A kind of modification method of glutinous rice flour special for quick-frozen glutinous rice balls and its product and application

A technology of quick-frozen glutinous rice balls and glutinous rice flour, which is applied in food science and other fields, can solve food safety and non-conformity problems, and achieve the effects of improving processing performance, increasing elasticity, and reducing water loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Processing of glutinous rice flour samples

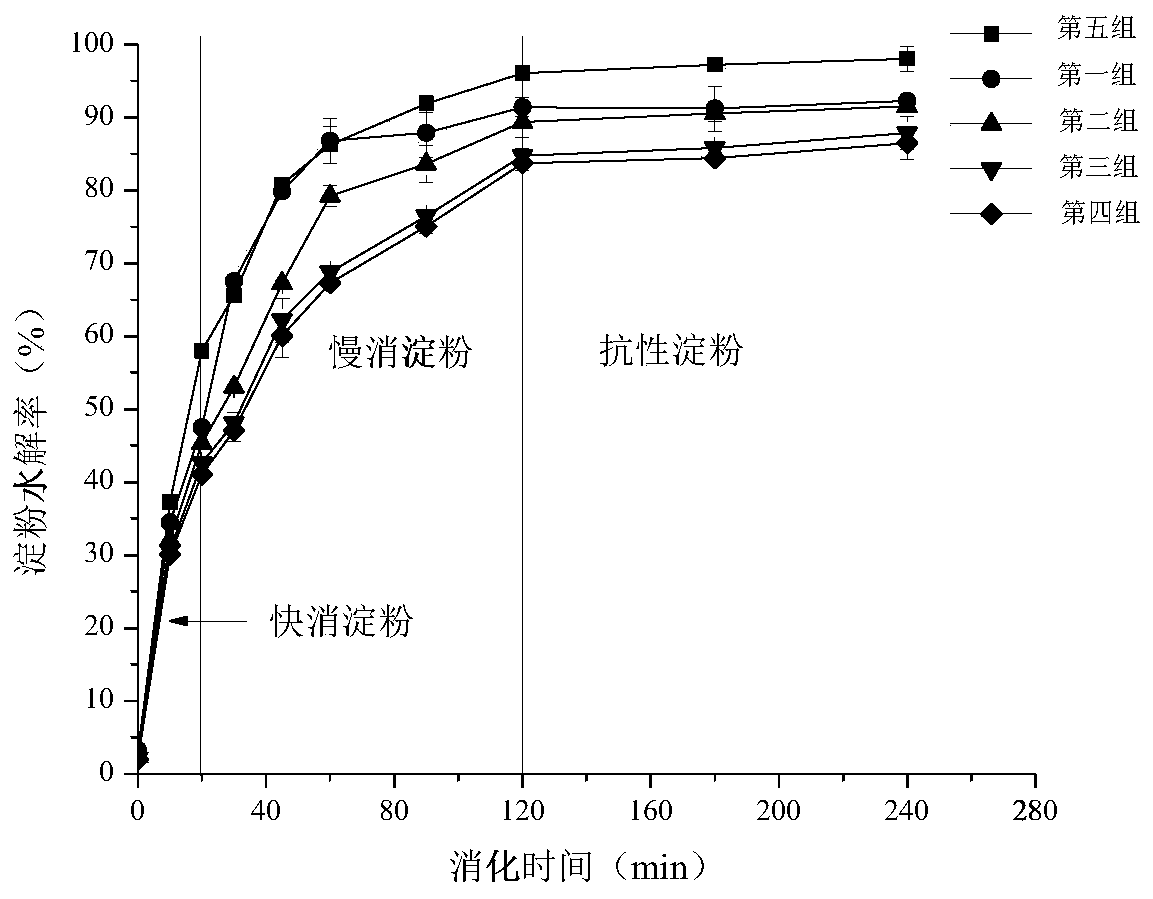

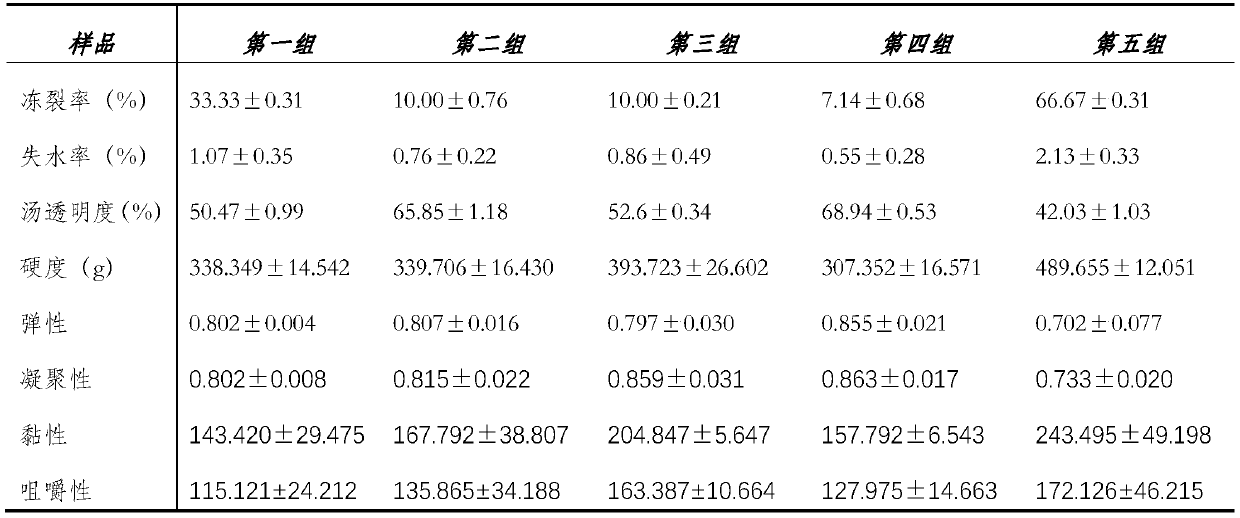

[0030] [First group] Take 200g of glutinous rice flour, add 200mL of deionized water to make the water content 50%, stir in a constant temperature water bath at 55°C at 100r / min for 5h, centrifuge at 3000r / min for 20min, remove the supernatant and then vacuum dry After 6 hours, the vacuum degree is 0.08MPa, the temperature is 40° C., and after crushing and passing through a 120-mesh sieve, the treated glutinous rice flour is obtained. The processed glutinous rice flour was used to make quick-frozen glutinous rice balls, and its quality was evaluated according to the evaluation method of quick-frozen glutinous rice balls. The evaluation results are shown in Table 1 and figure 1 .

[0031] [Group 2] Take 180g of glutinous rice flour, add 220mL of deionized water to make the water content 55%, stir in a constant temperature water bath at 50°C at 100r / min for 5h, centrifuge at 3000r / min for 20min, remove the supernatant and then...

Embodiment 2

[0037] Effect of Modified Glutinous Rice Flour on the Quality of Glutinous Rice Balls

[0038] [1] Prepare glutinous rice balls

[0039] Take 100g of glutinous rice flour and add water with a dry basis content of 95%, mix well, knead the dough until the surface is basically smooth, and let it stand for 20 minutes. Take about 10g of the prepared dough, round it and put it on a plate, freeze it at -30°C for 30 minutes, so that the center temperature of the glutinous rice balls will drop to -18°C quickly, take it out, and store it at -18°C.

[0040] [2] Quality evaluation of quick-frozen glutinous rice balls

[0041] The quality evaluation indicators of quick-frozen glutinous rice balls include freezing cracking rate, water loss rate, paste soup rate after cooking and texture characteristics.

[0042] Frozen cracking rate: the ratio of the number of glutinous rice balls that are frozen and cracked after storage for a certain period of time to the total number of glutinous rice ...

Embodiment 3

[0053] Study on Digestibility of Modified Glutinous Rice Flour

[0054] [1] Experimental method

[0055] Starch digestion characteristics: Take 1 steamed glutinous rice ball, add distilled water 10 times the weight of the glutinous rice ball, and mash it with a tissue grinder. Take 5mL for the determination of starch hydrolysis rate. The determination method refers to the Englyst method.

[0056] Digestion specific assessment results such as figure 1 .

[0057] Depend on figure 1 It can be seen that the digestion characteristics of starch are improved, and the glycemic index is significantly reduced. Among them, the content of fast digestible starch is reduced by 10.51% to 15.39%, the content of slow digestible starch is increased by 4.07% to 5.98%, and the content of resistant starch is increased by 4.69% to 11.33%. Therefore, using the method of the invention can improve the digestion properties of the quick-frozen glutinous rice balls, reduce the content of slowly dige...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com