Split combined type flowerpot

A combined type and flowerpot technology, applied in gardening, botany equipment and methods, container cultivation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

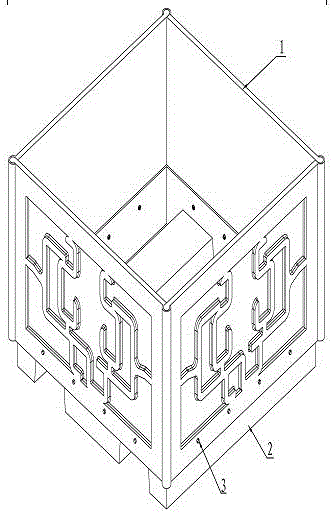

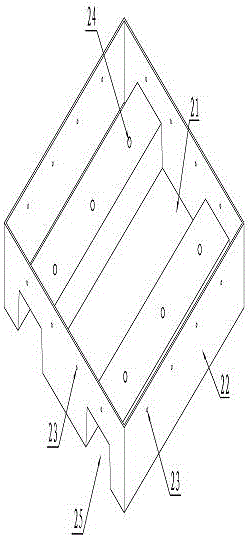

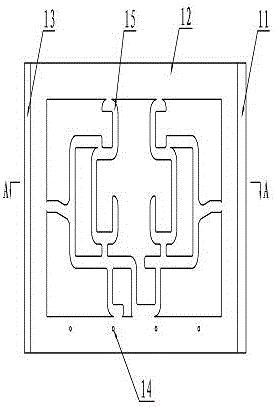

[0013] Embodiment 1: A split combined flower pot, which is composed of four boards 1, a square flower pot support 2 and sixteen connecting bolts 3, the four boards 1 are the same, and the boards 1 include connecting notches 11. The plate body 12, the connecting convex body 13 and the chassis connection hole 14, the connecting notch 11 and the connecting convex body 13 are respectively arranged at both ends of the plate body 12, and the shape of the cross section of the connecting notch 11 is an open circle, and the connecting The cross-sectional shape of the convex body 13 is circular with a handle, and the connecting convex body 13 is inserted into the connecting notch 11, and there is a clearance fit between the two. The material of 1 is plastic-wood composite material. In order to improve the strength of board 1, reduce the material used for the board, and enhance the aesthetic feeling and cultural connotation of the board, a reinforcing rib 15 is provided on the outer surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com