Fire coal desulfuration preparation equipment for haze prevention

A technology for burning coal and smog, applied in mixer accessories, dissolving, mixer and other directions, can solve the problems of incomplete preparation, slow preparation, uneven preparation, etc., and achieve the effect of complete preparation, fast preparation and prolong life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

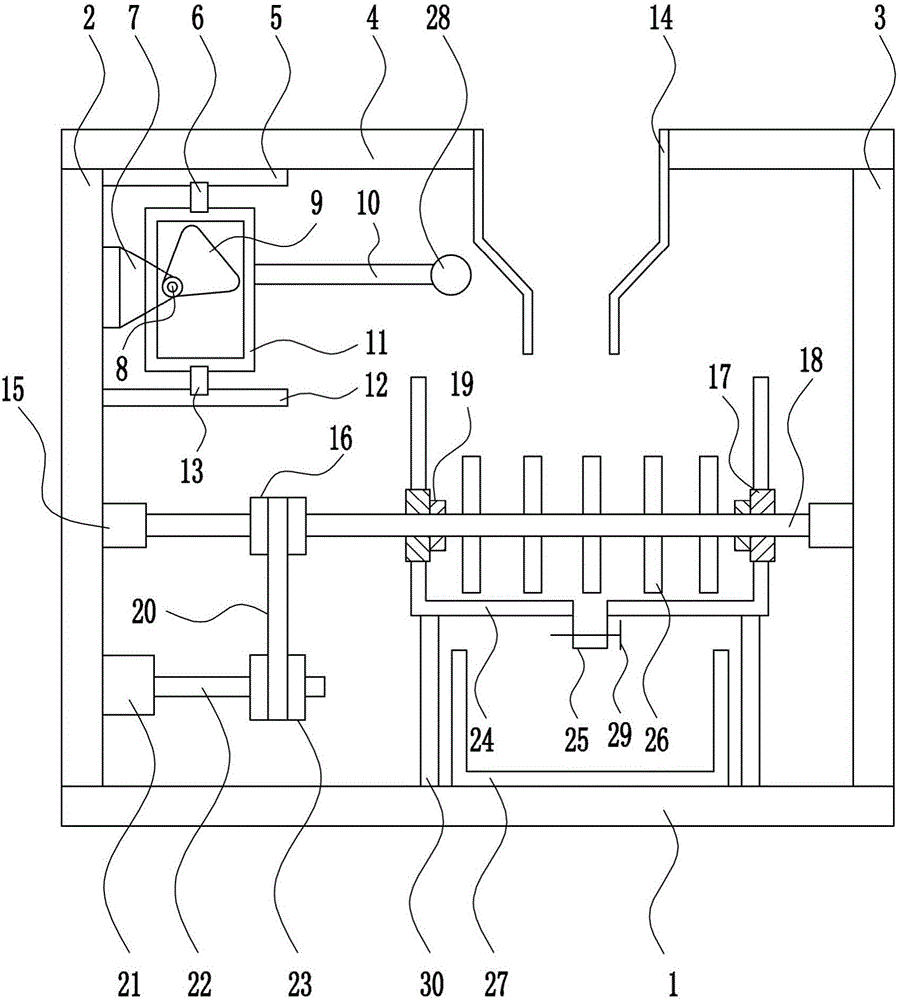

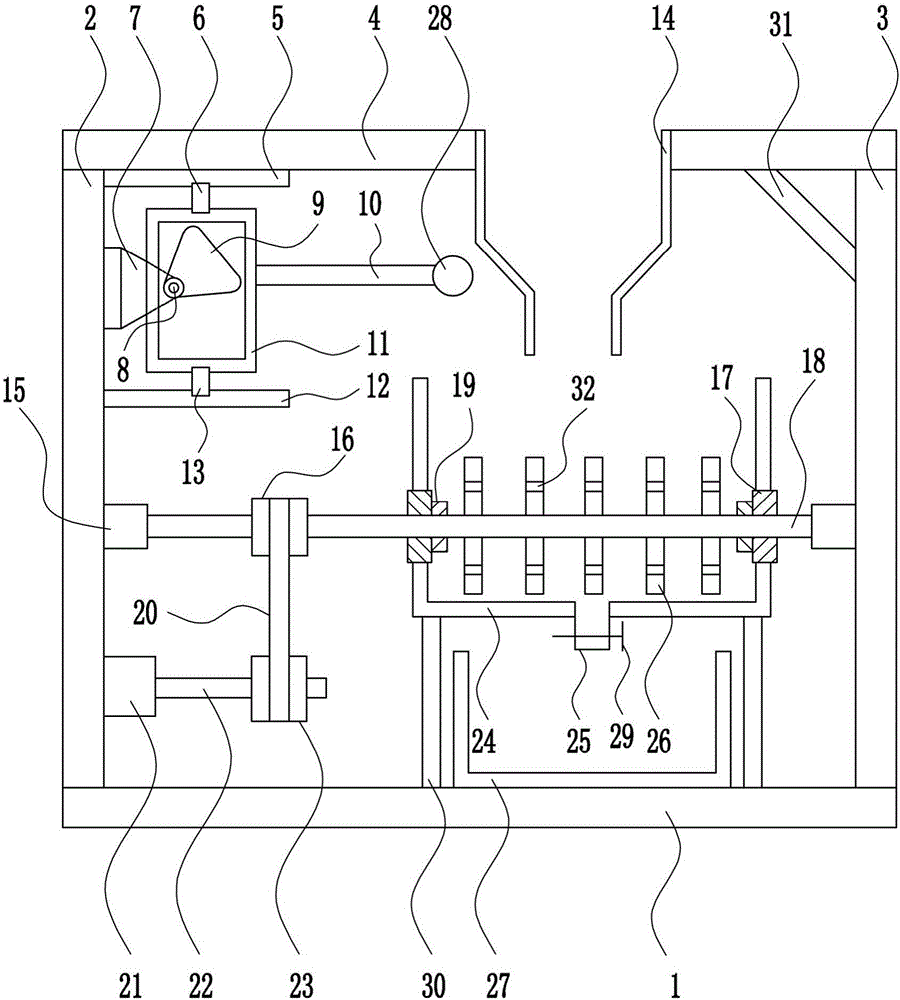

[0028] A coal-fired desulfurization preparation equipment for smog prevention, such as Figure 1-3 As shown, it includes bottom plate 1, left frame 2, right frame 3, top plate 4, first slide rail 5, first slider 6, mounting seat 7, first motor 8, disc cam 9, connecting rod 10, moving Frame 11, second slide rail 12, second slider 13, feed hopper 14, first bearing seat 15, small pulley 16, second bearing seat 17, first rotating shaft 18, seal ring 19, flat belt 20, the first Second motor 21, second rotating shaft 22, large pulley 23, mixing frame 24, discharge pipe 25, stirring blade 26, collecting frame 27, rubber hammer 28, electric control valve 29 and pole 30, the left end of the bottom plate 1 is welded with a left frame 2. The upper part of the right side of the left frame 2 is connected with the installation seat 7 by means of bolt connection, and the first motor 8 is fixedly connected to the installation seat 7 by means of bolt connection, and the output shaft on the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com