Two-stage crushing device for graphite for manufacturing negative electrode materials for lithium ion batteries

A technology for lithium ion batteries and negative electrode materials, which is applied in the fields of removing smoke and dust, cleaning methods and utensils, and grain processing, etc., can solve problems to be improved, and achieve the effects of uniform size, improved crushing speed, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

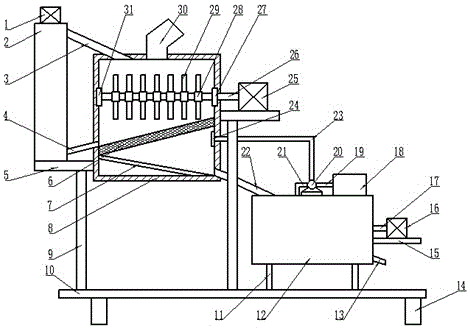

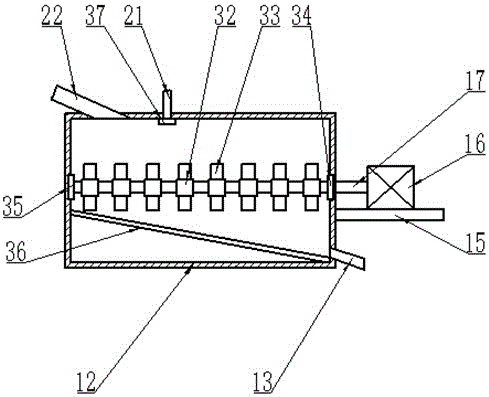

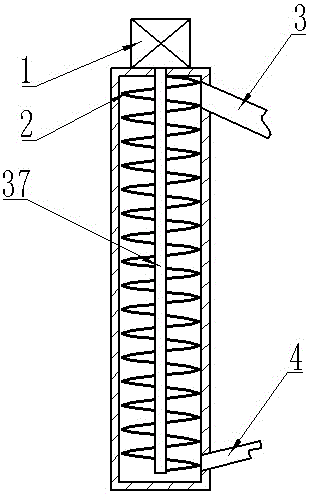

[0018] see Figure 1-3, a lithium-ion battery negative electrode material secondary crushing device, including a first-stage crushing device, a second-stage crushing device and a dust removal device; the first-stage crushing device includes a first motor 1, an upper barrel 2, a second guide Material box 3, first material guide box 4, carrier plate 5, screen plate 6, first material guide plate 7, first stage crushing box 8, support column 9, base 10, support base 14, third material guide Case 22, the third motor 25, the first rotating shaft 26, the first bearing 27, the first crushing blade fixed sleeve 28, the first crushing blade 29, the charging box 30, the second bearing 31 and the screw rod 38; the supporting base 14 Welded on the lower end surface of the base 10, it has the function of supporting the whole device; the base 10 is welded on fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com