A kind of swimming crab liquid nitrogen quick freezing equipment

A liquid nitrogen quick-freezing and swimming crab technology, which is applied in the direction of freezing/cooling preservation of meat/fish, etc., can solve the problems of large residual liquid nitrogen, waste of cooling capacity, uneven freezing, etc., and achieve improved liquid nitrogen atomization and uniform spraying of liquid nitrogen , the effect of reducing the temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

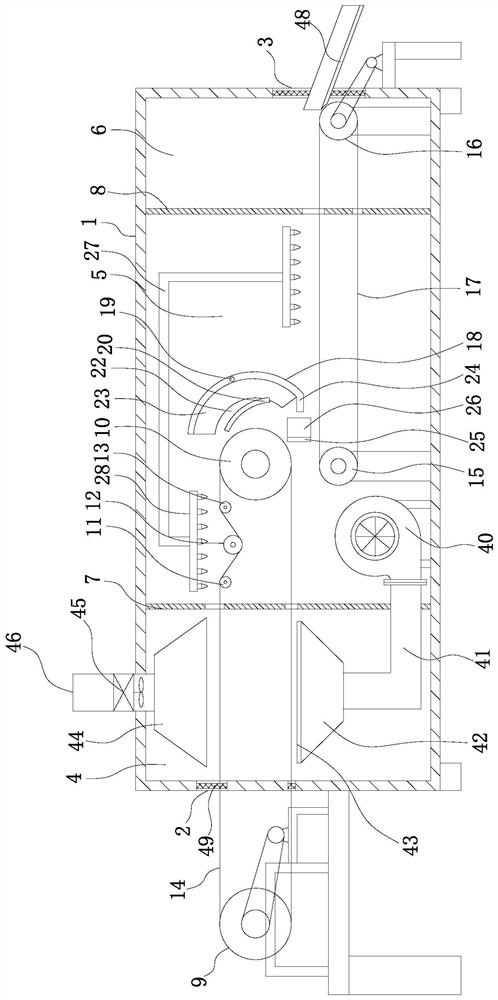

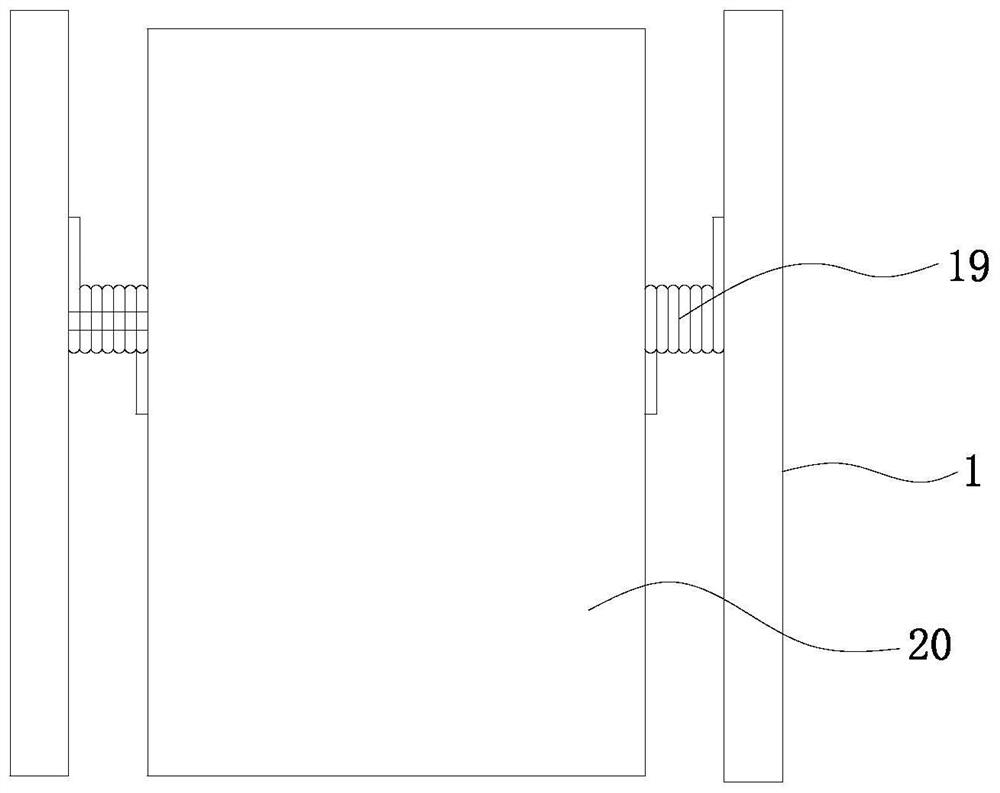

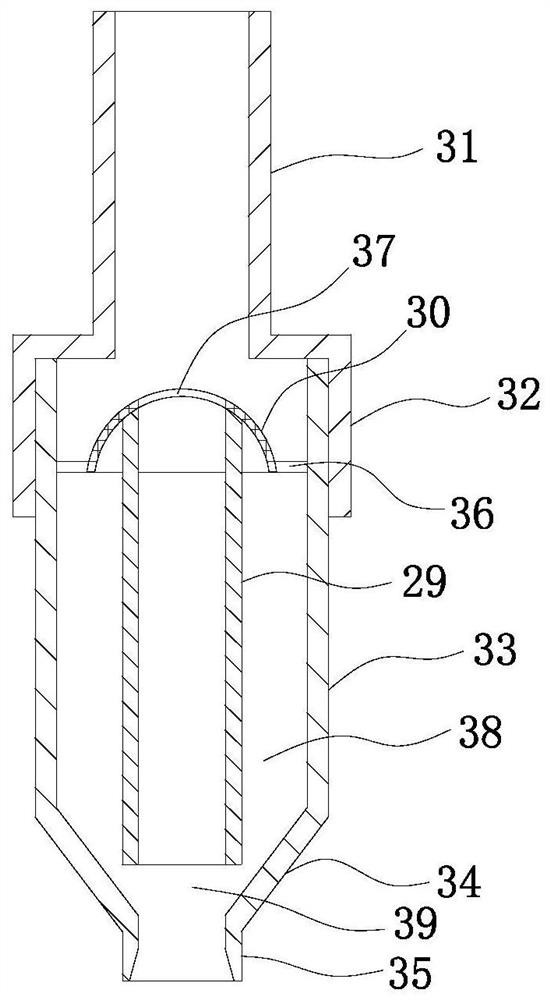

[0029] Such as figure 1 The liquid nitrogen quick-freezing equipment for swimming crabs shown includes a heat-insulated, tunnel-type box body 1, a feeding conveying mechanism, a material discharging conveying mechanism and a low-temperature nitrogen recovery mechanism. The feed opening 3, the front partition 7 and the rear partition 8 that divide the inner space of the cabinet into a pre-cooling chamber 4, a freezing chamber 5 and an equalizing room 6 are fixed in the cabinet, and the feeding transmission mechanism includes an active conveyor located outside the cabinet. Feed roller 9, passive feed roller 10, front guide roller 11, lower guide roller 12 and rear guide roller 13, the active feed roller is driven by the first reduction motor located outside the box and fixed on the frame, and the passive feed The drum, the front guide roller, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com