Orientating, spike-picking and peel-stripping device for corn bionic harvesting

A corn and peeling roller technology, applied in threshing equipment, agriculture, application, etc., can solve the problems of corn ear omission loss, bract leaves hindering corn threshing, damage, etc., to improve the efficiency of peeling operations, improve the accuracy of ear picking, reduce the The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

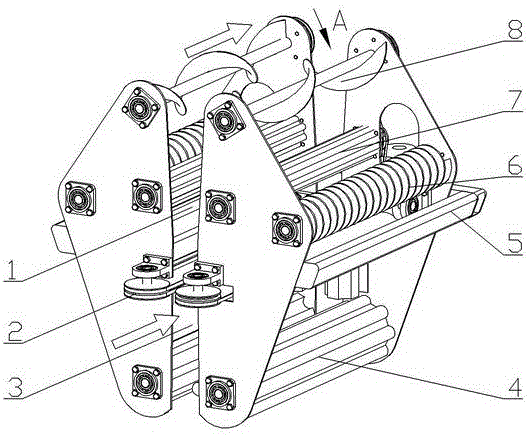

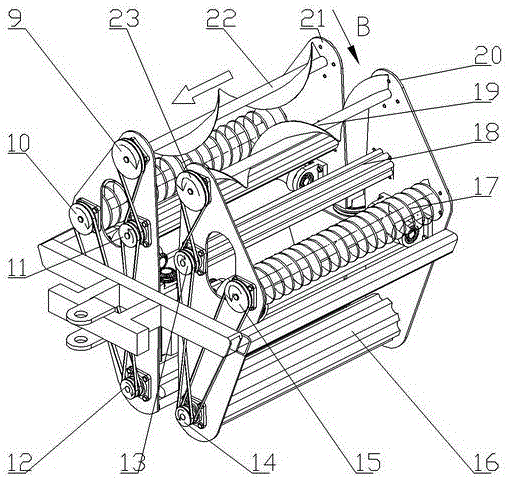

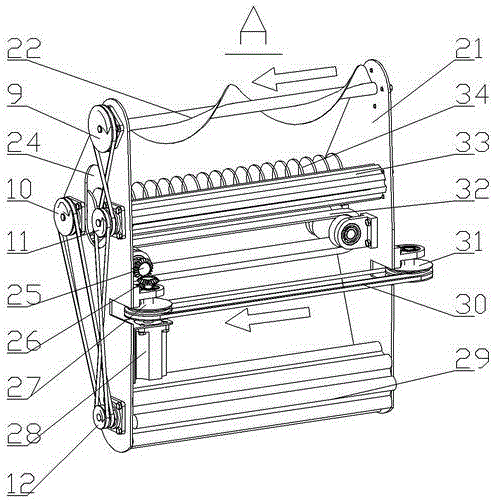

[0018] see figure 1 , figure 2 , image 3 and Figure 4 Shown, the present invention includes orientation mechanism 8, fringe picking mechanism 7, peeling mechanism 6, delivery mechanism 1, clamping mechanism 2, stem pulling mechanism 4 and frame 5, and orientation mechanism 8 is fixed on the top of frame 5, picks The fringe mechanism 7 is fixed above the middle part of the frame 5, the peeling mechanism 6 is fixed outside the middle part of the frame 5, the conveying mechanism 1 is fixed below the middle of the fringe picking mechanism 7 and the peeling mechanism 6, and the clamping mechanism 2 is fixed on the frame 5 Below the middle part, the stem pulling mechanism 4 is fixed on the bottom of the frame 5; the orientation mechanism 8 includes a left auger pulley 9, a left-handed directional auger 22, a right auger belt pulley 23 and a right-handed directional auger 19, and a left-handed directional auger 19. The auger 22 is installed on the top of the left frame 21, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com