Novel shred feeding machine

A wire feeding machine, a new type of technology, applied in the application, tobacco, cigarette manufacturing and other directions, can solve the problems of large error in the amount of tobacco used, accurate statistics, and difficulty in counting and distinguishing the amount of use in cigarette workshops, and achieve the effect of preventing material jamming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

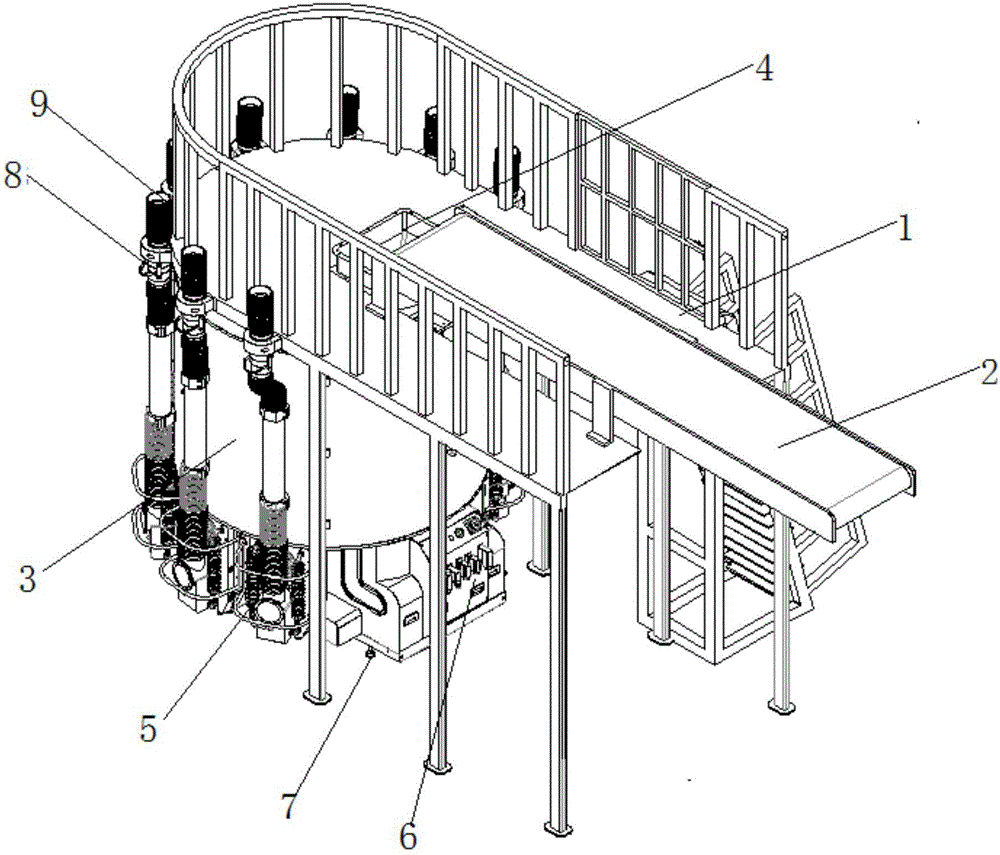

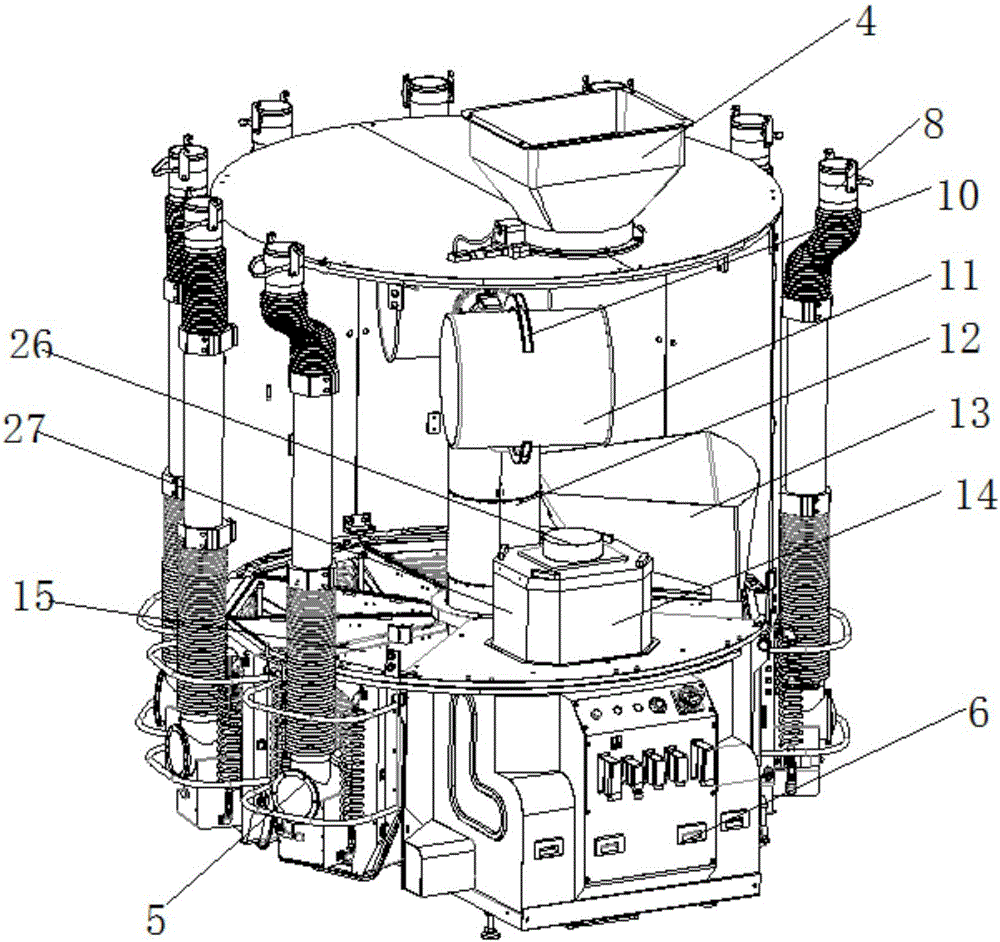

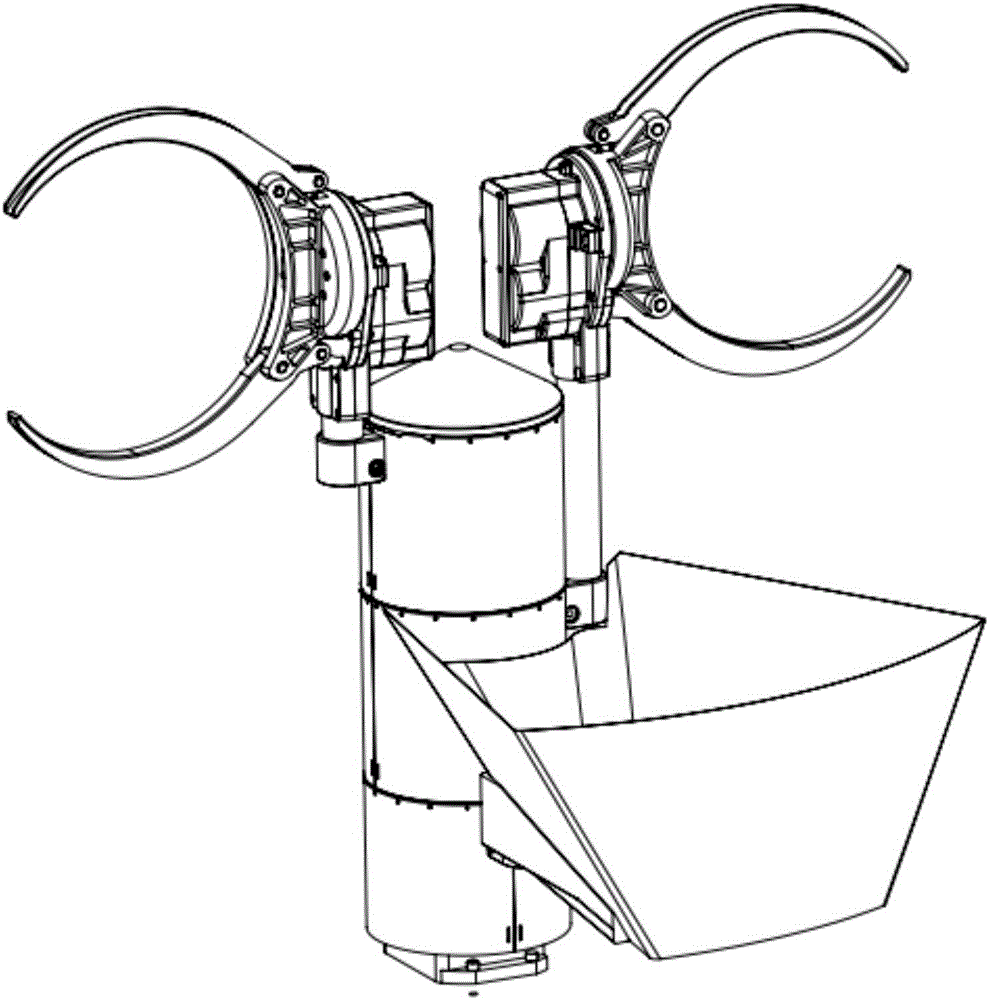

[0041] A new type of wire feeding machine, comprising a body 3, a wire suction device 5, and a power supply device 6, characterized in that, the body 3 is provided with a feed port 4, and a conveyor belt 2 is provided above the feed port 4, and the conveyor belt 2 fixedly installed on the frame 1; the body 3 is provided with a power supply device 6 and a silk suction device 5, the silk suction device 5 is provided with a silk suction port 15, and the silk suction device 5 is connected with a silk suction tube 15, and the silk suction tube 15 is provided with a quick connector 8; the thread suction pipe 15 is connected to the cigarette machine, and the cigarette machine is located in the cigarette machine room, and the cigarette machine has a certain negative pressure, so there will be a certain negative pressure on the thread suction pipe 15. The silk reel is used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com