A kind of baby food and its production method

A vitamin, fruit and vegetable powder technology, applied in the directions of food drying, food ingredients, food forming, etc., can solve the problems of no cost, reasonable fruit and vegetable powder products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

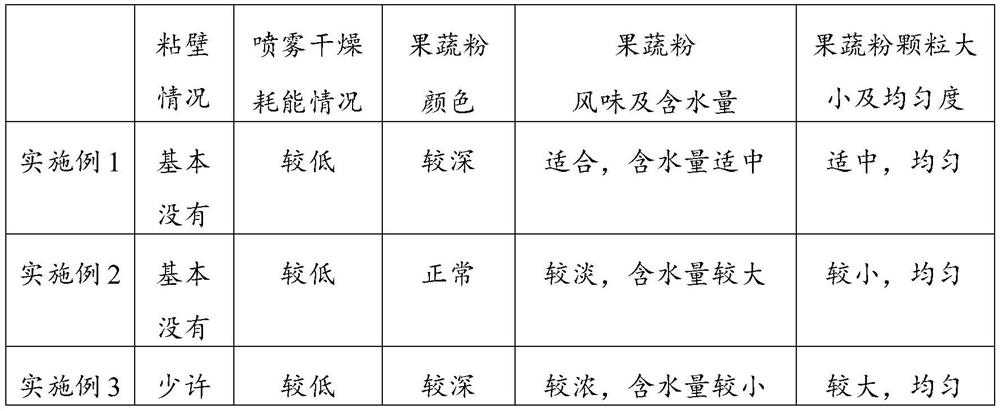

Examples

Embodiment 1

[0058] Raw material preparation: Use a 300-mesh 3000 rpm filter centrifuge to filter out tomato pulp residue to obtain 3000 kg of tomato fruit and vegetable juice. After testing, the solid content contained in the tomato fruit and vegetable juice is about 600 kg, which is about 20% of the mass of the fruit and vegetable juice.

[0059] Mixture preparation: weighing the fructo-oligosaccharides so that the mass ratio of the solids of the fruit and vegetable juices to the fructo-oligosaccharides is 1:1, and then adding the weighed fructo-oligosaccharides into the tomato fruit and vegetable juices for mixing.

[0060] Homogenization treatment: use a 40MPa homogenizer to perform a second homogenization treatment on the above mixture.

[0061] Sterilization treatment: Pasteurize the homogenized mixture by heating it to 68°C to 70°C for 30 minutes.

[0062] Spray drying: The sterilized mixture is spray-dried in a drying tower, where the inlet air temperature is set at about 145°C to ...

Embodiment 2

[0064] Raw material preparation: Use a 300-mesh 3000 rpm filter centrifuge to filter out the kiwi pulp residue to obtain 3000 kg of kiwi fruit and vegetable juice. After testing, the solid content contained in the kiwi fruit and vegetable juice is about 300 kg, which is about 10% of the mass of the fruit and vegetable juice.

[0065] Mixture preparation: weigh fructo-oligosaccharides, polyfructosaccharides and inulin respectively, so that the mass ratio of the solids of fruit and vegetable juices to fructo-oligosaccharides, polyfructosaccharides and inulin is 5:2:2:1, and then weigh the The obtained fructo-oligosaccharides, polyfructosaccharides and inulin are added to the kiwi fruit and vegetable juice for mixing. In addition, 0.1% vitamin C of tomato solids was added, and then the weighed inulin, fructooligosaccharides, polyfructosaccharides and vitamin C were added to the fruit and vegetable juice for mixing.

[0066] Homogenization treatment: use a 40MPa homogenizer to per...

Embodiment 3

[0070] Raw material preparation: Use a 200-mesh 2000 rpm filter centrifuge to filter out the kiwi pulp residue to obtain 3000 kg of kiwi fruit and vegetable juice. After testing, the solid content contained in the kiwi fruit and vegetable juice is about 1200 kg, which is about 40% of the mass of the fruit and vegetable juice.

[0071] Mixture preparation: take by weighing fructo-oligosaccharide and polyfructosaccharide respectively, make the solid matter of kiwifruit fruit and vegetable juice, fructo-oligosaccharide, and the mass ratio of polyfructosaccharide be 6:3:1, then weigh the fructo-oligosaccharide and Polyfructose is added to kiwi fruit and vegetable juice for mixing.

[0072] Homogenization treatment: use a 40MPa homogenizer to perform homogenization treatment on the above mixture twice.

[0073] Sterilization treatment: Pasteurize the homogenized mixture by heating it to 68°C to 70°C for 30 minutes.

[0074] Spray drying: The sterilized mixture is spray-dried, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com