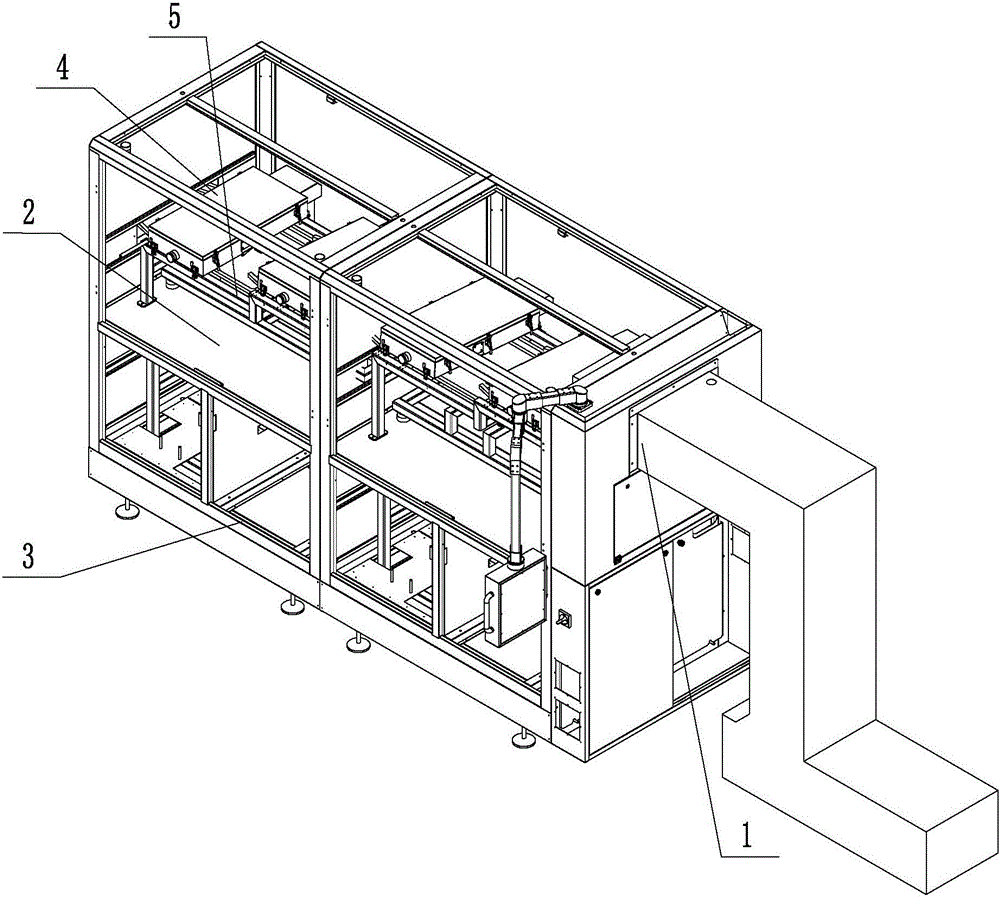

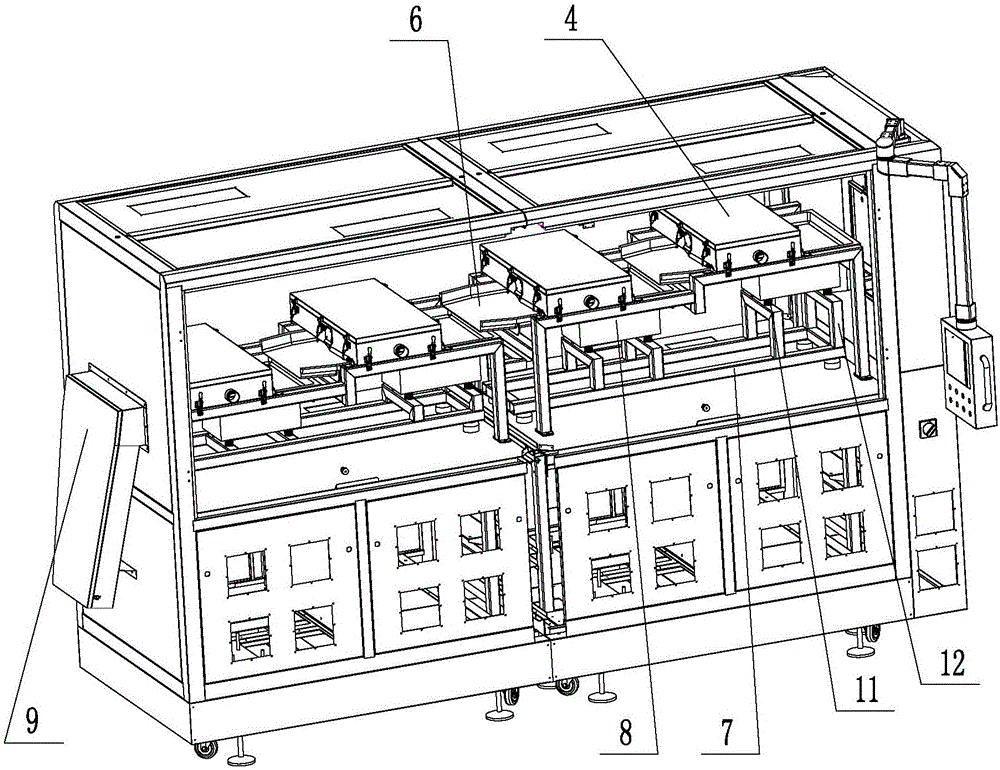

Pulse sterilization equipment for solid material granules

A solid material and sterilization equipment technology, applied in the fields of application, food science, food preservation, etc., can solve the problems of unsatisfactory double-sided sterilization effect and low turning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 100 parts of unsaturated polyester paint, 2.5 parts of metal carboxylate, 8 parts of silicon nitride, 2 parts of acrylic resin, 1 part of antifoaming agent, 2 parts of polyethylene terephthalate, and 1 part of nano calcium carbonate.

Embodiment 2

[0026] 100 parts of unsaturated polyester paint, 3 parts of metal carboxylate, 9 parts of silicon nitride, 6 parts of acrylic resin, 4 parts of antifoaming agent, 4 parts of polyethylene terephthalate, 4 parts of nano calcium carbonate.

Embodiment 3

[0028] 100 parts of unsaturated polyester paint, 3.5 parts of metal carboxylate, 10 parts of silicon nitride, 8 parts of acrylic resin, 6 parts of defoamer, 5 parts of polyethylene terephthalate, 5 parts of nano calcium carbonate.

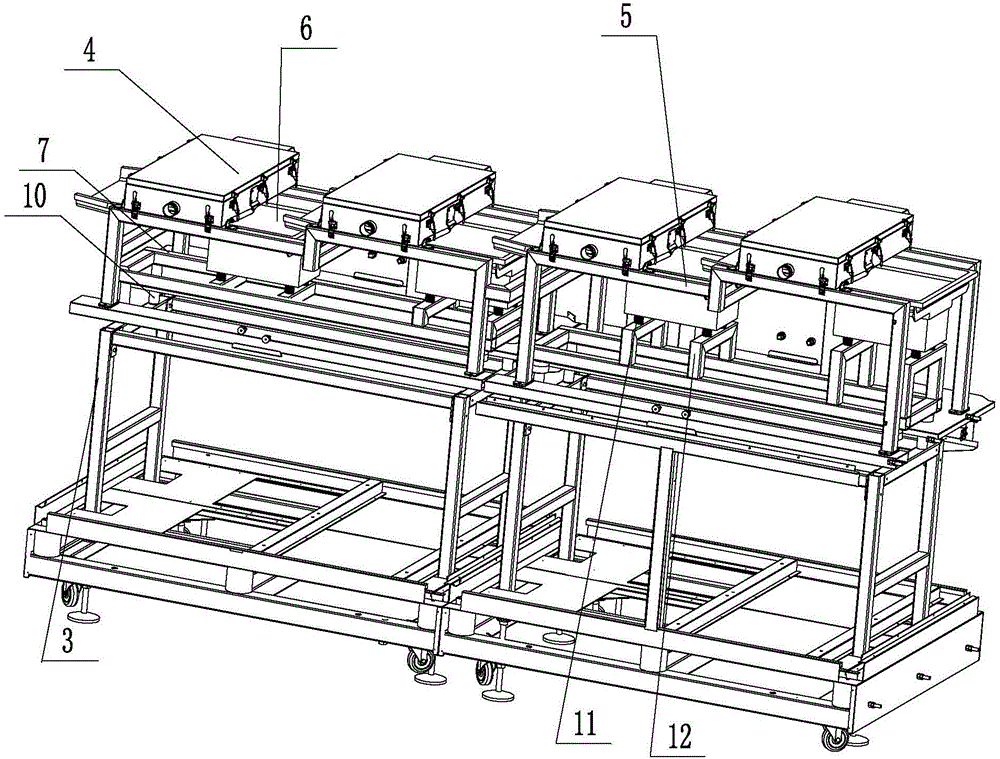

[0029] When making the mirror aluminum plate, the substrate is rolled, polished, and baked, and then the coating paint is configured by the weight ratio of the above-mentioned raw materials, and the paint is evenly coated on the substrate, and the finished product is second baked . The design of the above-mentioned mirror surface aluminum can reflect the irradiated light and shine on the backlight surface of the solid particles, thereby increasing the sterilization area for sterilization. At the same time, due to the vibration of the conveying tray, the solid particles will not stick to the conveying tray. At the same time, the backlight surface is easier to receive the reflected light, and there is a chance that the solid particles will turn over. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com