Production technique of fermented brown rice

A production process and technology of brown rice, applied in the direction of yeast-containing food ingredients, functions of food ingredients, bacteria used in food preparation, etc., can solve problems such as disease, waste of resources, and lack of nutrition, so as to improve the taste, increase the content, The effect of preventing constipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

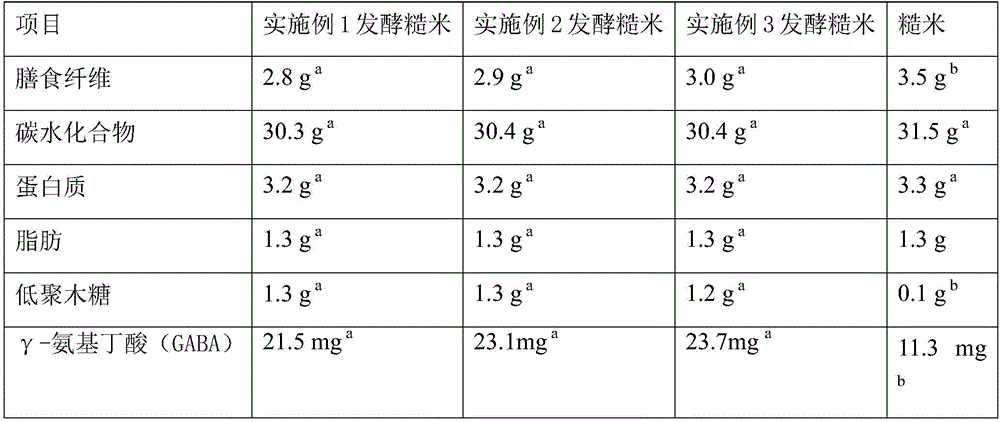

Examples

Embodiment 1

[0019] The production technology of the fermented brown rice that present embodiment provides, comprises the following steps:

[0020] (1) Cleaning and removing impurities: wash the brown rice once with clear water to remove impurities such as floating dust in the raw brown rice.

[0021] (2) Softening: Soak the cleaned brown rice in water at 25° C. for softening, and keep it for 4 hours to keep its water content at 30%. This step can soften the brown rice, which is beneficial to the subsequent fermentation reaction.

[0022] (3) Fermentation: Add 30 parts by weight of water to 100 parts by weight of softened brown rice, add 5 parts by weight of brown rice flour, and add 1 part by weight of salt; then sterilize at 90° C. for 20 minutes.

[0023] Cool the material to 30° C., inoculate 3 mL of a composite bacterial suspension with an OD value of 1 with 100 parts by weight of the softened brown rice, stir evenly, and then ferment for 5 hours.

[0024] This step degrades part of...

Embodiment 2

[0029] The production technology of the fermented brown rice that present embodiment provides, comprises the following steps:

[0030] (1) Cleaning and removing impurities: the brown rice is washed twice with clear water to remove impurities such as floating dust in the raw material brown rice.

[0031] (2) Softening: Soak the cleaned brown rice in water at 29° C. for softening, and keep it for 6 hours to keep its water content at 35%. This step can soften the brown rice, which is beneficial to the subsequent fermentation reaction.

[0032] (3) Fermentation: Add 40 parts by weight of water to 100 parts by weight of softened brown rice, add 7.5 parts by weight of brown rice flour, and add 3 parts by weight of salt; then sterilize at 92.5°C for 25 minutes.

[0033] Cool the material to 33° C., inoculate 4 mL of the composite bacterial suspension with an OD value of 1.5 with 100 parts by weight of the softened brown rice, stir evenly and then ferment for 7.5 hours.

[0034] Thi...

Embodiment 3

[0039] The production technology of the fermented brown rice that present embodiment provides, comprises the following steps:

[0040] (1) Cleaning and removing impurities: the brown rice is washed 3 times with clear water to remove impurities such as floating dust in the raw brown rice.

[0041] (2) Softening: Soak the cleaned brown rice in water at 33° C. to soften, keep for 8 hours, and keep the water content at 40%. This step can soften the brown rice, which is beneficial to the subsequent fermentation reaction.

[0042] (3) Fermentation: Add 50 parts by weight of water to 100 parts by weight of softened brown rice, add 10 parts by weight of brown rice flour, and add 5 parts by weight of salt; then sterilize at 95° C. for 30 minutes.

[0043] Cool the material to 36° C., inoculate 5 mL of a composite bacterial suspension with an OD value of 2 with 100 parts by weight of softened brown rice, stir evenly, and then ferment for 10 h.

[0044] This step degrades part of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com