Method for preparing margarya melanioides meat freshness-enhancing base material from margarya melanioides meat protein hydrolysate

A protein hydrolyzate, snail meat technology, applied in the fields of application, food science, food preservation, etc., to achieve the effect of removing the fishy smell of soil, enhancing the aroma, and maintaining the natural properties and flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

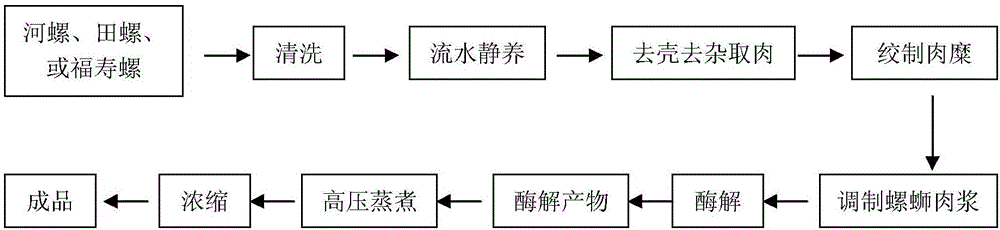

Method used

Image

Examples

Embodiment 1

[0025] 1) The raw material is river snail, also called stone snail. For river snails, wash the silt with clean water, let them rest in flowing water for 3-5 days, then remove the shells, remove impurities, get the meat, and grind them into minced meat.

[0026] 2) Mix the above minced meat with water (the weight ratio of minced meat to water is 0.25:1), and make a uniform and fine meat slurry through colloid milling, and adjust the pH value to 6.5.

[0027] 3) Add compound flavor enzyme (Flavourzyme) and neutral protease directly to the snail meat slurry prepared above, enzymolysis temperature is 50°C, enzymolysis time is 4 hours, and the degree of hydrolysis is preferably controlled at 30%. The compound flavor enzyme (Flavourzyme) is added with 6LAPU per gram of the weight of the minced meat (LAPU is the English abbreviation of leucine aminopeptidase unit); food-grade neutral protease (200,000 u / g) is added at 0.4% of the weight of the minced meat.

[0028] 4) After adding a...

Embodiment 2

[0030] 1) The raw material is snail. For the snails, wash the sediment with clear water, let them rest for 3-5 days in running clear water, then remove the shells, remove impurities, get the meat, and grind them into minced meat.

[0031]2) Mix the above minced meat with water (the weight ratio of minced meat to water is 0.3:1), and make a uniform and fine meat slurry through colloid milling, and adjust the pH value to 6.5.

[0032] 3) Add compound flavor enzyme (Flavourzyme) and neutral protease directly to the snail meat slurry prepared above, enzymolysis temperature is 50°C, enzymolysis time is 4 hours, and the degree of hydrolysis is preferably controlled at 30%. The compound flavor enzyme (Flavourzyme) is added with 8 LAPU per gram of the weight of the minced meat (LAPU is the English abbreviation of leucine aminopeptidase unit); food-grade neutral protease (200,000 u / g) is added at 0.5% of the weight of the minced meat.

[0033] 4) After adding an appropriate amount of ...

Embodiment 3

[0035] 1) The raw material is apple snails. For apple snails, wash the silt with clean water, let them rest in flowing water for 3-5 days, then remove the shells and remove impurities to get the meat, and grind them into minced meat.

[0036] 2) Mix the above minced meat with water (the weight ratio of minced meat to water is 0.35:1), and make a uniform and fine meat slurry through colloid milling, and adjust the pH value to 6.5.

[0037] 3) Add compound flavor enzyme (Flavourzyme) and neutral protease directly to the snail meat slurry prepared above, enzymolysis temperature is 50°C, enzymolysis time is 4 hours, and the degree of hydrolysis is preferably controlled at 35%. The compound flavor enzyme (Flavourzyme) is added with 8 LAPU per gram of the weight of the minced meat (LAPU is the English abbreviation of leucine aminopeptidase unit); food-grade neutral protease (200,000 u / g) is added at 0.5% of the weight of the minced meat.

[0038] 4) After adding an appropriate amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com