Ceramic carrier catalyst adsorption apparatus

A catalyst device and ceramic carrier technology, which is applied in the direction of liquid injection device, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problems of uneven distribution and poor consistency of slurry, achieve automatic adsorption and meet product quality The need for consistency, the effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

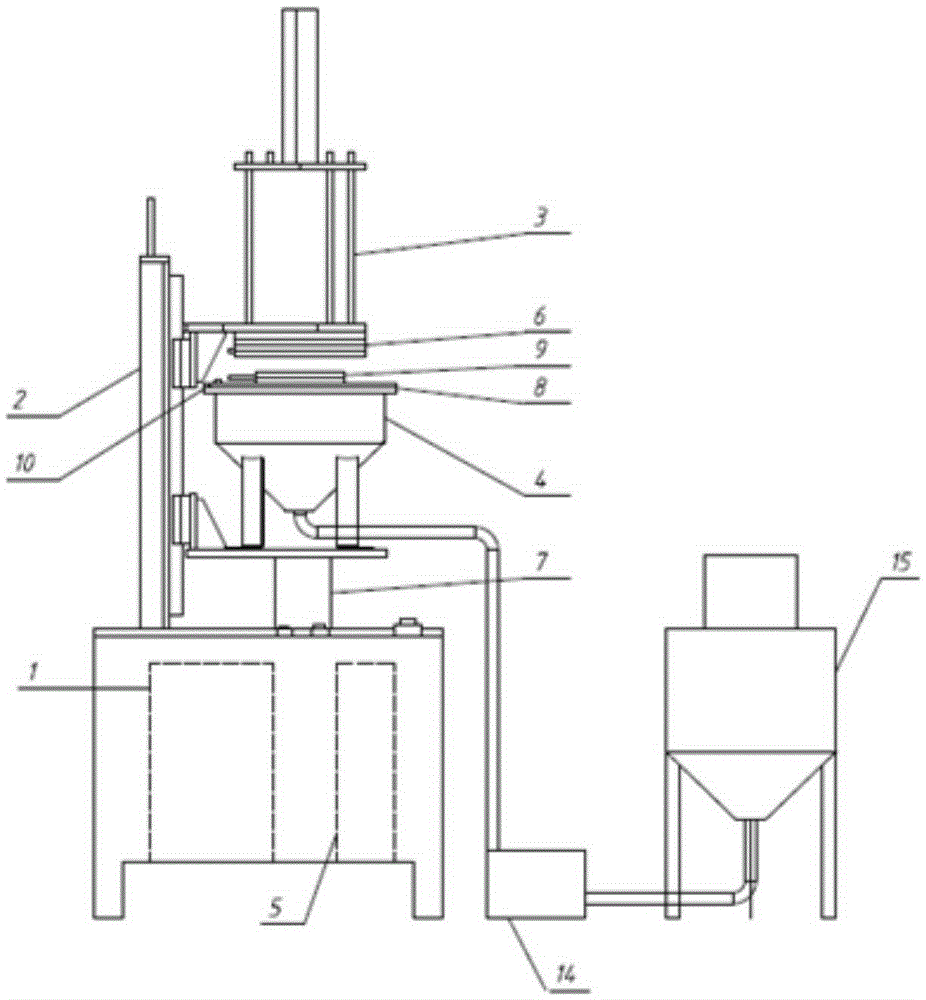

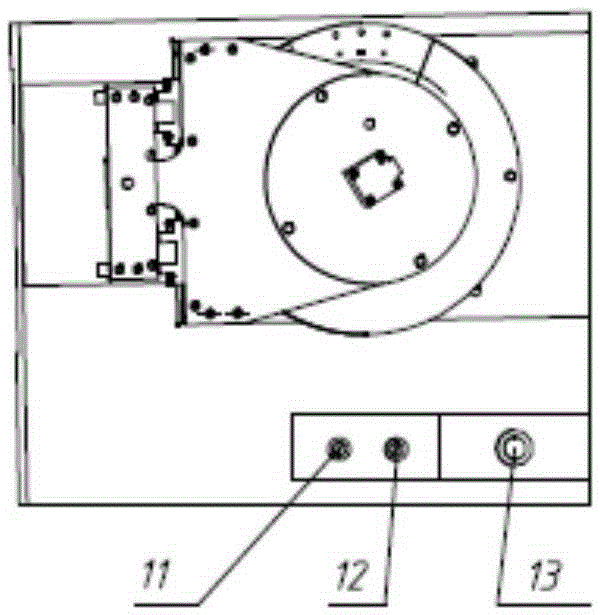

[0018] During specific implementation, combined with Figure 1-2 , a ceramic carrier adsorption catalyst device, including a console 1, a bracket rail 2, a vacuum pump 3, a slurry pot 4, a control unit 5, a telescopic air pump 7, a control pump 14 and a mixing bucket 15. The support guide rail 2 is installed on the console 1, the vacuum pump 3 is fixed on the support guide rail 2, the slurry pot 4 is connected with the telescopic air pump 7 and slides on the support guide rail 2 driven by the telescopic air pump 7. A bolt fixing plate 8 is installed on the slurry pot 4, and a liquid level controller 10 is installed on the bolt fixing disk 8, and the liquid level controller 10 is connected to the control unit 5 through a circuit. The control uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com