Stainless steel high-pressure filter

A high-pressure filter, stainless steel technology, applied in the direction of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., to achieve the effect of convenient use, high filtration effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

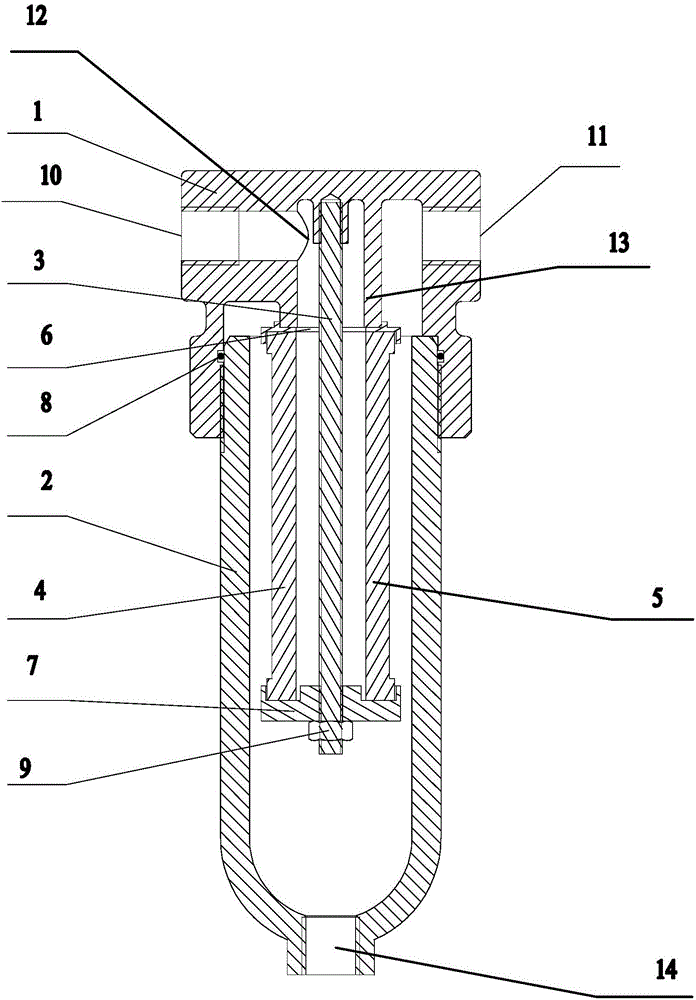

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, a stainless steel high-pressure filter includes an upper casing 1, a lower casing 2, a screw rod 3, a first filter element 4, a second filter element 5, an upper end cover 6 and a lower end cover 7; the upper end of the lower casing 2 An external thread is provided, and the lower end of the upper case 1 is provided with an internal thread matched with the lower case 2, and the upper case 1 and the lower case 2 are connected by the external thread and the internal thread, and the upper case 1 and the lower case A sealing ring 8 is provided between the shells 2, a first air vent 10 and a second air vent 11 are respectively provided on both sides of the end of the upper shell 1, and a partition is provided between the first air vent 10 and the second air vent 11. 13. The partition 13 separates the first air vent 10 and the second air ven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com