Method for picking model type crystal particle

A grain and pacesetter technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as slow speed, misselection of grains, and poor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to enable the technical features of the invention to be further understood, the following detailed descriptions are hereby proposed:

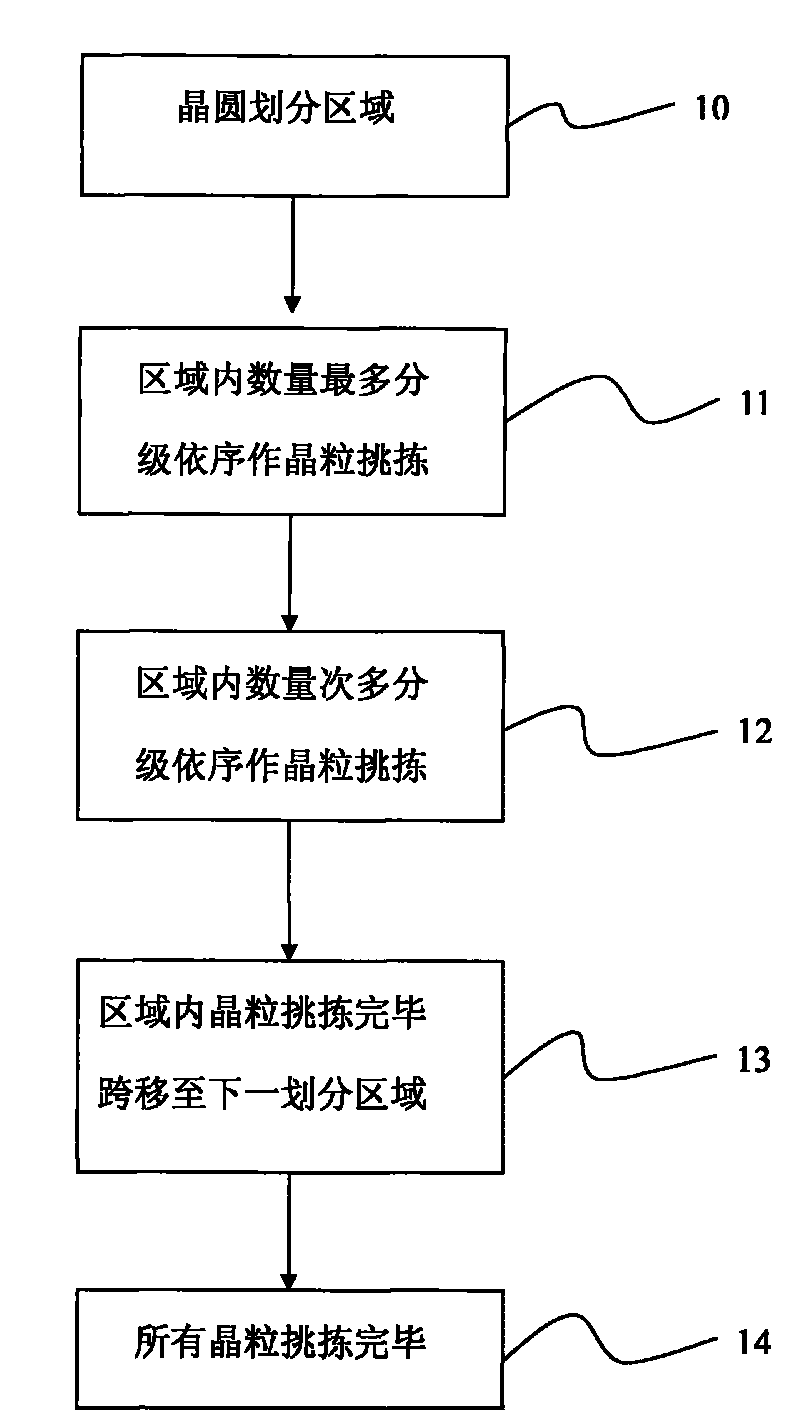

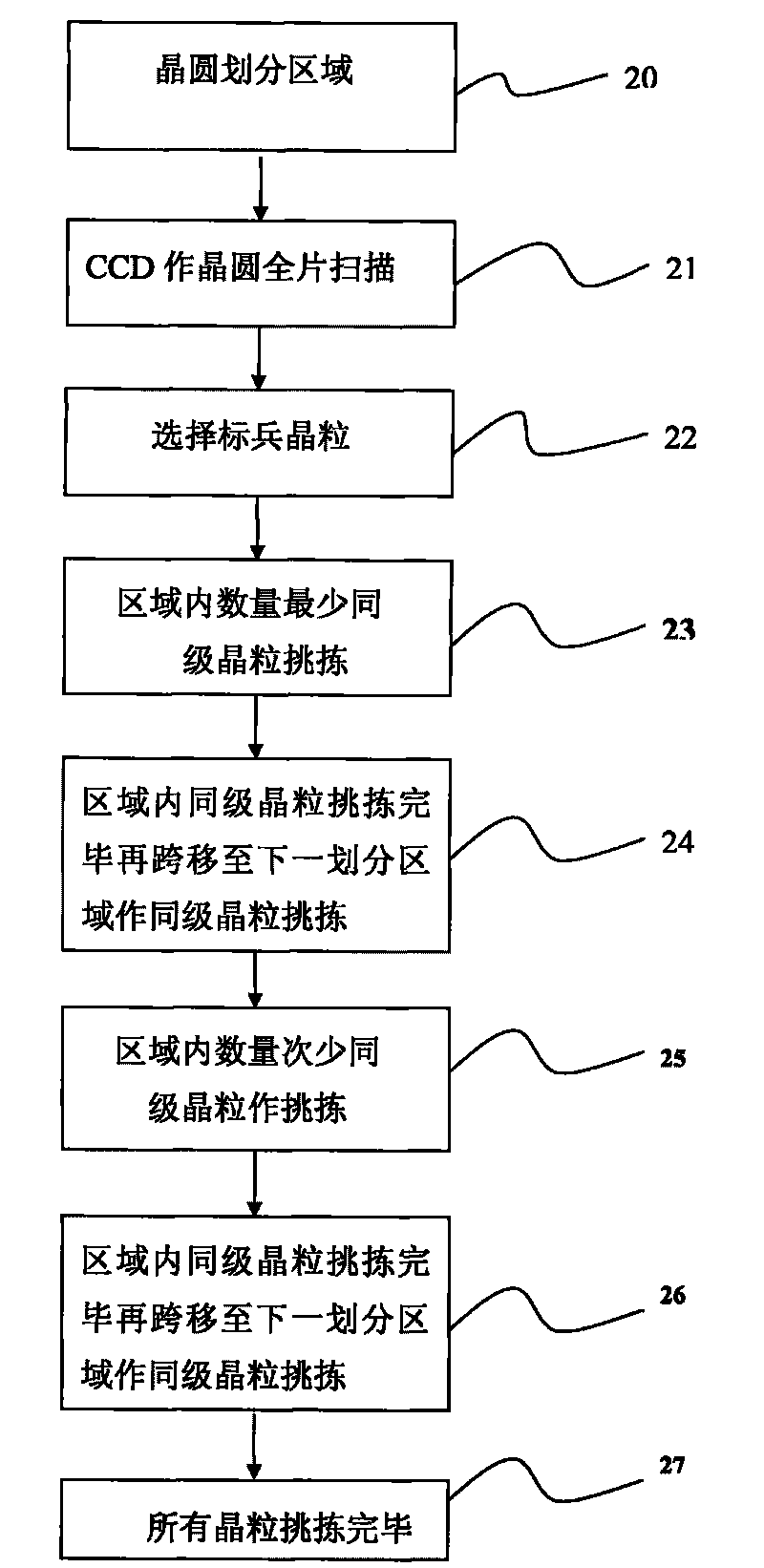

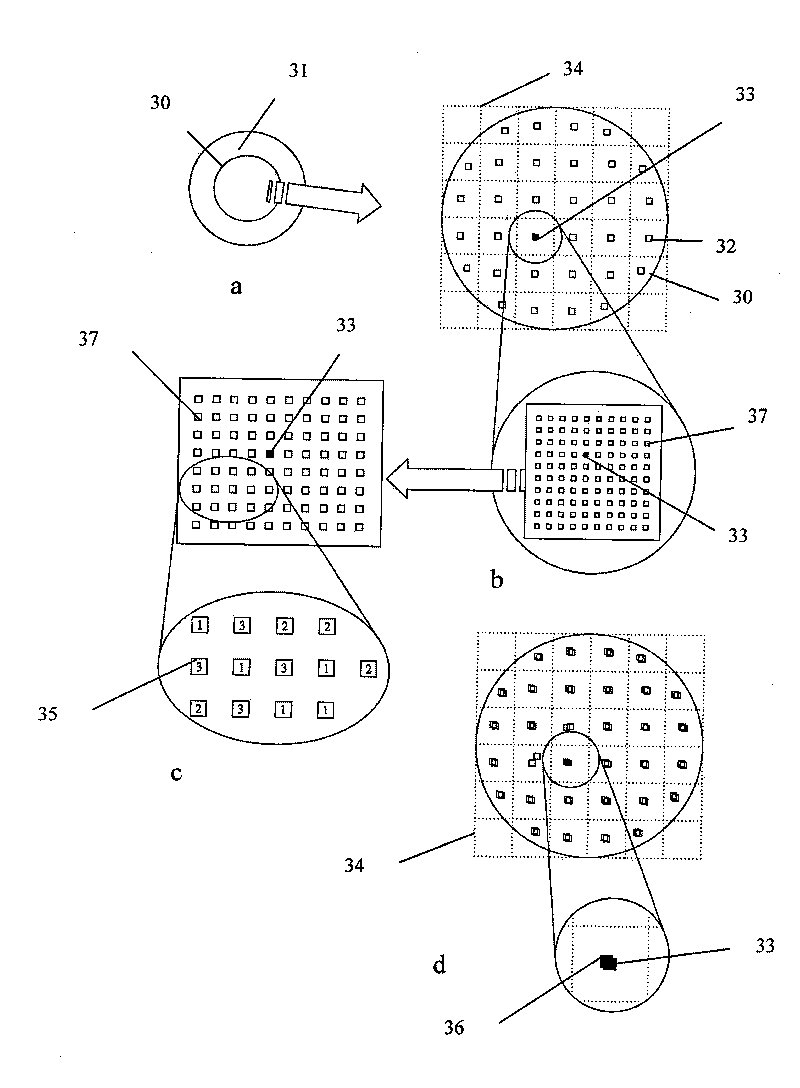

[0049] see figure 2 (Please also refer to image 3 ), this figure is the grain sorting flowchart of the present invention, and its method step mainly comprises:

[0050] Step 20: Divide the wafer into a plurality of divided regions to form a wafer pattern.

[0051] Step 21: Use the CCD to scan the entire wafer pattern to record the relative positions and grades (Bin) of all dies.

[0052] Step 22: Selecting model grains in all divided areas according to the set conditions as a guidepost for grain picking.

[0053] Step 23: Start sorting from the grains of the same level (Bin) with the smallest total number among all levels of grains (Bin) in the wafer pattern.

[0054] Step 24: After sorting the same-level (Bin) grains in the initial division area, move to the pacesetter grains in the next division area, and do the same-level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com