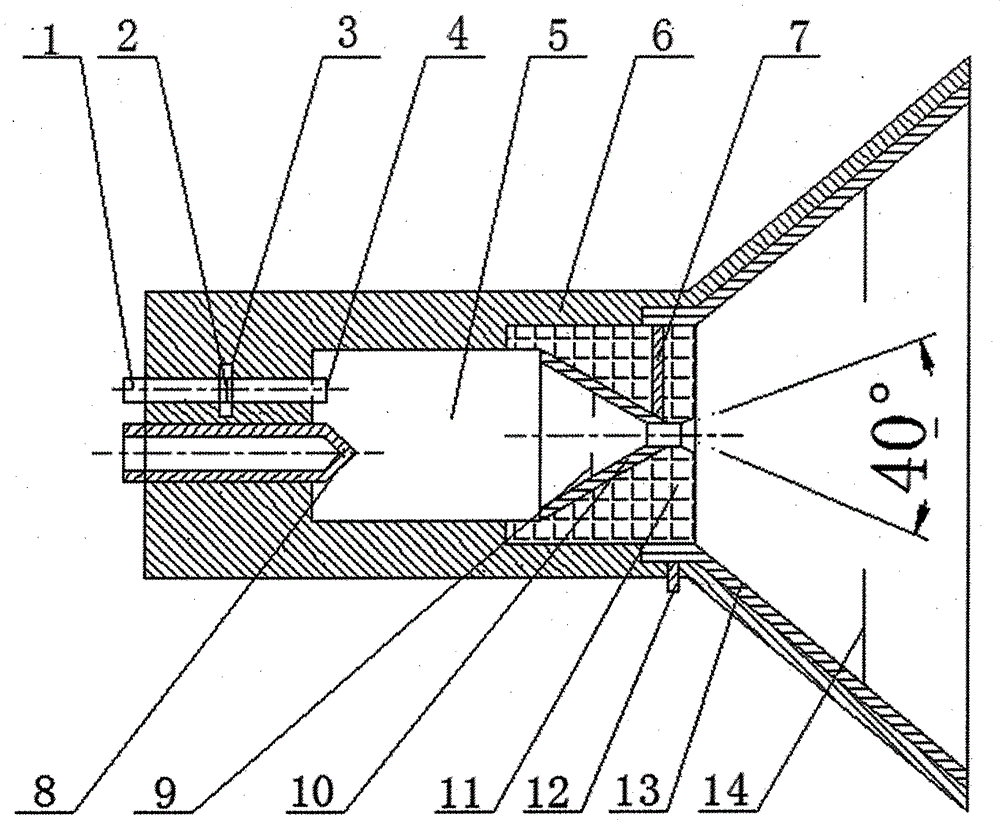

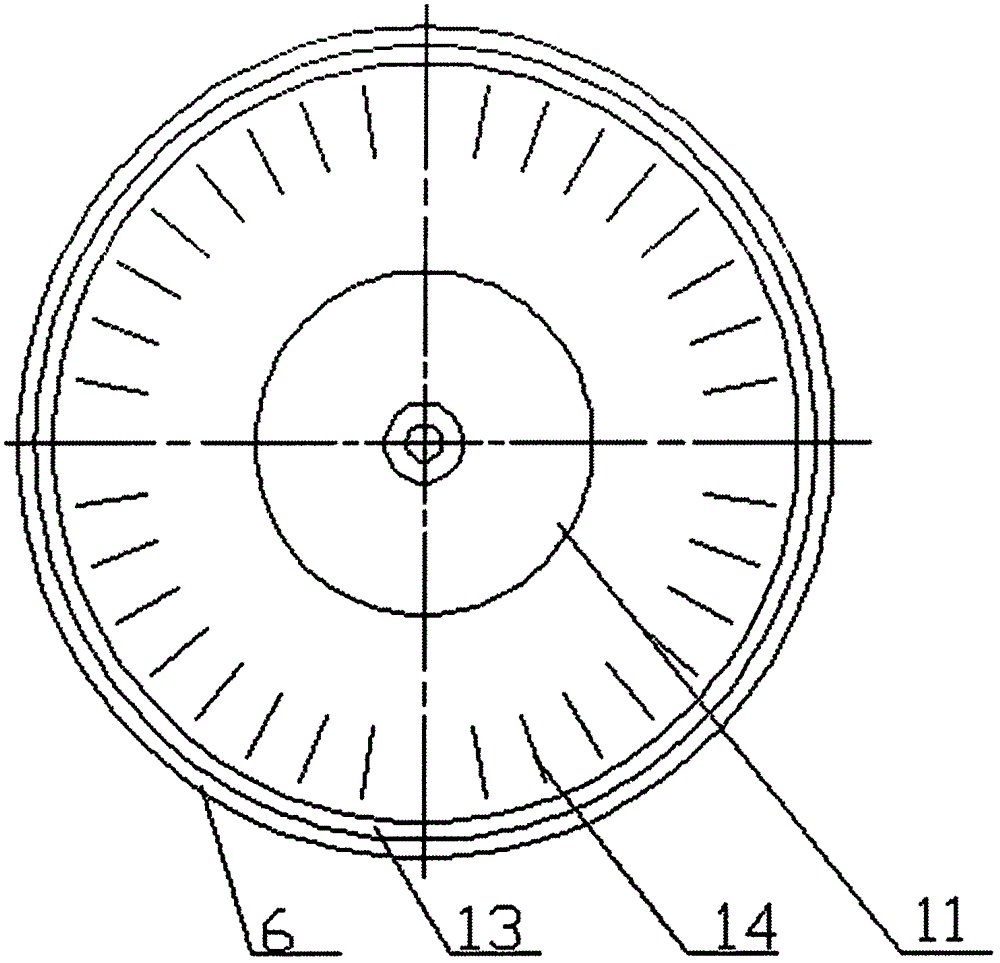

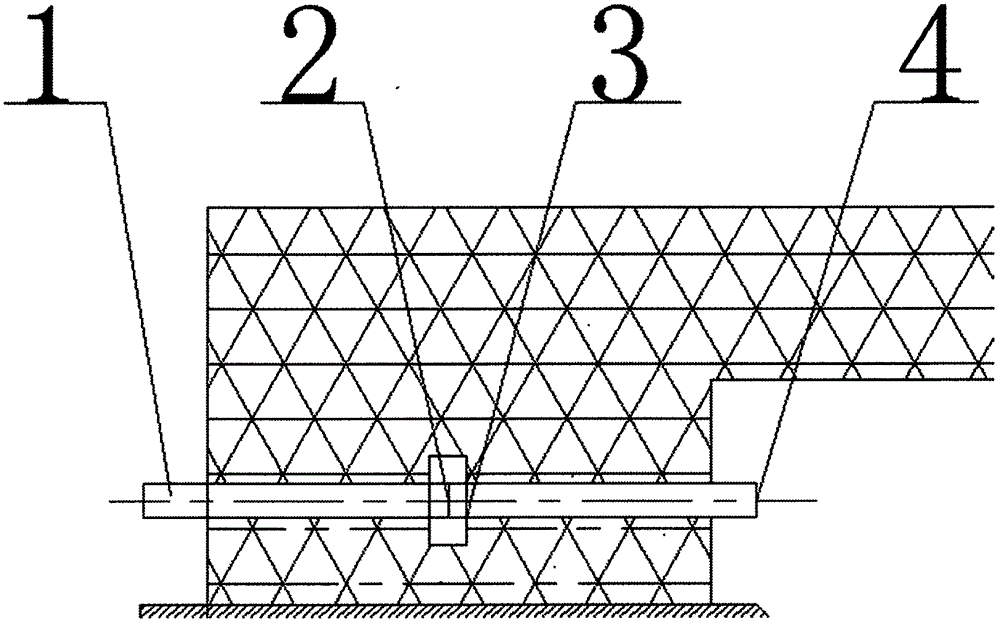

[0016] The present invention is used in conjunction with an electrostatic sprayer, such as figure 1 As shown, the present invention includes No. 1 liquid inlet pipe (1), filter screen (2), connector (3), No. 2 liquid inlet pipe (4), mixing chamber (5), insulating sleeve (6), conductive copper column (7), bubble generator (8), nozzle (11), inner tapered tubular charging electrode (10) nested in the inner cavity of nozzle (11), inner needle-shaped charging electrode (9), micro socket (12 ), an outer tapered tubular charging electrode (13), and an outer needle-shaped charging electrode (14). The shower head (11) is made of insulator material. The No. 1 cylindrical liquid inlet pipe (1) and the No. 2 cylindrical liquid inlet pipe (4) are connected through the joint (3), and the filter screen (2) is fixed inside the joint (3); the No. 2 liquid inlet pipe (4) The cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com