Compound anti-haze mask

An anti-fog, composite technology, applied in protective clothing, clothing, clothing, etc., to achieve good anti-fog, good effect, high space purification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of a composite anti-fog and haze mask, the specific steps are as follows:

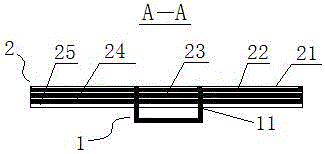

[0033] 1) The inner layer of plant fiber non-woven fabric 25, graphene foam layer 24, nano-silver coated net 23, nano-titanium dioxide coated net 22 and PP non-woven fabric layer 21 are stacked in sequence to form the mask body 2;

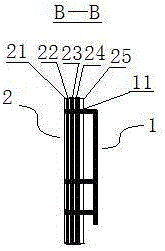

[0034] 2) A fixed blind hole is provided on the inner side of the above-mentioned mask body 2, and the fixed blind hole runs through the inner plant fiber non-woven fabric 25, the graphene foam layer 24, the nano-silver coating net 23 and the nano-titanium dioxide coating net 22 in sequence, and the The legs 11 of the support frame 1 are inserted into the fixed blind holes to form a mask assembly;

[0035] 3) Put rubber raw materials into the hot-pressing mold, place the mask assembly in the hot-pressing mold, heat the hot-pressing mold, the heating temperature of the hot-pressing mold is 80-150°C, and the holding time is 15-60 minutes. Make rub...

Embodiment 1

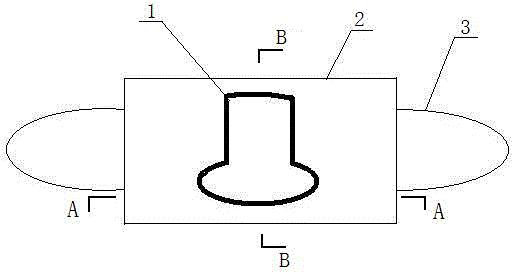

[0038] Embodiment 1: as Figure 1 to Figure 3 Shown, structure of the present invention is included in the inner surface of mouth mask successively from inside to outside and is inner plant fiber non-woven fabric 25, graphene foam layer 24, nano-silver coating net 23, nano-titanium dioxide coating net 22, outer layer The PP non-woven fabric layer 21 and the support frame 1 are composed.

[0039] The support frame 1 is a protruding "convex" type device and is provided with a foot 11 on one side (such as Figure 4 shown), the device passes the inner layer of plant fiber non-woven fabric 25, graphene foam layer 24, nano-silver coated net 23, nano-titanium dioxide coated net 22 and outer PP non-woven fabric layer 21 through the support frame 1 The legs 11 are multi-layer components, the heating temperature of the hot-pressing mold on the hot-press machine is 100° C., the temperature is kept for 40 minutes, and then naturally cooled and hot-pressed to fix the composition. The com...

Embodiment 2

[0045]Embodiment 2: The heating temperature of the hot-press mold on the hot-press machine of the present invention is 110° C., and the temperature is kept for 30 minutes.

[0046] In the production of the graphene foam layer 24, the hot-pressed preform with a thickness of 1.1mm was sintered in a vacuum furnace at 300°C for 50 minutes, and the graphene foam layer prepared by the chemical vapor deposition (CVD) method was controlled to have a thickness of 1.1mm.

[0047] The thickness of the nano-silver coated mesh 23 is 1.0 mm.

[0048] The nano-titanium dioxide coated mesh 22 has a thickness of 0.4mm.

[0049] The thickness of the PP non-woven fabric layer 21 is 0.7 mm.

[0050] Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com