Venturi tube bundle type dust and mist eliminator

A Venturi tube and tube-bundle technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve problems such as low removal efficiency, gypsum rain in chimneys, and unavoidable carrying a large amount of fine dust and gypsum droplets. Achieve the effect of avoiding secondary entrainment and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the drawings:

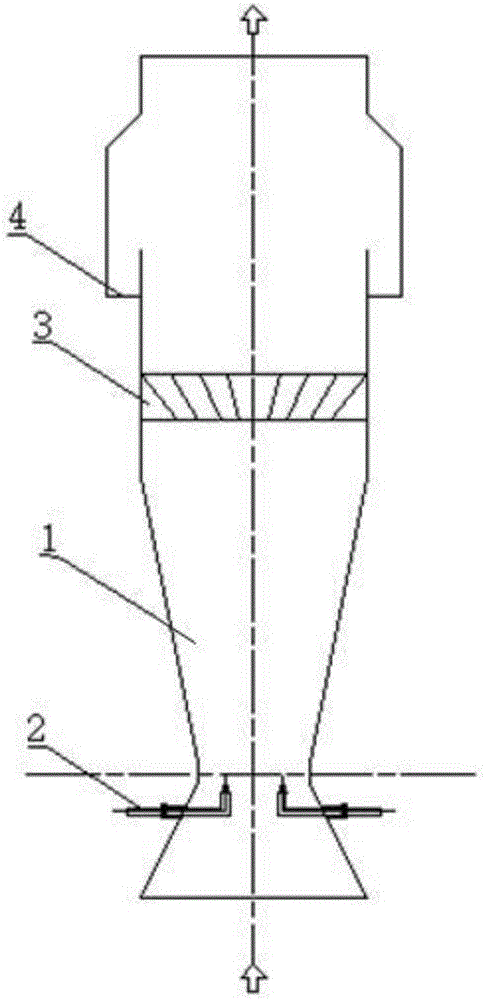

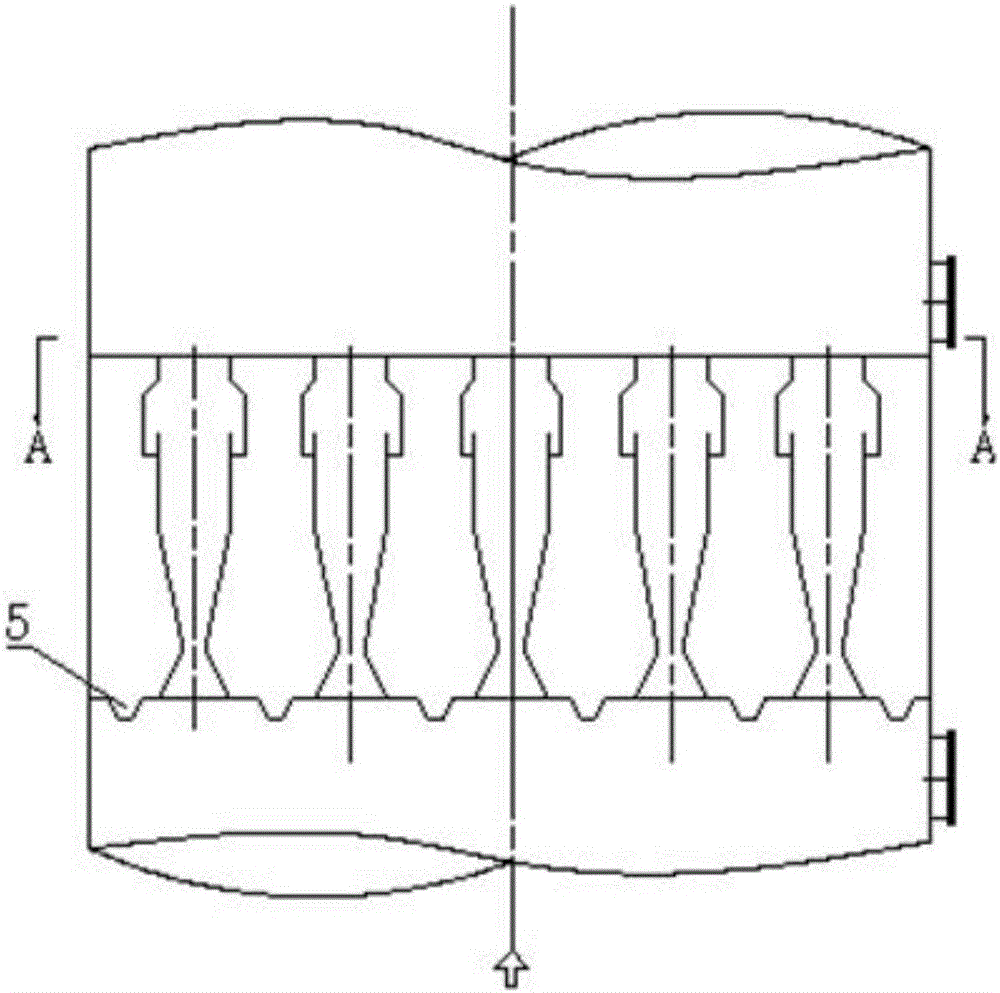

[0021] Combine Figure 1 to Figure 3 As shown, the Venturi tube bundle type dust and mist eliminator disclosed in this embodiment includes a Venturi tube 1, a single-fluid spray gun 2, a centrifugal device 3, an enlarged chamber 4 and a drain plate 5;

[0022] The bottom end of the venturi tube 1 is installed on the round hole of the drainage plate 5. There are several single-fluid spray guns 2 on the outer wall of the bottom. The sprayed water droplets are transformed into smaller droplets through the Venturi effect, which greatly improves the water droplets. The chance of collision with dust is more conducive to the merger and growth of fine dust.

[0023] A centrifugal device 3 is arranged on the upper inner wall of the venturi tube 1, and the combined and grown dust-containing liquid droplets are separated from the flue gas by the centrifugal action of the centrifugal device 3.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com